Biofuel for fireplaces: eco-friendly and economical heating

Fireplaces on biofuel, so popular lately, are, rather, not so much heating devices, as design objects. No, they warm it, and quite well, but still it is better to use a more “solid” construction as the main source of heat.

Below we describe the main features of such devices, and also give a number of recommendations for their independent production, as well as the production of fuel for their work.

Main characteristics

Features of biofireplaces

If it is very simple to say, then fireplaces with biofuel are big spirit stoves:

- At the bottom of the device is a reservoir, into which a special combustible mixture is poured.. Most often for this purpose ethyl alcohol (bioethanol) is used, which burns quite well in the air without additional supply of oxygen and almost does not give smoke or soot.

Note! Ethanol burns with a practically colorless flame, therefore, for more spectacular fiery tongues, various components are added to it. The most popular is high-octane refined gasoline, which gives the flame a rich orange color.

- On top of the tank is a grill that restricts the spread of the flame..

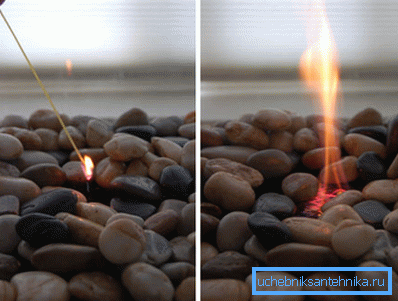

- Refractory stones or ceramic products are laid on top, imitating firewood by their shape and color..

- To protect the room from fire and to ensure uniform distribution of heat, refractory glass screens are installed around the perimeter..

In principle, such a simple design, on the one hand, provides high reliability, and on the other, it provides an opportunity for designer self-expression. And indeed, many modifications of such fireplaces can be found on the market today, and their price depends both on the volume (and hence on productivity) and on the materials used for decorating.

Advantages to use

The fireplace with biofuel has a number of positive qualities:

- First, in the process of burning practically no toxic substances are emitted, and the usual tiny amount of smoke can easily be removed by a conventional ventilation hood.

- Secondly, burning alcohol gives an even saturated heat (albeit in a limited area), so it is very nice to sit by such a fire.

- Thirdly, the hearth itself, and biofuel for biofireplaces can be made independently, and used as needed.

Note! In the manufacture and operation of the system must adhere to safety regulations. Let it be a decorative object, but still there is open fire in it, which you should not joke with.

Making biofuels yourself

Cooking fuel mixture

A biofuel fireplace is pretty easy to do with your own hands. To do this, we take a small volume refractory container, install it in a metal case and close it with a grill. On the lattice we place either pebbles resistant to high temperatures or ceramic products.

The main secret is the composition of the most flammable liquid.

As a rule, for refueling fireplaces use:

- 20 parts ethanol (about 90%).

- 1-2 parts of refined gasoline.

Tip! It is better to prepare the mixture immediately before pouring, since during prolonged storage the mixed components are stratified.

Ethanol should be taken specifically for this purpose - it is sold in specialized stores. Also, the instruction allows the use of strong moonshine, but in this case it is better to expose the liquid to additional cleaning, passing it through a carbon filter. Otherwise, when burning fusel oils, quite thick smoke and unpleasant smell may appear.

Bioethanol production

If you are familiar with the home brewing technology, then questions about how to get fuel for biofireplaces in sufficient quantities should not arise.

If you have not previously encountered this technique, then we will describe it at least in general terms:

- Practically all materials containing starch or sugar can be used as raw materials. Most often used for this purpose food waste - non-conforming grains, potatoes, etc.

Note! There is also the technology of making bioethanol from gas, which is formed during the natural fermentation of manure, but its implementation requires sophisticated technological equipment, which will have to be bought. On the other hand, if biofuel is used as the main material for heating, the costs will pay off in about two heating seasons.

- Raw materials for the production of fuel alcohol is crushed, mixed with water and subjected to fermentation.

- During the fermentation process, the yeast processes glucose contained in the liquid mass into ethyl alcohol and carbon dioxide.

- Then the ethanol is removed from the solution by distillation.

- The resulting material is dehydrated to increase the alcohol content and, accordingly, to make the fuel more combustible.

- At the final stage of the fuel, we try to remove all impurities that, when burned, will produce an unpleasant odor and soot.

Of course, at first it is necessary to implement the technology under the guidance of an experienced specialist, or to purchase a ready distillation unit. Over time, having mastered the technique, we will be able to produce the necessary amounts of fuel for the operation of our fireplace. (See also the article Fireplace chimney: features.)

Conclusion

It is somewhat more difficult to get biofuel for a fireplace than to make a fire itself. That is why we recommend to take up this matter only if you plan to actively use the installation specifically for local heating. If not, then the high-purity technical alcohol purchased at the store will be enough for you.

The video posted in this article contains a number of additional information that will definitely be useful to anyone who is interested in this topic.