Brick heating stoves: the main types and features of choice

In this article we will talk about what kind of heating brick ovens with their own hands are built in accordance with traditional methods. Again, we will consider the fact according to which criteria the design of the furnaces can be chosen.

In spite of the fact that the traditional brick heating furnace with its own hands, built everywhere, has been in operation for many hundreds of years, its relevance does not become less. Moreover, such facilities are widely used along with other more traditional heating systems.

The advantages of self-erection

Brick heating furnaces with their own hands are built by chance, because there are a number of good reasons for this, including:

- relatively low price of the finished structure;

- universality in terms of fuel used (almost everything that burns, including firewood, coal, pellets, pressed heating briquettes, waste of economic activities, etc.) can be used;

- aesthetically appealing look that will fit into most interiors;

- high efficiency (depending on the type of fuel used);

- ease of operation and maintenance of their own hands;

- versatility, since the device for heating can be supplemented by a stove bench, oven, and other equally useful devices.

Main criteria for furnace classification

Before the heating brick oven will be built with your own hands, it is necessary to choose the best option in accordance with the following criteria:

- functional purpose;

- temperature with which walls heat up;

- the time needed to burn fuel;

- intensity of heating and heat transfer.

- exhaust gas circuit;

- chimney construction;

- structure configuration;

- materials used in the finishing of the outer walls.

In accordance with the listed features, the following list of modifications can be distinguished.

Heating stoves

The heating furnace from a brick is built by hands for a long time. But, despite its traditional character, these structures have one major drawback - they are not sufficiently functional. In other words, these furnaces are designed for heating of closed rooms with long-term accumulation of heat in their walls.

Such structures are usually classified according to the parameters of heat transfer, with the time of the firebox and with the degree of heating of the walls.

For example, furnaces, which are characterized by moderate heating, are placed with the thickness of the outer wall of at least half of the brick or in one brick. As a result, the structure slowly heats up, but also slowly cools, gradually releasing heat to the external environment.

On average, the temperature of the outer wall reaches + 60 ° С. Therefore, brick heating furnaces for the house are considered the most heat-intensive, but also the most massive. Such heating equipment has the most comfortable heat, which has no smell of burning dust.

In spite of the fact that traditional heating installations do not differ either in beauty or functionality, a large amount of brick is required for their construction. Again, the construction process is labor-intensive.

Typical examples of furnaces intended only for heating are: “Dutch”, OPT-3 (plastered), OTP-11 (heat capacity 4.9 kW), thick-walled rectangular and triangular furnace, “Groom-Gryrizheylo”, etc.

Heating and cooking modifications

Of course, the design of brick heating furnaces are not limited to low-functional buildings designed only for heating indoor spaces. For example, about 90% of furnaces in the territory of the Russian Federation combine the function of heating and cooking.

A structural feature of such structures is the presence of a cast-iron stove and oven. In addition, for greater functionality, the oven can be equipped with a camera designed for baking bread, a niche for drying firewood, etc. The efficiency of such facilities on average is about 60% with a heat capacity of up to 4 kW.

Important: As well as only heating facilities, stoves with a hob are able to maintain stable traction and retain heat for a long time.

A typical example of current heating and cooking facilities are such furnaces as the Swede, “Baby”, “Teplushka”, “Housekeeper”, the high-performance Volkov oven, etc.

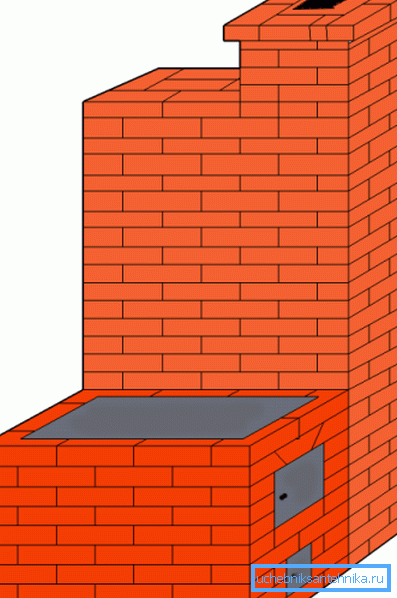

Kitchen brick plates with heating shields

These heating brick ovens on the side can have a hob suitable for daily cooking. But, in contrast to the previous version, such furnaces are not only functional, but also the most affordable solution, both in terms of material consumption and in terms of labor costs.

For example, an average of 175 bricks is enough for laying such a structure. And, despite the small expenditure of building materials, the presence of a thermal shield allows you to heat a small room with a limited amount of fuel used.

Important: Due to the low cost, this option has increased demand among summer residents retired.

Today there are a lot of kitchen brick slabs, which, in addition to cooking, can be used as the main heating of an enclosed space. The most common options are: kitchen stove with oven, stove with hot water boiler and oven, three-channel heating shield for cookers, kitchen stove on trenches, etc.

Brick Kamenka for a bath

Classic brick stoves with a heating boiler can be used not only for heating an enclosed space, but also as equipment for equipping baths and saunas.

At the moment, well-built heaters are in no way inferior to modern metal structures made of metal. On the other hand, only a brick heater is capable of providing real dry steam, which makes the bath a bath.

Among the advantages of the heater, we especially note the heat capacity, due to which the air in a closed room does not cool down within two days. Again, due to the fact that the heater is assembled from bricks, there is no smell of heated metal in the steam room and in the washing room.

Furnace classification according to other parameters

In addition to the above parameters, the classification of furnaces is carried out in accordance with the following parameters:

- External wall temperature:

- moderate heating - no more than + 90 ° С;

- increased heating - no more than + 120 ° С;

- high heat - more than + 120 ° С.

- In accordance with the scheme of movement of heated air through the channels:

- with parallel single or double turn channels;

- with multiturn serially connected channels;

- bell-free modifications;

- with the system of combined turns.

- In accordance with the form:

- rectangular;

- polygonal;

- angular triangular;

- round;

- with a complex configuration.

- In accordance with the exterior:

- tiled and tile;

- laying under laying;

- masonry with surface grouting;

- plastered, whitewashed and painted.

Conclusion

At present, it is not difficult to find projects of heating furnaces made of bricks that are professionally developed and tested in real conditions. But, in order to provide the necessary functionality of the furnaces, it is necessary, in accordance with the above criteria, to choose the best option that will correspond to the characteristics of the construction project and your budget (see also Heating and Cooking Brick Ovens - universal devices for a country house).

In addition, the correct choice of heating stoves will significantly reduce fuel costs. You can find more useful information by watching the video in this article.