Biofuel at home: how to cook cheap fuel yourself

Man learned to receive fuel from waste back in ancient times. For example, homemade biofuels from cattle were made by people involved in cattle breeding. And today, savvy homeowners manage to provide themselves with virtually free energy. It all depends on the availability of raw materials nearby.

Fuel production options

Here are the main types of raw materials that it is possible to use for the production of a useful product for the economy.

- Waste crops and wild plants.

- Manure.

- Rape, cane, corn, soy.

- Wood.

Note! The advantages of the resulting fuel are also complemented by the absence of harmful substances emitted in large quantities when burning peat, coal or gas. The resource does not create a greenhouse effect, which is very important in an ecological sense.

Advantages of a biological product

Even the ancient Chinese have learned to benefit from foliage, litter and grain crops. The retarded technologies take on a second life today.

Now industrial products at a cost close to the price of gasoline. But the production of biofuels at home will significantly reduce costs. Especially, if you get the original raw materials for free.

Manure use

Ideal for livestock owners or farmers. What previously had to get rid of, can bring considerable benefits. Horse manure is considered the most practical. But cow, rabbit, avian, goat or sheep waste will also serve well. (See also the article Solar collectors for home heating: features.)

Manure-based mixtures

- Dung horse + peat or straw.

- Adding household garbage in proportions 1/1.

- Mixing 3 parts flax fires to 7 parts of the litter.

- A mixture of horse and cow product in equal proportions.

- Waste of a cow (7 parts) + sawdust (3 parts).

- Horse product (7 parts) + foliage (3 parts).

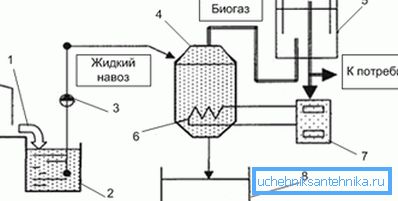

High-quality biofuel from manure at home is obtained in the fermentation process. In a specially equipped bunker, a chemical reaction occurs, as a result of which moisture and biological gas is released.

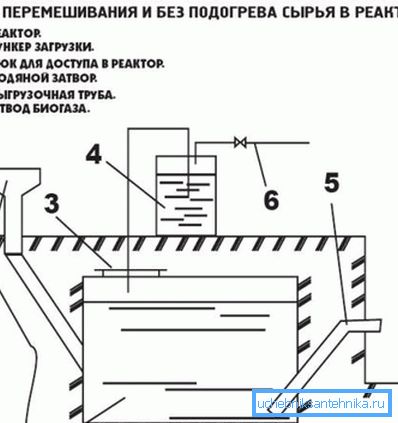

Manufacturing installation

Based on the technology invented and tested by experience by many craftsmen.

- Digging a hole, the size of which depends on the amount of raw materials.

- It is advisable to insert reinforced concrete rings into it. Such hoops are usually used for the construction of wells.

- A heavy metal lid is made or sized. At the same time mount the discharge pipe.

- The pit is filled with organic matter, closed and left for 5-7 days.

Note! If the finished gas is planned to be used for a gas stove or boiler, the instruction recommends installing burner adjustment. Since biogas contains less methane, an additional supply of oxygen that improves combustion is needed.

Gas recovery from waste mixture

As an option, we offer an equally effective technology.

It uses various additives.

- Mix 2 tons of manure and 4 tons of any plant waste (leaves, grass, hay).

- Moisten the mixture with water to a level of 75%.

- In the tank, the slush should be heated using a coil to about +35 ?.

- In the process of heating, isolate the components from air intake, ensuring tightness.

- Next, the heating is stopped, after which the raw material, due to a chemical reaction, will continue to heat up independently.

- The released gas is discharged through the vent pipes and is used for its intended purpose.

What is a bio-based gas?

To understand the composition, it is not necessary to be a professional chemist.

Enough school knowledge, remember that for your own good will not interfere.

- Carbon Dioxide (CO2).

- Methane (CH4).

- Hydrogen sulfide (H2S).

- Other impurities.

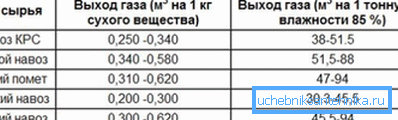

It should be noted that from 1 kg of manure or a mixture with it you can get 0.5 liters of gas.

Independent production of briquettes

Not everyone has their own or nearby farm. This is not a reason to give up; perhaps there is a sawmill or a woodworking company very close by. You will need sawdust, wood chips, bark and other waste.

Then the production of biofuels at home - the task is easily implemented.

- Find a source of raw materials and arrange for its supply.

- For the production you need a special press. It can be purchased at the store or ordered online.

- Fans of doing everything with their own hands may well make a pressing unit, guided by simple drawings.

- Having adjusted production, you will be able to provide yourself with high-quality fuel. If you wish, you can expand the scale and make products also for sale.

Charcoal Making

Everyone knows that coal is mined in mines or quarries. Energy carrier practical, used both in everyday life and in industry.

Many bought it for picnics with barbecue, someone buys for a full house heating. But the price, unfortunately, bites. But coal is easy to do yourself, even in several ways.

Creation of coal in the pit

- Choose a place where there is accumulation of dry wood, or there is a dead tree that has become obsolete.

- Dig a hole half a meter deep and just under a meter in diameter.

- Tamp the bottom, clean the nearby area of dry grass and brushwood.

Note! In connection with the increasing incidence of forest fires should be extremely cautious. Do not implement this idea where bonding is prohibited.

- At the bottom, make a fire out of brushwood and bark. Give it how to inflame.

- Gradually lay thick firewood, making sure that they are properly caught in the fire.

- Lightly stir the block with a pole, not letting the individual go out.

- For high-quality burning, it takes 3-4 hours, then the coals are covered with foliage, moss and filled with soil.

- Land should be compacted and the product left to ripen for two days.

- After the period of time, the layer of earth and leaves is removed, the coals are sieved and put into bags.

- If the next bookmark of firewood is not planned, the pit should be carefully filled and laid on top of the fertile layer and foliage.

Coal production in an iron barrel

It is better to start this process not in the forest, but in the garden.

The technology is similar to the previous method, but instead of a pit a barrel with a capacity of 200 liters is placed.

- A hole is made in the bottom of the tank and a hose from a vacuum cleaner is connected. It is necessary for the supply of air that supports combustion.

- Chumps are stacked on the fire of their thin branches and air is forced.

- Firewood is mixed with a pole or piece of reinforcement.

- After burning the barrel, it is recommended to close hermetically and leave the raw material to cool for two or three days.

Conclusion

Today you have learned how to make biofuel at home using the simplest and most popular methods. It is not difficult, as it may seem. Having decided, you will provide yourself with practically free and constant source of heat. Watching the video in this article, you will learn to benefit from all that is at hand.