Autonomous heating systems: exploring heat sources

The topic of this article is autonomous heating systems. We will try to find out what they are and what can be used as a source of thermal energy for them. In addition, we have to conduct a comparative analysis of the cost-effectiveness and ease of use of certain solutions.

Classification

To begin with, on what grounds can be classified independent heating.

According to the source of heat energy.

Here is a list of possible solutions:

- Gas (main and liquefied gas - in gas holders and cylinders).

- Coal.

- Firewood.

- Pellets (granulated wood waste).

- Diesel fuel.

- Electricity.

According to the method of heat transfer from the boiler to the peripheral premises.

There are only two of them.

- Water heating is most popular due to the high heat capacity of the water.

Note: along with water, coolants with a lower crystallization temperature can be used, allowing you not to be afraid of defrosting when stopping heating and circulation. In the bulk it is a mixture of water with ethylene and propylene glycol.

- Air heating is often combined with ventilation.. Air heating is used to heat the room.

Efficiency

Let's compare the costs that each of these heat sources promises to the owner.

| Heat source | Price kilowatt-hour heat, rubles |

| Gas (main) | 0.7 |

| Firewood | 1.1 |

| Coal | 1,3 |

| Pellets | 1.4 |

| Gas (gas tank) | 1.8 |

| Gas (cylinders) | 2.8 |

| Diesel fuel | 3.2 |

| Electricity | 3.6 |

Nuance: in some regions of the country specific prices may vary. However, their ratio will continue.

A special case

The study of operating costs brought us an unexpected discovery: in the 21st century, firewood is still the cheapest source of heat in the absence of main gas. Not only that: for residents of rural areas, the cost of them can be altogether reduced to zero - picking a dead wood and pruning trees in the area means to cover the need for fuel. But the most seemingly progressive source of heat - electricity - was at the bottom of the list.

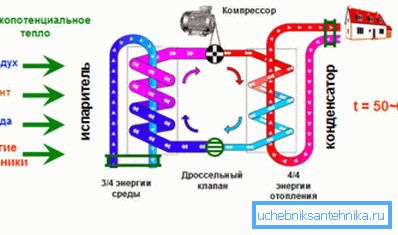

However, this alignment will be true only for devices of direct heating, which convert kilowatts of electrical power to kilowatt of heat power. For a heat pump, the picture is fundamentally different: its device allows for 2 to 5 kilowatt-hours of heat for every kilowatt-hour of electricity consumed.

Due to what?

The secret is simple: energy is spent not on generating heat, but on moving it from a low-potential source to a high-potential source. Simply put, the device of the heat pump allows you to cool the already cold environment even more and heat the house with the resulting heat.

How is this effect achieved?

- The volatile refrigerant is compressed by the compressor and goes into the liquid phase with a large amount of heat.

- This heat is given to the heat exchanger and is used to heat the room.

- After the heat exchanger, the coolant that has lost heat passes through the expansion valve and turns into a gaseous state, cooling sharply during expansion.

- Then it goes to the second heat exchanger. Since it is cooled to a temperature lower than that of the environment during the passage of the refrigerant, a constant heat flow arises: the refrigerant heats up and, when heated, returns to the compressor for a repeated cycle.

Heat pumps with the highest COP (coefficient of performance, parameter that denotes the ratio of heat and electric power of the pump in heating mode) reduce the cost per kilowatt-hour of heat to 3.6 / 5 = 0.72 rubles, which practically equalizes their profitability with gas equipment and leaves far behind competing solutions.

By the way: for most heat pumps, the average COP during the season is more realistic, equal to 3 - 3.5.

The convenience of use

In terms of economy, the list of important qualities for the consumer does not end. At least one more parameter is not less important - usability.

And from this point of view, a completely different table of ranks is being built.

- All electrical equipment (both direct heating devices and heat pumps) are completely autonomous and do not require care or maintenance. For obvious reasons, the removal of combustion products is also useless.

- Gas and solar heating boilers are also capable of long-term autonomous operation. However, in terms of ease of use, they are somewhat inferior to electrical appliances: they all require the removal of combustion products; for a solarium, the need is added to equip for it a capacity of several cubes and to tolerate the noise of the burner, which is slightly inferior to the roar of an airplane during takeoff.

The use of bottled gas requires additional attention: the balloon will have to be changed from once a day to a couple of times a week.

- The battery life of a pellet boiler can reach a week due to the automated supply of fuel from the bunker. However, like all solid-fuel devices, it needs periodic cleaning of the ash pan.

- Finally, wood and coal boilers and stoves require constant attention: they have to be fired several times a day.

Water heating

Let's take a closer look at what heat sources can use autonomous heating systems.

Gas and solar boilers

Their device is quite understandable: a gas burner heats the heat exchanger and transfers heat to the coolant circulating through it.

What else is it helpful for a potential buyer to know about gas equipment?

- Non-volatile devices are equipped with piezo-ignition and are used to ignite the main burner when the temperature of the coolant drops so-called pilot. Electric ignition boilers do not have it and due to this they provide about 20% gas savings.

Please note: electric ignition does not fit well with the instability of the electricity supply in rural areas. Partly, however, the problem is solved by installing uninterruptible power supplies that can support the boiler for 4-6 hours.

- An atmospheric burner draws indoor air and removes combustion products to the ventilation duct or chimney. A closed burner means taking air from the street and discharging the combustion products along the same coaxial (double-walled) pipe.

- Condensation boilers provide 9-11% gas savings compared to classic ones. They not only take away heat from the combustion products, but also condense them on an additional heat exchanger. By the way, the return temperature in 30C, characteristic of floor heating systems, is optimal for them; in a conventional boiler, it causes condensation to form on the heat exchanger that is not adapted for this and its early failure.

- Gas boilers are often unified with solar. There are many designs that allow you to change the type of fuel by simply replacing the burner.

Solid fuel boilers

The classic device of this type consists of a firebox with a jacket-heat exchanger, inlet and outlet nozzles, an ash pan with a blower and an uncomplicated automation system. In the event of overheating of the coolant, the simplest mechanical thermostat covers the blower, limiting the access of air and reducing the thermal power of the device.

This scheme is simple, exceptionally fault tolerant, but it has a couple of serious flaws:

- Loading the firebox is required every 2-4 hours.

- Restriction of air flow leads to a catastrophic drop in efficiency due to the fact that products of incomplete combustion evaporate through the chimney. With a limited access of oxygen, firewood and coal form carbon monoxide (by the way, toxic) and volatile hydrocarbons.

In an attempt to solve these problems, a couple of very curious designs were created.

Gas generator

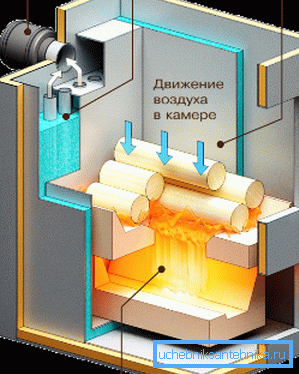

Gas generator (pyrolysis) boiler breaks the process of burning fuel into two stages.

- It smolders with a limited flow of air, burning down to the state of ash and producing pyrolysis gas - the very volatile hydrocarbons.

- Then the pyrolysis gas enters the afterburning chamber located under the main furnace, where it receives a new portion of air through the injectors. At high temperatures, this leads to an instantaneous ignition of the gas-air mixture.

What is the result?

- Flexible power control without loss of efficiency.

- Long (up to 12 hours) burning on one tab of fuel.

Top burning

Even more curious is the modification of the gas generator - the upper burning furnace. The principle of its work is reduced to the transfer of smoldering wood or coal from the bottom to the top surface of the bookmark.

How it works?

- A movable air duct is lowered into the firebox loaded and fired from above, ending with a massive disc - air distributor.

- Air inflow is provided over the entire surface of the fuel layer. It is dosed manually or automatically adjustable valve.

- The chamber above the air distributor disc is used to afterburn products of incomplete combustion. In this case, the ascending air flow completely carries ash, which can prevent decay.

The maximum battery life shown by the upper combustion boiler from the Lithuanian company Stropuva is 31 hours.

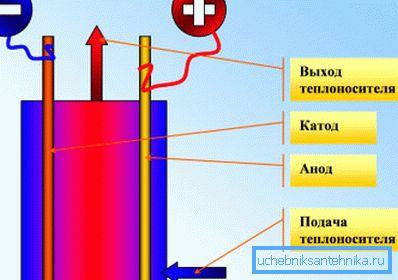

Electric boilers

Direct heating appliances are also divided into several categories. Tenovye use for heating tubular heaters placed in a flow tank. Power is regulated in steps. The design is sufficiently fault tolerant, inexpensive and does not have any serious flaws, except for the low efficiency typical of all devices for direct heating.

Electrode boilers use alternating current passing directly through the water. Their main advantage is compactness. Disadvantages - the gradual dissolution of the electrodes and the ability to work only in water with a certain mineral-salt composition.

An induction boiler is a ferromagnetic core and a winding placed in a dielectric tube that excites eddy currents heating the metal in it. The main advantage of an induction boiler is its phenomenal resiliency and unlimited service life: there are simply no parts that wear over time.

Important: any claims that some kind of electric boiler is more economical than competing solutions are the first lie. Any device direct heating turns into heat 100% of the spent electricity. Even if, due to design features, thermal energy is not completely transferred to the coolant, but partially dispersed in the air, it still heats your home.

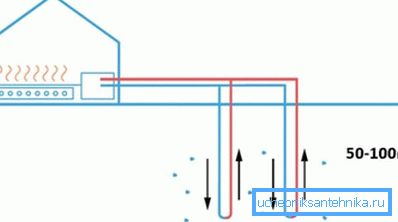

Heat pumps

They can use several types of low-grade heat sources.

Geothermal

Heat exchangers are placed below the freezing level and take heat energy from the ground. The main problem with these pumps is costly installation.

There are two possible options.

- Probes descend into vertical wells 30 to 100 meters deep.

- The collector is laid horizontally.

The second option is attractive because the trench under the horizontal collector can be dug with your own hands, which significantly reduces installation costs. However, the area under the sewer should be about three times the heated one; however, it cannot be used for planting - the plants will not tolerate the temperature regime of the collector.

Water

They can be implemented in two ways:

- The collector is placed on the bottom of the ice-free reservoir.

- Two wells are used for heat exchange - flow rate and drainage. The heat that has given off is drained back into the aquifer.

Aerial

They can be ideal for warm climates. The low cost of the solution, cheap and easy installation make them a very attractive source of heat in the absence of main gas.

It is worth considering, however, a couple of subtleties.

- Even the best devices of this type retain their performance at temperatures of outside air up to -25 ° C.

- As the temperature drops, the COP of the instrument drops. If at +10 it is equal to five, then at -25С it will decrease to two.

An important point that is relevant for all types of heat pumps: the lower the coolant temperature, the smaller the delta between it and the environment, which means the higher the COP of the device. That is why with heat pumps of all types, radiators with a large number of sections are used, and the coolant temperature does not rise above + 45С.

Air heating

Gas, solar and solid fuel boilers air heating completely duplicate the features of their counterparts, designed to heat water. Separately it is necessary to allocate only a couple of designs.

Buleryan

Under this name, taken from one of the first manufacturers, hides convection oven-gas generator. Its main feature is that the firebox is surrounded by open bottom and top steel pipes of large diameter, in which stable convection currents arise during heating. The curvilinearity of the pipes contributes to the effective mixing of the air in the room.

Note: heated air can be diluted with a duct system. Conventional duct fans can be used to force it.

Inverter air conditioner

Any air conditioner is a special case of an air-to-air heat pump. It is the inverter that differs in that it uses AC-to-DC conversion, which allows flexible control of the compressor power. When air is heated to the desired temperature, the compressor does not stop, but reduces speed.

A side effect of the fact that the compressor is constantly in operation is the ability of the inverter to perform its functions at low (up to -25 ° C) temperatures. Actually, many models are positioned by manufacturers as household heat pumps.

Heating by inverters is undoubtedly the best solution in regions where winter temperatures do not fall below -10 - -20 degrees. So that the instruction for choosing a heating scheme is not unfounded, the author will share his own experience of using an inverter air conditioner for heating an attic floor last winter.

| Parameter | Value |

| Air conditioner model | Cooper&Hunter CH-S12FTXN |

| Cost with installation | 27,000 rubles |

| Thermal power in heating mode | 4.12 kW |

| COP | 4.2 |

| Power consumption in heating mode | 0.22 - 1.55 |

| Heated area | 60 m2 |

| Maintained temperature | +22C |

| Average temperature of the month | +2C |

| Lower peak temperature | -21C |

| The actual electricity consumption of air conditioning for the month | 400 KWh |

| Location | Sevastopol, Crimea |

Conclusion

We hope that our miniature review will help the reader to choose the optimal solution for his conditions. Additional information about what can be an autonomous heating system, will offer an attached video. Successes!