Aluminum radiators. advantages and disadvantages. cast,

Aluminum radiators appeared on sale relatively recently, but their popularity is growing every year due to a number of advantages. However, it should be noted that this group of products has certain disadvantages, and in order to understand the issue in detail, they should also be described in detail. This review will help you determine whether aluminum products are suitable for you and how to properly operate such systems.

The advantages and disadvantages of radiators

Start a review should be with these factors, as they determine the popularity of the product among buyers and its relevance. As for the positive aspects, the following can be noted:

| Reasonable cost | The low price makes this option affordable for the widest range of customers, while the operating characteristics are quite high, and if certain operating conditions are observed, the design will not yield in terms of durability to many of the options |

| Light weight | A medium section weighs from one to one and a half kilograms, that is, a complete design of ten ribs weighs only 10-15 kg, this greatly simplifies loading and unloading and installation with your own hands, you do not need several assistants, as is the case with cast iron radiators |

| Low inertia | The material has a low thermal inertia, so the elements react very quickly to changes in the temperature of the coolant. This allows you to very accurately regulate the temperature in the rooms, especially if you have devices installed on each radiator |

| Attractive appearance | Products look very neat, the surface is smooth, the shape of the sections is specially designed for the best efficiency. Products are usually coated with wear-resistant, high-temperature, polyurethane-based powder paint, which preserves the brightness of the color over a long period of time. |

Note! It is impossible not to note the fact that in terms of price and quality this option is optimal, from this segment a more effective option simply does not exist.

Now consider the shortcomings of aluminum radiators:

- The main disadvantage is the demand for the quality of the coolant, the acidity in the liquid should be normal; there should be no rust and other solid particles in the composition, as they scratch the internal surfaces during the circulation process, which subsequently causes corrosion processes. The long service life of aluminum radiators is possible only when using high-quality fluid in the system.

- Do not connect structures with copper elements., as it causes an electrochemical reaction, as a result of which the material collapses very quickly and becomes unusable. Also in such systems can not be used boilers with copper heat exchangers.

- If the intersection joints were not tightened reliably, then leaks may occur in these places..

- Radiators are not resistant to water hammer, which can happen in centralized heating systems, therefore, experts recommend using this option in individual communications, and for apartments to purchase more robust bimetallic options.

Types of products

Consider the main types of aluminum radiators, on the market there are several options, each of which has its own characteristics.

Cast products

The most budget and low-cost option that is most in demand due to its low cost, you can tell the following about it:

- Aluminum radiators of this type are made as follows: first, the molten material is poured into molds and after cooling, the blanks are laid out for complete cooling.

- Further, all excess parts and flows are removed, and the neck is soldered to the element, after which the tightness of the resulting assembly is checked.

- Then the workpiece is lowered into the electroplating bath for the application of a protective anti-corrosion coating from the outer and inner side.

- After this, the products are dried and sent for painting, then the cast aluminum radiator is thoroughly dried at high temperature.

- The last section is once again checked for tightness, after which they are assembled in a design of a certain size and packaged.

Extruded options

The extrusion process is as follows:

- Initially, individual structural elements are made from sheet blanks by stamping, their edges are processed and polished.

- Further, in a special form, parts under high pressure are pressed together, the seams are additionally soldered to ensure the best reliability.

- Then the finished elements are checked for tightness, and if everything is normal, the nodes are sent for painting, after which they are assembled into structures of a certain number of sections.

Anodized options

In fact, these are the same cast products, but there are a number of differences:

- Products are made from the best quality raw materials that meet the highest European standards.

- The shape of the sections differs due to the fact that they are not interconnected by nipples, but by clutches that are located on the outside, this makes the internal cavity smooth, which increases heat transfer and reduces the likelihood of deposits.

- Anodic oxidation is a process that allows you to change the surface structure of the material, making it several times harder and more resistant to damage and corrosion, thanks to which products can withstand pressures up to 60 Bar.

Key Product Features

Now consider what indicators have finished products, it is important when choosing a specific option for a particular room:

- Center distance is the distance between the horizontal cavities above and below. Most often, the sale presents three main options: 200, 350 and 500 mm, but if necessary you can find some non-standard options, although most often they need to be ordered, since no one keeps such products available.

Note! Remember that the actual height differs from the center distance by about 80 mm, do not miss this moment, otherwise you can get too high a radiator for a limited space.

- As for such indicators as width and depth, they are always the same and most often make up 80 mm, although the second parameter for some manufacturers may be slightly less or slightly more.

- Any instruction attached to the radiator gives two pressure values - working and pressure testing, and if everything is clear with the first option, the second should be clarified. Compression pressure refers to an indicator that occurs in the system when it is checked before the heating season, utilities pump water under pressure one and a half times higher than the worker to check the reliability and tightness of all elements.

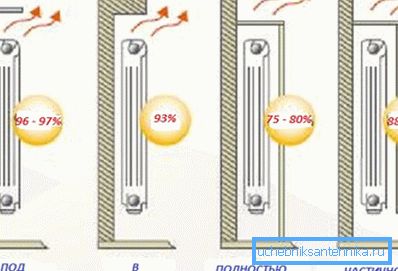

- With regard to the rate of heat output, the aluminum radiator is one of the most efficient, on average one section gives 100 to 150 watts of heat, more options may have characteristics greater than 200 watts. Keep in mind that the heat transfer depends on the installation option, in the diagram below it is shown clearly.

- As for the service life, aluminum radiators have a resource ranging from 10 to 20 years. Although many modern options can boast even more solid figures - up to 30 years or even more, it all depends on the mode of production.

Recommendations for choosing the best option

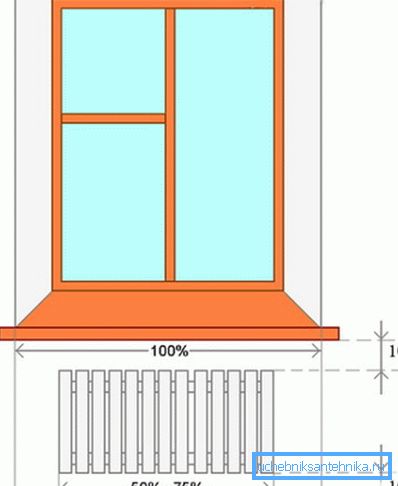

When carrying out calculations, we recommend first to make a plan for the location of all radiators, it is best to place them under the windows in order to create a heat curtain in the openings and thereby reduce heat loss.

It is also necessary to determine the height of the elements, here it is worth remembering simple rules: the distance from the floor to the radiator should be at least 100 mm, the same gap should be present between the radiator and the sill, there should be an indent of 30-50 mm from the wall.

As for the calculation of the number of sections, this information is fully presented in one of the reviews on this resource, use it to carry out this type of work correctly and accurately. It should only be noted that the maximum width of the radiator should not be more than 16 ribs, and it is better to put two batteries of 8 each at all, this will give the best effect.

If you like unusual solutions, then you can purchase designer radiators made of aluminum, they differ in their unusual appearance and configuration, but they are also much more expensive than standard products.

Conclusion

Aluminum radiators are an excellent solution for a private house, but in high-rise buildings you can use this option if you choose more reliable modifications. The video in this article will tell you more about the product group we are considering.