Aluminum heating radiators: design features and an overview

Information on how to choose aluminum radiators of heating will be useful to anyone who plans to engage in independent arrangement of the heating system. Knowledge of technical parameters and operational features will not be superfluous: aluminum batteries, especially high-quality ones, are quite expensive, so it is better to learn all the nuances in advance than to overpay or purchase an inappropriate device.

In this article we will describe how aluminum heating radiators are made, what are their pros and cons, and also give a description of several fairly popular models.

Battery design

General characteristics

Water and steam heating of rooms is carried out using radiators - structures that provide the most efficient redistribution of energy from the coolant to the environment. Radiators are systems of pipes with plates of material with good thermal conductivity (usually metal) attached to them.

The aluminum radiator has a typical design for such devices:

- Inside the product are pipes, which under pressure passes hot water, acting as a coolant.

- The channels are placed in such a way that the coolant goes a long way inside the radiator - more heat will enter the environment. To further optimize this process, gaps for air penetration are usually left between adjacent pipes.

- For more efficient energy dissipation, pipes are supplied with additional radiator plates.. The structure, thickness and configuration of such plates are different from different manufacturers, because very often aluminum heating radiators of approximately the same size differ greatly in their thermal characteristics.

Most often, batteries are assembled from separate sections (sometimes called ribs), which are hermetically interconnected. This is quite convenient, because by changing the number of ribs we can adjust the power of the heating system in a particular area.

However, sometimes there are also panel regulators, in which pipes and diffusing plates are assembled into a single case.

Production methods

Despite the fact that aluminum radiators for heating entered the market relatively recently - around the 70s of the last century - they had already gained enough popularity. The volume of production of such products is constantly increasing, which leads to continuous improvement of technology.

Today, there are three main methods of manufacturing batteries from aluminum:

| Method | Specifications |

| Casting | The material used is silumin - aluminum with the addition of silicon (up to 12%, which provides an increase in mechanical strength). The casting process is carried out under increased pressure. Depending on the wall thickness, this method can be used to obtain either standard radiators (6 atmospheres) or reinforced (15-20). Most often, casting make separate sections, which are then combined in an arbitrary number depending on the tasks. |

| Extrusion | The extrusion method usually produces flat parts, which are then assembled together with a collector obtained by the injection molding method. During extrusion, the melt silumin passes through a forming device — a spinneret. The result is a part with a clear profile of fixed dimensions. Further assembly of the elements to obtain the actual radiator is carried out by pressing. The use of extrusion significantly reduces the cost of production, but in such a radiator can not add additional sections. |

| Anodizing | Anodizing is, rather, not a method of production as such, but a method of processing the finished product. At the same time, a layer of inert oxides is applied to the surface of silumin, which not only protects the metal from corrosion, but also makes it smooth.

|

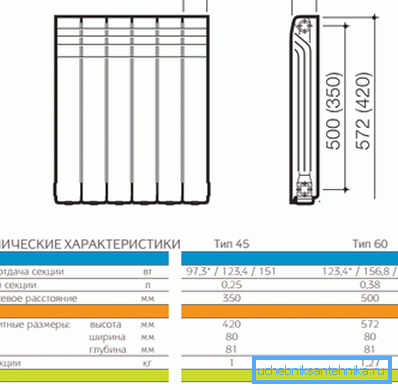

Performance parameters

The dimensions of aluminum radiators are the main factor that influences their power. Typically, manufacturers produce models with a distance between the axes of 200, 350 and 500 mm, which allows you to install batteries either under the windowsill (dimensions provide sufficient gaps) or directly above the floor.

Note! If necessary, you can purchase more dimensional models: the maximum value in the dimensional grid of most manufacturers is 800 mm.

Other technical characteristics of aluminum radiators are as follows:

- Working pressure - from 6 to 16 atmospheres depending on the configuration of the internal collector and wall thickness.

- Compression pressure - up to 20 atmospheres.

Note! In apartment buildings with a centralized heating system, the pressure increase during the pressure testing of the system can reach up to 30-40 atm. Aluminum structures often do not withstand such a load, which leads to gusts with very unpleasant consequences. That is why the described type of radiators is recommended for use mainly in private homes.

- The mass of one section of the radiator is 1 -1.5 kg.

- The maximum allowable water temperature is 110 C.

- Heat transfer - from 80 to 220 watts.

- Warranty period - from 10 to 15 years.

Naturally, these are only averaged parameters. More detailed information on the characteristics of the model chosen by you usually contains instructions from the manufacturer.

Evaluation of user qualities

Merits

The advantages of aluminum heating structures include the following:

- The good thermolysis providing decrease in costs of heating of the room.

- Low weight, making it easy to do your own hands.

- The ability to connect teploreguliruyuschego equipment.

- Attractive appearance of most models.

disadvantages

If we talk about the cons, they too.

Of course, most of them are not an obstacle to the successful use of aluminum radiators, but you must be aware of these disadvantages:

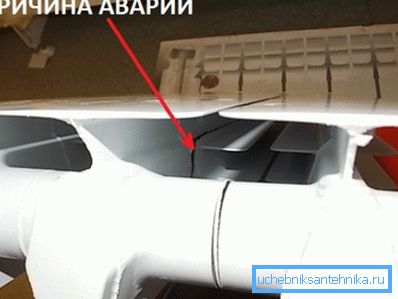

- At the junction of sections, as well as at the junction of the radiator and the pipe leakage is possible.

Note! Strongly drag the connecting coupling is not worth it, because silumin can crack. In this case, the repair of aluminum radiators will be almost impossible: the material does not weld and cannot be soldered. So what will be the only complete replacement parts.

- Contact with polluted water with a high alkali content may cause corrosion and the formation of internal deposits.

- The walls of the radiator do not tolerate strong pressure drops and can be deformed.

- The price of products is quite high.

Aluminum Radiator Market Overview

Now that you know all the advantages and disadvantages of the design, you can proceed to the overview of the models on the market. The range of batteries is very wide: there are both quite expensive, but very high-quality products (Germany, Italy, Czech Republic), and quite affordable ones (Slovakia, Belarus, Russia).

China, as always, stands alone: the batteries produced in this country are quite cheap, but their quality is very unstable.

As for specific brands, you can pay attention to such:

- Nova Florida (Italy) - one of the best lines on the market. Italian radiators with internal anodizing are characterized by high (up to 185 W) heat emission, good corrosion resistance, and are also able to withstand pressures up to 20 bar. Warranty from the manufacturer for all operational failures is from 10 to 20 years, depending on the model.

- Global (Italy) is another worthy mark. The main difference of this line is an extended dimensional grid: in addition to standard batteries with a center distance of 500 mm, you can find two-meter heating panels that provide heat transfer section at the level of 450-500 watts.

- Fondital (Italy) - as well as the two previous versions, are produced by compression casting technology. The products are characterized by high enough, as for standard models, heat transfer - 210 W per section 0.5 m high. Among other advantages, we can distinguish a modular design, improved seals and a relatively small mass.

- Radena (Italy). The cost of such devices is slightly above average, but experts do not have any questions about the quality: the batteries hold the working pressure well up to 16 bar, have heat emission in the region of 170 - 195 W and resist corrosion quite well.

- Oasis (RF) - decent domestic products, which are produced by extrusion technique. Batteries have a good service life (from 15 years) as well as moderate cost.

Note! There is another "Oasis", the Chinese. Despite the significantly lower price, you should not buy radiators of this brand - the quality is very unstable. Therefore, there is a very high risk of installing a defective product, which will flow at the first pressure surge.

- Termal (RF) - another domestic brand. Radiators of sectional type are produced in a fairly wide dimensional grid. Products have good performance (operating pressure up to 22 Bar, heat transfer 160-170 W).

Conclusion

Aluminum radiators for heating have a very impressive list of advantages. So, with the right model selection and compliance with the installation rules, the product will work long enough and efficiently. If you are interested in this type of battery, then you can study it in more detail by viewing the video posted on the page.