Automatic solid fuel boilers: how to heat a house with

Climatic equipment operating on wood or coal can heat a house of any size efficiently and inexpensively, especially if there is no gas or a powerful power line in your village. However, few want to go to the boiler room three or four times a day and load the fuel necessary to maintain the twenty-four-hour burning process. That is why so popular automatic solid fuel boilers, which will be discussed below.

Features of solid fuel boilers with automatics

Equipment types

The heating unit working on firewood is an excellent substitute for gas, electric and liquid-fuel climatic devices. It can be installed in any home and it can be heated efficiently throughout the winter. It is enough to stock up with the necessary amount of fuel: wood, coal or pellets, the price of which is quite affordable for everyone.

However, the wide distribution of this equipment is hampered by one big minus: you have to do it yourself, constantly load energy into the combustion chamber. To do this several times a day, including at night, visit the boiler room, which, as a rule, is located in a separate room.

This disadvantage is completely devoid of automatic solid fuel boiler. Specially designed automatons pick up fuel from a pre-filled bunker and feed it into the combustion chamber. All you have to do is to replenish the storage and periodically remove the waste accumulated in the ash pan.

Automatic heating boilers for solid fuels are of three main types:

- Traditional. These are classic units whose circuitry has been known since time immemorial. Can work on wood, coal, coke, pellets, fuel briquettes for heating and so on. Automation for solid fuel boilers of classical design is not provided. All management is carried out manually:

- air volume is regulated by a gate valve;

- temperature conditions in the house are set by fittings mounted on the boiler pipes;

- The amount of fuel put in depends on the performance and setting of the auger feed line.

- Combined. Such boilers are often equipped with several furnaces, in which different types of fuel are burned. Automation of solid fuel boilers independently selects operating modes to achieve the most complete combustion of fuel and efficient heating of the circulating coolant. The instruction manual for some models of the climate equipment in question allows the use of several types of fuel only if you manually upgrade the burner. Such units cannot be called fully automatic.

- Pyrolysis. These are the most modern, effective, but rather expensive models of heating equipment. Their control system is built almost the same as automatic for gas heating boilers. After setting up all the modes, you will not need to interfere with the operation of the equipment, at least for a month. Pyrolysis boilers have two combustion chambers. In the upper firebox, pyrolysis gases are emitted from a specially smoldering wood, which are then burned down at the bottom. This achieves a very high efficiency - up to 90%. The big lack of equipment is energy dependence. Pyrolysis solid fuel boiler with automatics cannot function in case of a power line accident.

Tip! In order not to freeze in the winter in case of power outages, it is recommended to equip the boiler room with a battery uninterruptible power supply or a diesel electric generator. Then the climate system of your home will be completely autonomous.

When purchasing a solid fuel boiler in the store, including an automatic one, pay attention to the following characteristics:

- power unit - varies from 10 to 250 kW, is selected based on the area of heated premises;

- the type of fuel used - these can be firewood, coal, coke, pellets, torch, peat, sawdust, and so on; the choice depends on the availability of the listed types of fuel in your region and its price.

The principle of operation of the fuel supply line

Automation for heating boilers, which is responsible for supplying a selected type of fuel to the furnace, can be built into the heating unit itself or be supplied and installed separately.

The second variant is most often used, since it is more flexible. You can choose the model of heating equipment you need in terms of power and other parameters, without paying attention to devices for automatic fuel loading.

But the separate acquisition of the boiler and the energy supply device has one drawback: it is necessary to install all the units in the boiler room very carefully. The slightest discrepancy of the instruction can lead not only to the breakage of the auger or boiler, but also to the ignition of the boiler room. On the other hand, correct installation is a guarantee of long and trouble-free operation of the climatic equipment.

Tip! To be sure of the quality of the installation of devices, it is desirable to entrust the implementation of this procedure to specialists. Although the cost of their services will have to be paid separately, they guarantee the correctness of the work, which will give you confidence in safety.

Having established the bunker of automatic giving, it is necessary to fill it with fuel. Naturally, ordinary logs will not work here.

It is necessary to use energy in the form of individual granules. To get them today is not a problem. They are sold in all specialized outlets at an affordable price.

Moreover, many modern models of automatic feeders can be loaded with wood waste: chips, splinter, sawdust, and so on. Some are able to transport even medium-sized pieces of wood.

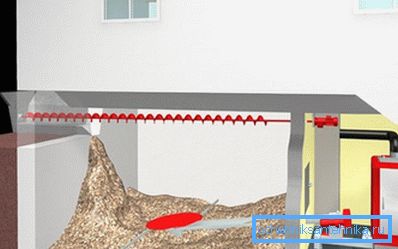

Structurally, the automatic loading bunker consists of the following elements:

- tanks in which fuel is stored;

- a screw that feeds wood or its waste into the combustion chamber;

- electric motor driving the auger.

Additional devices for automating the operation of a solid fuel boiler

In addition to mechanical fuel supply, pyrolysis boilers are equipped with other devices that increase the ergonomics of their operation.

These include:

- Climate control systems in the premises. Special sensors read the temperature readings on the street and inside the house, and then on the basis of these data regulate the flow rate of the fuel and the air flow into the combustion chamber. This increases or decreases the degree of heating of the coolant and as a result, the temperature in the rooms.

- Ignition of fuel in the combustion chamber. Pyrolysis boilers, unlike their fellow classical design, can independently initiate the process of burning fuel in the combustion chamber. This makes it easier to start the heating system after the onset of cold weather. Whatever it was, but the automation of cleaning the ash pan from the accumulated waste there has not yet been invented. Therefore, from time to time you will have to free this camera from the ashes with a shovel and poker. No worries. Pyrolysis boiler burns fuel into the smallest grits, so this procedure will need to be carried out no more than once a week.

The most modern models are equipped with electronics, allowing them to control the modes of operation at a distance or change certain parameters depending on the time of day, day of the week, and so on.

Safety rules for the operation of an automatic boiler

Despite the fact that all modern models of heating equipment, including solid fuel boilers, are equipped with various automatic devices that maximize the safety of their operation, some measures in this direction should be taken by the cottage owner.

In particular, the following requirements are imposed on the installation site:

- The boiler can be installed only in a specially designated room that meets fire safety standards.

- The room should be equipped with a productive supply and exhaust ventilation, preferably a forced type (with electric fan).

- The boiler must be mounted on a specially equipped durable pedestal or foundation made of concrete.

- The boiler room should be equipped with a chimney to remove the combustion products.

Conclusion

Automatic solid fuel boiler - a great alternative to a gas or electric heater. A special loading mechanism allows to significantly improve the ergonomics of its use, and the innovative pyrolysis method of burning fuel makes it possible to use energy carriers more economically.

It is only necessary to choose the right fuel for the installed unit. This will help you video posted below.