Aluminum radiator 500: types, production methods and

In most private homes, the heating system is independent. As heaters, aluminum devices are most often used, the technical characteristics of which make it easy to maintain a comfortable air temperature in the house, and the connection scheme is designed for a center distance of 500 mm.

Below we will understand the reasons for the popularity of such devices among the owners of private homes, as well as their features. You will learn about the types and methods of production, technical parameters and selection rules.

Types and method of production

Since aluminum is a rather soft metal, it is not used in pure form for making radiators. To ensure the strength of the devices, the alloy is diluted with special silicon additives, and the mass already obtained is used for the production of both individual sections and collectors.

Most often, the manufacture uses two main methods:

| Casting |

|

| Extrusion |

|

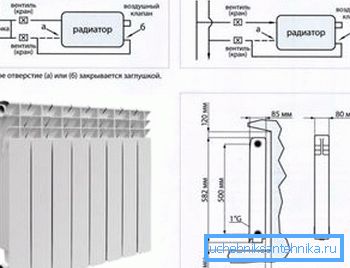

Let's consider the type of radiator 500 by 80 - what is it:

- 500 mm - the distance between the centers of the collectors;

- 80 mm - width of one section.

Anodized type battery

- The production process of products of this type is quite complicated.

- For the manufacture of such batteries used high-quality purified aluminum.

- Finished radiators anodize, thereby changing the structure of the metal, which increases its resistance to corrosion.

- In order to increase heat transfer, the internal space of the radiators is made absolutely smooth. To achieve this effect allows the fact that all parts of the radiator are connected to the outside of the couplings.

Due to the special method of metal processing and the internal structure, such devices are able to resist the exorbitant loads reaching 70 bar. However, their price is affordable not for every consumer.

Technical parameters of aluminum radiators

The distance between the collectors (axes)

In the names indicated on the packages of radiators, there is always a figure designating the center distance. As a rule, these values are standard and equal, both 200 mm and 350 mm, and 500 mm. However, other radiators are also available, in which the distance between the collectors varies from 200 mm to 800 mm.

Tip: before purchasing a device, measure the height of the section between the window sill and the floor where it will be installed.

Aluminum and bimetallic radiators 500 are not recommended to be mounted close to any surface. This can significantly impede the circulation of hot air, resulting in reduced battery efficiency.

Tip: when installing the radiator of the heating system, you need to ensure that at least 100 mm of free space remains from the sill and floor to the radiator. From the wall, the radiator must also separate a space of about 30 mm.

About thermal parameters

A significant part of heat transfer radiator is radiant heat transfer or radiation. The rest of the heat is transferred to the air by convection or mixing of air masses. Due to the special structure of the heating radiator, i.e. ribbed surface, heat transfer is greatly enhanced.

Heat exchange

The aluminum radiator heats the room in two ways:

- heat emission - in the passport of the product is indicated in watts. To calculate the total value of the parameter for the heater, you need to multiply the power of the section of the aluminum radiator 500 by their number in the battery;

- by convection.

Due to the high degree of heat transfer, radiators have low inertia. This means that they do not need to heat the coolant to a high temperature, and this, in turn, protects the boiler from wear.

Lifetime

Almost all manufacturers of aluminum radiators guarantee consumers that their products will serve faithfully for 10 to 20 years. More famous manufacturers throw another 5 years.

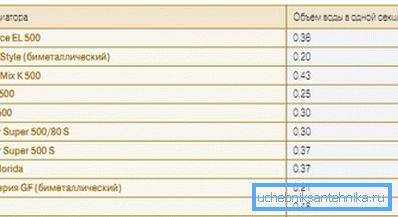

However, the device can last for much longer. It is only necessary to periodically inspect it and in time to eliminate all the flaws. Depending on the model chosen, the technical parameters of the radiators are as follows:

- length between the centers of the supply pipes or axes - 200 mm, 350 mm, and 500 mm;

- system pressure - 6-16 bar;

- heat output or power of aluminum radiators 500 based on 1 section - 82 W-212 W;

- section weight - 1 kg-1.47 kg;

- section capacity - 250 ml-460 ml;

- the highest degree of heating is 110 ° C;

- warranty period - up to 15 years.

The most famous manufacturers

The rating of bimetallic radiators for heating is 500 by 80 as well as the aluminum radiators are constantly changing, today the most in demand are:

- Faral - from Italy to Russia, this manufacturer supplies two types of radiators, one of which is Faral Green HP, and the other - Faral Trio HP. The distance between the collectors is 500 and 300 mm. When assembled, the number of radiator sections varies from 3 to 16. At the same time, they are fixed among themselves with the help of nipples.

- Kalidor - these batteries are produced, like the previous ones, in Italy, the use of the latest technologies has significantly improved the technical parameters of these products. Radiators have high heat dissipation and corrosion resistance. Paint is applied in a special way, which gives it extra strength.

- Rovall - a special popularity in Russia acquired several models of this manufacturer. This is due to the wide choice of colors and the strength of the design of radiators.

Conclusion

Any heater has its own technical parameters, in this case we are talking about an aluminum radiator with a distance between the centers of the collectors of 500 mm.

The industry offers customers various sizes of heaters so that they can be installed with their own hands as comfortably as possible and in the chosen location. The video in this article will allow you to find additional information on the above topic.