Bimetal radiators. specifications. calculation, mounting,

What are bimetallic radiators and how are they arranged? When is their choice justified? What should be the binding of the device? What pipes to connect this battery? Let's figure it out.

What it is

So, a bimetallic radiator: what is it? The main characteristic of any heating device is its heat transfer, the amount of heat it is able to transfer from the coolant to the air in the room.

Heat transfer is determined by two factors:

- Radiator surface temperature;

- Its area.

Increasing the heat exchange surface area is possible in two ways:

- By increasing the internal volume of the section. There are a number of limiting factors here - the weight of the section (and, accordingly, the load on the fasteners) and the dimensions of the radiator;

- Due to the formation of advanced fins.

However: the main condition for high heat transfer of the instrument with a large area of fins is the high thermal conductivity of the metal from which it is made. Otherwise, the cold ribs simply will not remove heat from the internal channels of the sections.

In the mass production of heating devices, three relatively inexpensive metals — steel, cast iron, and aluminum — have long been widely used. The thermal conductivity of aluminum is four times greater than that of the first two metals:

| Metal | Heat conductivity, W * m / K |

| Steel | 47 |

| Cast iron | 50 |

| Aluminum | 200 |

It would seem that the choice is obvious: the high thermal conductivity of aluminum allows you to create a compact and lightweight device with the highest heat transfer. And this is true, but the trouble is that the low mechanical strength of the metal limits its use in central heating kennels.

The reason is a high probability of water hammer. It is necessary to close the valve or the valve abruptly - and the inertia of practically incompressible water will create a shock wave, the pressure at the front of which will reach 20-25 kgf / cm with the strength of aluminum batteries not more than 16.

So what is a bimetallic radiator that has aluminum heat dissipation and steel pipe strength? It is just a core of corrosion-resistant steel, on the surface of which an aluminum fins are formed by casting. The use of two metals with different properties allows you to get rid of the weak points of each of them, creating a design that is ideally suited for the CO systems.

Specifications

The strength and heat transfer (and, of course, the price) of the bimetallic section depends on several factors:

- The shape and size of the core. It can only strengthen the vertical channels of the section or, which will provide much more resistance to hydrostatic pressure, combine the vertical channels with collectors;

- Core metal thickness. The section strength depends on it;

- The area and thickness of the fins;

Note: the thicker the ribs with a fixed surface area, the more heat they spend, the more uniform the surface heating.

- The presence or absence of nipple connections between sections. Thread, even if steel, will always be the weak point of the device.

As a sample, we present the characteristics of one of the best devices in its class - the domestic Rifar Monolith.

| Parameter | Value |

| Operating pressure | 100 kgf / cm (tests are carried out with a pressure of 150 kgf / cm2) |

| Working temperature | 150 С |

| Heat transfer to conditional section | 205 watts |

It is curious: in the bulk, domestic manufacturers produce bimetallic radiators according to GOST 31311-2005. However, there are no regulatory requirements for bimetallic instruments; only the minimum allowable working pressure of 6 kgf / cm2 is specified.

The minimum service life of bimetallic radiators of heating is estimated at 25 years.

Installation

Payment

So, with the choice we have decided. How to calculate bimetallic heating radiators on the parameters of your apartment?

With the standard (2.5 - 2.7 meters) ceiling height, you can use the simplest calculation scheme:

- 100 watts of heat are taken per square meter of space;

- Depending on the climatic zone, a coefficient from 0.7 (Crimea) to 2.0 (Yakutia) is used;

- Heat transfer section is estimated at an average of 180 watts.

So, for the Moscow region, you can use the regional coefficient of 1.2; for a room with an area of 25 meters you will need 25 * 100 * 1.2 = 3000 watts of heat, which corresponds to 3000/180 = 17 (rounded) sections.

Mount

How to hang a bimetallic radiator on the wall?

- Normally, pin brackets are used for fastening, which are screwed into plastic dowels;

- Instead, you can use pieces of smooth steel reinforcement with a diameter of 10-12 mm, hammered into the pre-drilled holes of a slightly smaller diameter.

Binding

What accessories for bimetallic radiators will be needed when installing them by hand?

- Set of radiator plugs (4 pieces, external thread DU25). The diameter of the internal thread of the bushing plugs is determined by the number of sections of the device: if there are less than 10, the liner with a nominal diameter of DN15 is sufficient;

- Throttle or thermal head and ball valve with American for connecting to traffic jams. The throttle will allow you to adjust the heat transfer device manually, thermal head - automatically, depending on the temperature of the air in the room;

- At the top of the apartment’s riser, the radiator will have to be equipped with a Mayevsky crane for air bleeding.

What pipes to use for connection? Preferably - corrugated stainless.

What is the reason for this instruction?

- They have high tensile strength;

Important: Plastic or metal-plastic pipes will always be the weak link: what's the point in a radiator that can withstand a water hammer with a peak pressure of 40 atmospheres if the pipes burst already at 20?

- They bend with a minimum radius and do not require precise fit sizes;

- They are mounted with compression fittings using a pair of adjustable wrenches.

Build Tips

Radiator plugs are sealed with paronitic or silicone gaskets - the same ones that are used to build up the bimetallic radiator with additional sections.

Other connections are rewound with thread sealant Tangit Unilok or flax with paint.

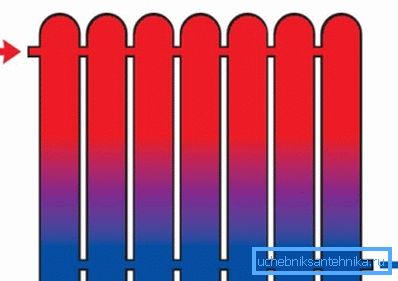

With a large radiator length (10 sections), use a diagonal connection rather than a side connection. Then you don’t have to guess why bimetallic radiators do not heat along their entire length: with lateral connections, the coolant will circulate only through the first sections from the liner.

Choice of the heat carrier

How to fill bimetallic radiators in those rare cases when they are used in an autonomous heating circuit?

In most cases, ordinary water is used as a coolant. Besides the fact that the cores of the bimetallic sections are sufficiently resistant to corrosion, their contact with atmospheric oxygen is completely excluded when the circuit is filled with water. Meanwhile, in an oxygen-free environment, the appearance of rust is impossible.

In those cases when it is possible to stop the heating circuit at low temperatures, it is practiced to refill bimetallic radiators with non-freezing heat transfer fluids:

- Aqueous solution of propylene glycol;

- Tosol;

- Transformer oil.

Conclusion

In conclusion, we recall once again: bimetallic batteries will be the best choice in central heating systems. The video in this article will help the reader to learn more about the characteristics and features of installation of these devices. Successes!