Calculation of heat load on the heating and related

How is the calculated thermal load on heating calculated? What factors affect the home's need for heat? How to choose the optimal heating devices? In the article we will try to answer these and some other questions.

Easier, even easier

Immediately make a reservation: this article is aimed at owners of private houses and apartments with independent heating. Methods of calculating the heating systems of multi-apartment buildings are quite complex and must take into account a lot of factors: the work of ventilation, the wind rose, the degree of insolation of the building, and much more.

In the case when it comes to heating a small house, it is easier to pick up the heat output with a certain margin. The price of several additional sections of the battery hardly seems ruinous against the background of the total cost of construction.

Operating costs, however, with proper organization, will not increase at all: thermostats and chokes will limit the thermal capacity on warm days when it will not be in demand.

So: our goal is to learn how to calculate the load on heating in the most simple and understandable ways for a non-specialist.

What we think

We have to learn how to count:

- Total heat output (total power of heating devices, and in the case of an autonomous system, also the power of the boiler).

- Separate heater power in a single room.

In addition, we will touch on several related values:

- Calculation of the amount of coolant and the volume of the expansion tank of the heating system.

- Selection of the performance of the circulation pump.

- Selection of the optimal filling diameter.

Total heat output

By area

Half a century ago, SNiPs offer the simplest calculation scheme that many use to this day: 100 watts of heat are taken per square meter of heated space. On a house of 100 squares need 10 kW. Point.

Simple, understandable and too inaccurate.

The reasons?

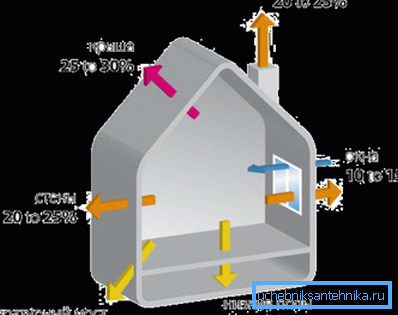

- SNiPs were developed for apartment buildings. Heat leaks in an apartment surrounded by heated premises and in a private house with ice air beyond the walls are incomparable.

- The calculation is correct for apartments with a ceiling height of 2.5 meters. A higher ceiling will increase the volume of the room, and, consequently, the cost of heat.

- Through windows and doors, much more thermal energy is lost than through walls.

- Finally, it will be logical to assume that the heat losses in Sochi and Yakutsk will vary greatly. Increasing the temperature delta between the room and the street will double the heat consumption for heating exactly twice. Physics, however.

By volume

For premises with standardized thermal resistance of enclosing structures (for Moscow - 3.19 m2 * C / W), you can use the calculation of thermal power by volume of the room.

- 40 watts of heat is taken per cubic meter of heated apartment volume. For a cubic meter of volume of a private house without common walls with neighboring heated buildings - 60.

- 100 watts of thermal energy is added to the base value for each window. For each door leading to the street - 200.

- The power received is multiplied by the regional coefficient:

| Region | Coefficient |

| Krasnodar, Crimea | 0.7-0.9 |

| Leningrad and Moscow regions | 1.2-1.3 |

| Siberia, the Far East | 1.5-1.6 |

| Chukotka, Yakutia | 2.0 |

Let's once again calculate the need for heating thermal power for a house with an area of 100 squares, but now we specify the task:

| Parameter | Value |

| Ceiling height | 3.2 m |

| Number of windows | eight |

| Number of doors leading to the street | 2 |

| Location | G. Tynda (average January temperature is -28 ° C) |

- The height of the ceilings of 3.2 meters will give us an internal volume of the house of 3.2 * 100 = 320 m3.

- The basic thermal power will be 320 * 60 = 19200 watts.

- Windows and doors will do their bit: 19200+ (100 * 8) + (200 * 2) = 20,400 watts.

- The invigorating cold of January will force us to use a climate coefficient of 1.7. 20400 * 1.7 = 34640 watts.

As it is easy to see, the difference with the calculation according to the first scheme is not only great - it is striking.

What to do if the quality of the house's insulation is significantly better or worse than the building regulations require? Thermal protection of buildings?

By volume and coefficient of warming

The instruction for this situation comes down to using a formula of the form Q = V * Dt * K / 860, in which:

- Q - the cherished indicator of thermal power in kilowatts.

- V - Volume of heated space.

- Dt is the delta of temperatures between the room and the street at the peak of the cold.

- K - coefficient depending on the degree of insulation of the building.

Two variables require separate comments.

Delta temperatures are taken between the prescribed SNiP dwelling temperature (+18 for regions with lower winter temperatures down to -31 ° C and +20 for areas with stronger frosts) and an average minimum of the coldest month. Focusing on the absolute minimum is not worth it: record cold is rare and, sorry for the involuntary pun, the weather does not.

The coefficient of heat insulation can be derived by approximating the data from the following table:

| Insulation coefficient | Walling |

| 0.6 - 0.9 | Foam or mineral wool coat, insulated roof, energy-saving triple glazing |

| 1, -1.9 | Brick laying in one and a half brick, single-chamber double-glazed windows |

| 2 - 2.9 | Brickwork, windows in wooden frames without insulation |

| 3-4 | Laying in half-brick, glazing in one thread |

Let us once again carry out the calculation of the heat loads on the heating for our house in Tynda, specifying that it is insulated with a foam plastic coat 150 mm thick and protected from the weather by triple-glazed windows.

Actually, otherwise modern houses in the conditions of the Far North are not built.

- The temperature inside the house is assumed to be +20 C.

- The average minimum of January will be helpfully prompted by the well-known Internet encyclopedia. It is -33C.

- Thus, Dt = 53 degrees.

- We take the coefficient of heat insulation equal to 0.7: the heat insulation described by us is close to the upper limit of efficiency.

Q = 320 * 53 * 0.7 / 860 = 13.8 kW. It is this value that is worth being guided by when choosing a boiler.

Selection of power of the heating device

How to calculate the thermal load on the contour section corresponding to a single room?

Simply simple: perform the calculation on one of the above schemes, but for the volume of the room. For example, a room of 10 m2 will have exactly 1/10 of the total heat output; according to the calculation according to the last scheme, it is equal to 1380 watts.

How to choose a heater with the desired characteristics?

In the general case, simply by examining the documentation for the radiator or convector you have observed. Manufacturers usually indicate the heat flux value for a single section or the entire instrument.

Nuance: the heat flow is usually indicated for the 70-degree temperature delta between the coolant and the air in the room. Reducing this delta by half will cause a two-fold drop in power.

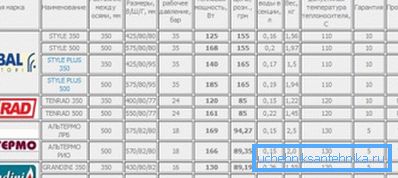

If for some reason the documentation and the manufacturer’s website are not available, you can use the following average values:

| Type of sectional radiator | Heat flow to one section, watts |

| Cast iron | 140-160 |

| Bimetallic (steel and aluminum) | 180 |

| Aluminum | 200 |

We should also specify the calculation of the heat transfer register.

For a horizontal pipe of circular section, it is calculated by the formula Q = Pi * Dn * L * k * Dt, in which:

- Q - thermal power in watts;

- Pi is the number pi taken to be 3.1415;

- Dн is the outer diameter of the register section in meters.

- L - pipe length in meters.

- k is the coefficient of thermal conductivity, which for steel pipe is taken to be 11.63 W / m2 * C;

- Dt is the temperature delta between the coolant and the air in the room.

A typical register consists of several sections. At the same time, all of them, except the first, are in the upward flow of warm air, which reduces the Dt parameter and directly affects the heat transfer. That is why an additional factor of 0.9 is used for the second and other sections.

Let's follow the example of this calculation.

Let's calculate the heat capacity of a four-section register with a length of three meters, made of a pipe with an outer diameter of 208 mm, at a coolant temperature of 70 degrees and an air temperature in the room of 20 degrees.

- The power of the first section will be 3.1415 * 0.208 * 3 * 11.63 * 50 = 1140 watts (rounded to the whole number).

- The power of the second and other sections is equal to 1140 * 0.9 = 1026 watts.

- The total thermal power of the register is 1140+ (1026 * 3) = 4218 watts.

Expansion tank capacity

This is one of the parameters that need to be calculated in an autonomous heating system. The expansion tank must contain the excess coolant during its thermal expansion. The price of its insufficient volume - constant operation of the safety valve.

However: the overestimated volume of the tank does not have any negative consequences.

In the simplest version of the calculation, the tank is taken equal to 10% of the total amount of coolant in the circuit. How to find out the amount of coolant?

Here are a couple of simple solutions:

- The system is filled with water, after which it merges into any dimensional dishes.

- In addition, in a balanced system, the volume of coolant in liters is approximately equal to 13 times the power of the boiler in kilowatts.

A more complex (but also giving a more accurate result) tank calculation formula looks like this:

V = (Vt x E) / D.

In it:

- V is the required volume of the tank in liters.

- Vt is the volume of coolant in liters.

- E is the expansion coefficient of the coolant at the maximum operating temperature of the circuit.

- D - tank efficiency ratio.

And in this case, a couple of parameters need comments.

The coefficient of expansion of water, which often acts as a coolant, when heated from the initial temperature of + 10C can be taken from the following table:

| Heating, C | Expansion,% |

| thirty | 0.75 |

| 40 | 1.18 |

| 50 | 1.68 |

| 60 | 2.25 |

| 70 | 2.89 |

| 80 | 3.58 |

| 90 | 4.34 |

| 100 | 5.16 |

Useful: water-glycol mixtures used as antifreeze for heating circuits, expand when heated slightly stronger. The difference reaches 0.45% when heated to 100 degrees of a 30 percent glycol solution.

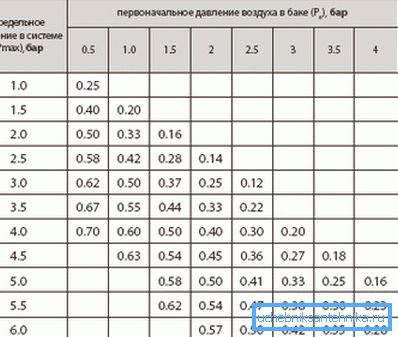

The expansion tank efficiency coefficient is calculated using the following formula: D = (Pv - Ps) / (Pv + 1).

In it:

- Pv is the maximum allowable working pressure in the circuit. It is set to trigger the safety valve. As a rule, it is chosen equal to 2.5 atmospheres.

- Ps - tank charging pressure. It usually corresponds to the height of the water column in the circuit above the tank. For example, in the heating system, where the top of radiators on the second floor rises above a tank mounted in the basement, 5 meters, the tank is charged with a pressure of 0.5 atmosphere (which corresponds to a five-meter head).

As an example, let's do a do-it-yourself tank calculation for the following conditions:

- The volume of coolant in the circuit is 400 liters.

- Heat carrier - water heated by the boiler from 10 to 70 degrees.

- The safety valve is set at 2.5 kgf / cm2.

- The expansion tank is inflated with air to a pressure of 0.5 kgf / cm2.

So:

- The tank's efficiency ratio is (2.5-0.5) / (2.5 + 1) = 0.57.

- The coefficient of expansion of water when heated at 60 degrees is 2.25%, or 0.0225.

- The tank should have a minimum volume of 400 * 0.0225 / 0.57 = 16 (rounded to the nearest value from the tank size range) liters.

Pump

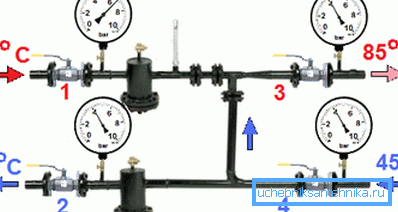

How to choose the optimal pressure and pump performance?

With all the pressure is simple. Its minimum value of 2 meters (0.2 kgf / cm2) is sufficient for the contour of any reasonable length.

Reference: the heating system of an apartment building functions when the difference between the mixture and return flow is exactly two meters.

Performance can be calculated according to the simplest scheme: the entire volume of the contour should turn around three times per hour. So, for the above-mentioned amount of coolant in 400 liters, the reasonable minimum performance of the circulating pump of the heating system with an operating head should be equal to 0.4 * 3 = 1.2 m3 / hour.

For individual sections of the circuit, equipped with its own pump, its performance can be calculated by the formula G = Q / (1.163 * Dt).

In it:

- G - cherished performance value in cubic meters per hour.

- Q is the heat output of the heating system section in kilowatts.

- 1.163 - constant, average heat capacity of water.

- Dt is the temperature difference between the supply and return lines in degrees Celsius.

Hint: in autonomous systems, it is usually taken equal to 20 degrees.

So, for a circuit with a thermal power of 5 kilowatts at a 20-degree delta between the flow and return flow, a pump with a capacity of at least 5 / (1.163 * 20) = 0.214 m3 / h is needed.

Pipe diameter

How to choose the optimal filling diameter in the circuit with a known heat output?

The formula D = 354 * (0.86 * Q / Dt) / v will help here.

In it:

- D is the internal diameter of the pipe in centimeters.

- Q is the thermal power of the circuit in kilowatts.

- Dt is the delta temperature between the flow and the return pipe. Recall that the typical value of Dt for an autonomous heating system is 20 C.

- v is the flow rate. The range of its values is from 0.6 to 1.5 m / s. At lower speeds, the temperature difference between the first and last radiators in the circuit increases; at higher levels, hydraulic noise becomes noticeable.

Let's calculate the minimum diameter for the notorious contour with a capacity of 5 kW at a water velocity in the pipes of 1 m / s.

D = 354 * (0.86 * 5/20) / 1 = 4.04 mm. On the practical side, this means that you can take pipes of the minimum available size and not be afraid of slow circulation in them.

Conclusion

We hope that the abundance of formulas and dry numbers is not tired of a respected reader. As usual, the attached video will offer its attention to additional thematic information. Successes!