Cast iron heating radiators - past and future

Before the appearance of aluminum and bimetallic radiators in our apartments, the main devices of the central heating system were cast iron. Despite the venerable age, and the products are used for heating for more than 100 years, they are still in demand among consumers. They acquire them, despite the shortcomings of the equipment. Our task today is to find out why it is so popular and what modern cast-iron radiators are waiting for in the future.

Distinctive feature

Even after the appearance of alternatives in the form of bimetallic or aluminum sections, cast iron radiators have not lost their fans. Most likely, this lies in their technical characteristics, which could prove to everyone that heating devices made of cast iron meet all requirements.

We believe that they should be described in more detail:

| Rust resistance | Cast iron is not susceptible to corrosion, which is an important property, especially when water is drained from the system in summer. |

| Durability | Very important product advantage. If you follow all the rules of operation, including regular maintenance, cast iron batteries for home heating will be able to stand without repair for almost half a century. |

| Quality of the heat carrier | Alas, in centralized heating systems the quality of water leaves much to be desired. It contains various chemical compounds, particles of rust, alkali and others, to which the internal surfaces of the radiator do not react. In addition, scratching and dissolving the cast iron is not so easy. |

| Clogging | Wide channels provide normal circulation of the coolant. Therefore, even if there are foreign objects or deposits in the system, this will not be a problem. |

| Storage capacity | Products made of cast iron are very thermally inert. They gain it for a long time, but then give it back for a long time if there is a system shutdown. For example, in an hour the heat transfer will be 30%. If the heat supply periodically turns off, the batteries will be able to smooth out its short-term absence. |

Tip: cast iron radiators can withstand temperatures up to 150 ° C, and therefore they can be used in a steam heating system.

Additional benefits:

- The walls of the radiator are thicker, which also contributes to the durability of the device operation.. This is especially ideal for open-type heating systems where there is always a high level of oxygen.

- Low price gives access to products to people with low material wealth. It should be recognized that the cast iron radiator is much cheaper than other metal alloys. When equipping a house, such savings can be decisive.

Among the shortcomings, the following should be noted:

- A large mass of the product, so one can not cope with it alone, you will need help.

- Impressive dimensions, when compared with modern bimetallic or aluminum counterparts.

- An average of 45 kilograms of battery weight is output per 1 kW of thermal energy. The indicator is much inferior to the same bimetallic or aluminum registers.

- The maximum pressure for which they are designed is up to 15 bar, although for bimetallic ones this parameter is up to 40 bar.

- Low heat emission, due to which the heating of the room is slow.

- Intersectional space of complex shape, so the radiator is difficult to clean from dust.

How to choose

Before sending to the store for a cast iron radiator, you should consider some technical criteria:

- section heat transfer parameter, which will help to choose the product in accordance with the dimensions of the heated room;

- the total mass of the radiator, it is necessary to select the place of attachment;

- height, width and depth of the device;

- total register power.

To calculate the heat capacity of a cast iron battery for each individual room, use the following rule:

- for a room with a 1st window and a 1st outer wall, 1 kW of heat transfer per 10 m2 is enough;

- 1.2 kW / 10 m2 will be required for placement with two external walls and one window;

- 1.3 kW / 10 m2 is necessary for heating a room with 2 windows and 2 exterior walls.

We recommend also to pay attention to such factors:

- power counts with a standard ceiling height of 2.5 m, in case of an increase in the parameter, it must be increased proportionally;

- If the room is equipped with double glazed windows, the estimated capacity can be reduced by 15%.

Tip: calculate the number of sections needed by dividing the total power required for heating a room by the capacity of one section.

The instruction recommends installing radiators under each window in the room. So you will be able to significantly reduce heat loss.

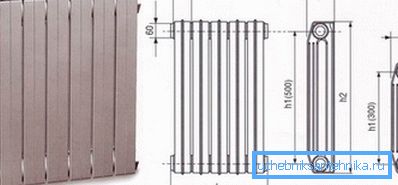

Standard dimensions of cast iron radiators:

- section width - 40-60 mm;

- depth - 110 mm;

- center distance - 500 mm.

Modern tendencies

Implementing old models to manufacturers is becoming more and more difficult, so today the market is trying to capture the buyer with original design. Most of us at the mention of cast iron radiators immediately associate with something rough and unaesthetic.

Therefore, designers and designers decided to breathe new, fresh solutions into the product:

- On the surface of the device can now be depicted a beautiful ornament, which coincides with the style of the room.

- Managed to reduce the size, while increasing heat transfer.

- The ribs began to be arranged vertically, which also increased the heat transfer, and cleaning now passes without problems.

- New dimensions were added, which made it possible to place heaters of a new generation in a small window-shed niche.

- Appeared on some models of the legs, which saved the homeowners from drilling the walls. Now the radiator can be installed on the floor and connected to the heating network with your own hands.

- The color palette was also varied, in which green and violet tones, copper and bronze, silver and gold are found.

- Recently, reproductions of old models of radiators, which resemble samples of distant ages, have gained popularity. They are decorated with art casting and staffed with appropriate fittings. These exquisite models of products help to elevate the interior, becoming part of it. The cost of such products, of course, is higher than standard ones, but you can choose or order an individual model that will suit your taste and preferences.

What to choose - domestic model or foreign

Our market includes companies from many countries, including Germany, Great Britain, China, the Czech Republic, Turkey, Italy and Spain. Their difference from domestic products is better and aesthetic surfaces. In addition, the thermal capacity of the device remains the same, but its dimensions are significantly reduced.

For example, in the Czech radiator, 800 ml of heat carrier is placed in the section, whereas in the Russian classical MS-140 it is 1.3 liters. So with the same heat transfer, the foreign version will be smaller and lighter.

The internal surface of foreign radiators is almost perfectly smooth, and this helps to reduce the resistance to movement of the coolant and does not allow the formation of scale on the walls of the battery.

Also, imported versions are already offered in a painted form, while domestic ones need painting after installation. One of the disadvantages of imported products is the high cost of models, which significantly exceeds the cost of domestic samples.

Conclusion

Cast iron radiators are an acceptable option for the heating system in apartments and in private houses. They are still in demand among the population. If you want them to serve for a long time, you need to properly install and connect them. The video in the article will help you find additional information on this topic.