Aluminum or cast iron radiator: selection and comparison

Heating is one of the most important life support systems, especially in our country, where the cold dominates for six months or more per year. It depends on him how comfortable and cozy our dwelling will be during the autumn-winter period. And here the question is already important, from which materials the heating devices are selected.

Market offers heat engineering

In the heating system, each element is important:

- The node supply of coolant to the network.

- The layout of pipelines, feed and reverse.

- Heating devices - radiators.

- The method of circulation of the coolant.

Residents of high-rise buildings, getting apartments with ready-made heating, do not think about how heat comes to their homes. Maybe only after tens of years, when the heating system starts to falter.

And in the case of private construction, all the issues of heating the house are decided by the owner. And one of the most important is the choice of heating devices. If you want to know which heating radiators are better - cast iron or aluminum, then you should understand the features of each particular option.

The modern range of radiators has increased significantly over the past decade. Today, the consumer is offered a wide range of heaters in all areas:

- Production material:

- Cast iron.

- Steel.

- Aluminum.

- Bimetallic.

- The form of execution:

- Panel (flat).

- Sectional.

- Tubular.

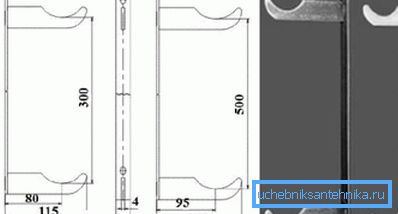

- Dimensions:

- Low from 150 mm to 450 mm.

- High (more than 450 mm).

- Place and installation options:

- Wall mounted.

- Outdoor.

- Hidden.

All characteristics except the first relate more to the aesthetics of the premises and serve to maximize fusion with the overall design.

The highest value in terms of efficiency in a particular heating system has the metal from which the battery is made. That is why the primary issue in the design of heating, which is better aluminum or cast iron radiators.

Cast iron heating devices

Traditionally, the best choice among radiators was considered to be cast iron batteries familiar to most of our fellow citizens. It is understandable, because with them began the history of heating.

It will not be superfluous to once again list all the advantages of cast iron batteries:

- High corrosion resistance. Cast iron is weakly active to the aggressive effects of acids and alkalis.

- Cast iron is not subject to mechanical wear from abrasive impurities in the coolant.

Tip! For these reasons, cast iron radiators are recommended to be installed in centralized heating systems, where the coolant has a very doubtful quality.

- The above properties provide cast iron heating appliances with a guaranteed effective service life of 30 years..

Interesting! From experience, many of us can witness the 40-year-old and older uninterrupted operation of cast iron radiators, of course, with proper care.

- Long-term preservation of heat and its release into the space of the room when the supply of hot water is turned off (coolant).

- Relatively low cost of batteries.

Weaknesses are also available:

- Big weight of the designs, complicating installation by the hands.

- The bulkiness of the batteries.

- Not exactly an attractive look, difficult to match with modern design styles.

- The high thermal inertness of cast-iron appliances does not allow them to be used in automatically regulated heating systems.

Aluminum heating radiators

Rapidly gaining popularity in the domestic market heat engineering, the first alternative to cast iron and steel appeared aluminum appliances. The aesthetically attractive appearance of aluminum batteries immediately changed our understanding of the possibilities for the participation of the heating system in the design of premises.

Note! The available instruction for connection and installation allows you to personally assemble the house heating network from aluminum radiators without any titanic efforts.

Almost flat and lightweight aluminum batteries are available in two ways:

- Extrusion, that is, more simply, extrusion. Thus, individual elements of the radiator (collector and sections) are made, which are then assembled into a single press-fit design.

- High pressure casting. The thick walls of such a device are highly durable and are able to cope with the working pressure in the heating system from 6 to 16 atmospheres. In addition, this method of manufacture allows you to produce products of various forms.

All aluminum heating appliances feature the following features:

- Very high heat dissipation.

- Short term warm up.

- Small volume and in this regard, the efficiency of the system (less water required for filling).

Note! One section of the aluminum battery is filled with only 700-1000 ml of water. This parameter for the cast iron section of the radiator is almost four times more.

- Small weight and dimensions make it easy to do it yourself.

- These batteries work well in systems with automatic regulation..

- The price of aluminum batteries directly depends on the parameters of the working pressure for which it is designed. With increasing pressure increases the cost of the device.

The disadvantages of aluminum radiators include:

- Increased corrosion tendency.

Tip! Aluminum immediately interacts with copper and copper containing pipes and fittings, so it is best to use steel or stainless steel.

- Also, high demands are placed on the quality of the coolant (a certain acidity and cleaning of mechanical impurities).

- Low resistance to mechanical impact type.

Weigh the pros and cons

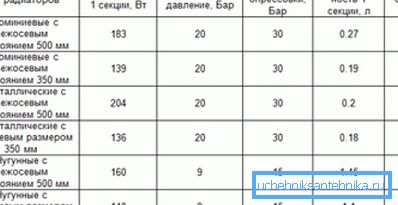

We summarize the information obtained in order to decide which radiator is better than aluminum or cast iron:

- For central heating systems in urban environments, cast iron batteries are the most suitable.

- It is undesirable to use aluminum heating devices in apartment buildings with central heating for the following points:

They are vulnerable to:

- Hydro and pneumatic impacts, often occurring at the start of a centralized heating system.

- Pressure surges (especially upward) characteristic of these systems.

- The chemical activity of aluminum and compliance with the mechanical action of abrasive impurities in the coolant requires serious water treatment.

In the conditions of private housing, where in a closed loop autonomous heating system, it is easy to provide a high level of water purification, aluminum devices will be very useful. In addition, it will help reduce the required amount of coolant.

We hope, having familiarized with this material, it will be a little easier for homeowners to decide which aluminum or cast iron radiator is better to choose for a particular case.

Bimetallic radiators

Do not limit your choice and consider only aluminum or cast iron radiators. There is a universal type of radiators that are suitable for various types of heating systems - bimetallic. These batteries successfully combine the best qualities of all known radiators.

Conclusion

We tried to give as much information as possible about which of the presented options is most suitable for residential premises. But do not confuse that the advantages of a particular type become disadvantages in a variety of situations, it is important to take into account the many nuances, up to the size of the heated area.

In the presented video in this article you will find additional information on this topic.