Boilers for water heating on solid fuels: features, piping,

What are the solid fuel boilers for water heating? What are their advantages over products using other fuels? Do they have serious flaws? How to connect the boiler to the heating circuit? Let's try to find the answers.

Device

Modern solid-fuel water boilers are steel or cast-iron firebox with a water jacket-heat exchanger connected to the heating system. After the kindling, heating of the heat carrier begins and convection processes in it: warm water rises to the upper part of the shirt and then - up the heating circuit; cold, accordingly, goes down.

With a small length of filling and its correct configuration, the difference in density between warm and cold water is quite enough to ensure stable circulation through heating devices. More often, however, circulation pumps for heating systems are used to increase the rate of circulation and equalize the temperatures of radiators.

Almost all modern products, including solid fuel boilers of Russian origin, are equipped with the simplest automatic equipment - a thermostat that covers the blower when the coolant is overheated. This limits the access of oxygen to the furnace and reduces the thermal power of the system.

However: in boilers of traditional construction, the efficiency also drops. Combustion with a lack of oxygen increases the concentration of products of incomplete combustion: the fuel literally flies into the pipe.

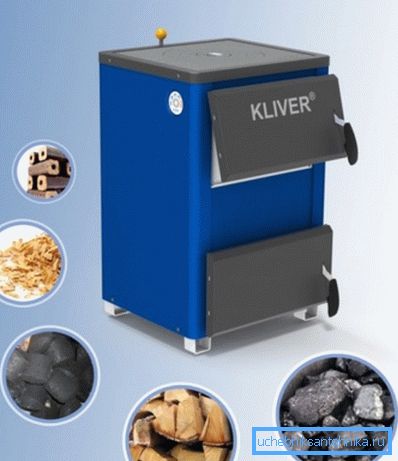

What solid fuel boilers can use as fuel?

- Firewood.

- Coal.

- Pellets (pellets pressed from wood waste).

- Peat briquettes.

In practice, they often combine two functions - they heat the house and allow them to get rid of combustible debris.

Comparison with alternatives

How does the functionality and efficiency of the products we are discussing relate to those of alternative solutions?

pros

The main and, in fact, the only convincing argument in favor of solid fuel heating equipment is the price of a kilowatt-hour of heat, second only to main gas. Not to be unfounded, we give average values for different types of fuel.

| Fuel | The cost of a kilowatt-hour of heat, rubles |

| Main gas | 0.7 |

| Firewood | 1.1 |

| Coal | 1,3 |

| Pellets | 1.4 |

| Liquefied gas from a gasholder | 1.8 |

| Liquefied gas from cylinders | 2.8 |

| Diesel fuel | 3.2 |

| Electricity | 3.6 |

Note: in rural areas, firewood often does not have to be paid in principle. Periodical collection of deadwood is able to provide heat at no cost.

Minuses

But their list is quite significant.

- The boiler requires the removal of combustion products. At the same time, in classical designs, their temperature is high enough to seriously attend to fire safety: the chimney pipe is passed through wooden structures through a heat-insulating duct.

- Solid fuel heating inevitably means a certain amount of soot, entering the house, and associated odors.

By the way: the installation of heating equipment in a separate boiler room completely solves this problem.

- Under certain conditions, overturning of traction may occur in the chimney: combustion products start to flow into the house.. In addition to the already mentioned smells and soot, this means a very real opportunity to get poisoned with carbon monoxide.

- Finally, the main thing: a wood or coal stove needs frequent loading and cleaning.. Frequency downloads for classic boilers - no more than 4 hours; with longer pauses, a drop in temperature in the house becomes noticeable.

Special performance

Some versions of the boilers are able to varying degrees of their disadvantages.

Turbine

Installing the supply fan allows you to flexibly regulate the flow of air into the combustion zone. His work with the doors of the firebox and ash pan closed makes impossible the accumulation of products of incomplete combustion and the overturning of thrust.

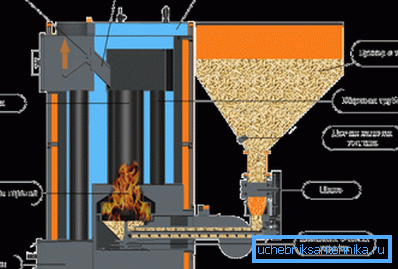

Pellet bunker

The device of automatic products on pellets (among which, by the way, solid fuel heating boilers of Russian production are quite numerous) allows metered delivery of bulk fuel for a long time. The duration of autonomous operation of such units can reach several days.

Gas generator

Gas generators, or pyrolysis hot water solid fuel boilers break the process of burning wood into two stages.

- Initially, the fuel loaded in the furnace smolders with a limited flow of air. This produces a large amount of carbon monoxide and volatile hydrocarbons.

- Products of incomplete combustion due to natural or forced thrust enter the afterburner chamber, where they mix with fresh air and ignite.

What is the result?

- The heat output of the boiler can be regulated extremely flexibly. When the afterburning chamber is located under the primary compartment, the firewood will continue to smolder even with minimal air supply.

- The power limit is no longer accompanied by a drop in the efficiency of the device. Furnace gases are burned in full.

- Finally, the frequency of fuel loading increases to 10-12 hours.

Top burning

The next step towards increasing autonomy was made by Lithuanian engineers from Stropuva. They developed water solid fuel boilers, one of which on the test bench demonstrated autonomous operation on a single load of the firebox for 31 hours.

The essence of the innovation is the transfer of the combustion process from the bottom of the furnace to the top.

- Firewood or coal is loaded into a volumetric combustion chamber.

- A movable air duct descends from above, which will sag as the fuel burns out, providing continuous access of the incoming air to its surface. The telescopic channel ends with a massive air distributor made of heat-resistant steel - with glass slab. He also separates the primary combustion and pyrolysis chambers: products of incomplete combustion are burned in the upper part of the boiler when fresh air is supplied to them.

- The smallest ash remaining in the furnace after smoldering is completely carried away through the chimney by the ascending air flow.

Binding

Instructions for connecting a solid fuel heating device to the heating system depends on its type.

Gravity system

A typical gravitational heating system in a one-story house is a single pipe Leningrad. The bottling is a ring around the whole house, in parallel with which heating devices are connected.

An accelerating collector starts from the boiler outlet nozzle: a thick filling pipe rises to a height of 3 meters. The greater the height difference between the upper point of the accelerating collector and the boiler itself, the higher the pressure created in the circuit, the faster the circulation.

An open expansion tank is installed at the top of the filling. After the collector pouring hollow, with a constant slope falls to the boiler.

A gentle slope allows you to kill two birds with one stone:

- The cooling water is drained by gravity filling, returning to the repeated heating cycle.

- Air and (when the heat exchanger is overheated) the steam is displaced into the expansion tank.

For a natural circulation heating system, the following dimensions should be followed:

| Parameter | Value |

| Filling length | No more than 40 meters |

| Filling diameter | Not less than 32 mm |

| The diameter of the supply to the radiators | Not less than 20 mm |

Forced circulation

In order to create a system with forced circulation and convection heating devices, we need a certain amount of additional equipment.

- Actually circulation pump.

- The pre-filter is installed in front of the pump.

- Cut-off pump and valve filter.

- Closed expansion tank with a volume approximately equal to 10% of the coolant volume in the circuit. It is mounted, as a rule, after about 10 diameters of filling after the pump.

- A waste valve that relieves excess pressure when overheated.

- Pressure gauge to control system pressure.

- Automatic air vent.

- Mayevsky's cranes are based on the number of radiators or jumpers between them rising above the general level of bottling.

When the length of the contour is less than 60 meters, you can do with a pipe with an inner diameter of 20 mm; with a larger size, bottling is used in size DU25.

Please note: do not confuse the control and outer diameter. Thus, the steel pipe DN20 has an outer diameter of 24-26 mm. For clearness of the contour, for obvious reasons, the internal section is important.

Research samples

Along with the import of heating equipment, the production of solid fuel boilers has long been established in the post-Soviet space.

Let's get acquainted with a pair of samples.

CWR

Under the CWR brand, heating boilers for solid fuel of Russian origin are sold from the Medved concern, which has offices in Kostroma, Moscow and Ivanovo. Their key feature is top burning; The maximum heat output of the senior in the device range, the KVR-40, allows the house to be heated up to 450 m2.

It is with the eldest in the family of KVR-40 that we will get to know each other better.

| Parameter | Value |

| Mass of fuel in one load | 100 kg |

| Maximum length of firewood | 45 cm |

| The amount of water in the boiler | 58 l |

| Water flow through the heat exchanger | 1 m3 / hour |

| Work on one tab | Up to 20 hours |

| Operating pressure | Up to 2.5 kgf / cm2 |

Tis uni

The product called Tis Uni 25 in our miniature review presents solid fuel boilers of Belarusian production. Our hero is a pyrolysis boiler with a heat output of up to 30 kilowatts.

| Parameter | Value |

| Firebox volume | 118 l |

| Duration of work on one tab | 6 h |

| Efficiency | 82% |

| Net weight | 335 kg |

| Dimensions | 140x59x70 cm |

| Heated area | Up to 290 m2 |

Conclusion

We hope that our material will help the reader to begin his acquaintance with modern heating equipment. As usual, in the attached video you can find additional thematic information. Successes!