Cast iron solid fuel boilers - classics of the genre

If the design of the heating system focuses on maximum autonomy, then the boiler can not do. Cast iron solid fuel boilers can be considered as the basis of a reliable and durable heating system. Due to the fact that for the production of the boiler is used no more than the usual steel, and cast iron, it acquires a number of useful properties, they will be discussed below.

Types of solid fuel boilers

At first glance, the principle of operation of any boiler is the same - the fuel is burned (solid, liquid or gaseous), and the resulting heat is sent to the heated coolant. In fact, there may be several combustion modes, and the design of the boilers differs significantly from each other.

As for solid fuel devices, it is possible to distinguish such types of boilers as:

- simple cast iron solid fuel boiler - the word simple means that the fuel simply burns in the firebox. Can work on wood, coal, pellets, waste wood processing industry, etc.

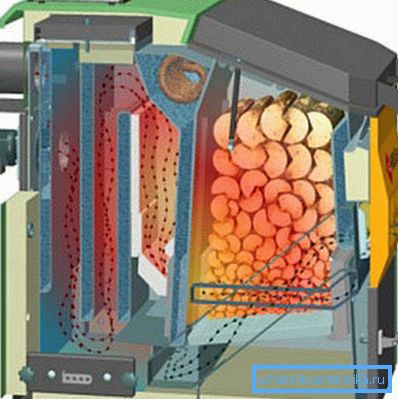

- gas generator type (it is a long-burning boiler or pyrolysis) - in this case, the emphasis is placed on the most complete combustion of fuel. For this, the firebox consists of 2 zones, the fuel is in one, and the pyrolysis gas is burned in the other. More on the principle of operation of such devices - later in the article;

- boiler Stropuva - it is interesting first of all by its design. The furnace in the form of a cylinder is placed in another cylinder, and the space between the walls is filled with coolant. Due to the large volume of the furnace such a boiler can work up to several days.

Note! The work of such a boiler is quite easy to regulate, and its popularity is facilitated by the simplicity of the design. In comparison, for example, with a pellet boiler the price of such a “matryoshka” will be much lower.

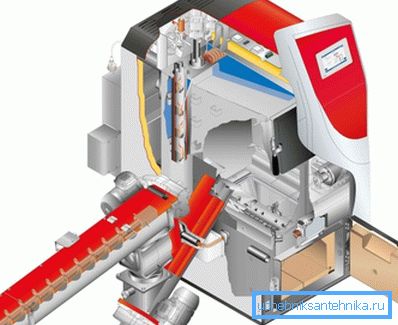

- fully automatic devices - All listed boilers should be cleaned regularly, because the fuel does not burn at 100%. Therefore, even in the most modern boilers, manufacturers arrange ash pits - for cleaning. In automatic boilers, not only the cleaning process is automated, but also the process of supplying fuel to the furnace.

Note! The fuel supply is usually organized by a conveyor belt, so that such a heating system will depend on electricity. This should be taken into account when designing heating outside the city, where interruptions in electricity are not such a rarity.

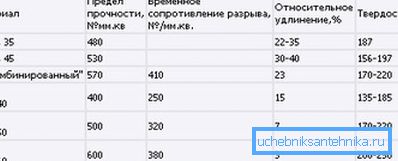

Comparison of steel and cast iron boilers

When choosing a boiler, it is necessary to understand that cast-iron devices differ in a number of parameters from steel ones.

Comparing iron and steel boilers, it can be noted that:

- cast iron in comparison with steel is much more fragile material, respectively, shocks during transportation are contraindicated;

- if the steel heats up rather quickly, the cast iron structure is much slower. But to cool such a boiler will not be as fast as steel;

- Cast iron is practically not subject to corrosion. Rather, to say that this process proceeds with the metal several times slower than with steel. The maximum that will happen is that rust will manifest itself on the outside of the metal, but it will practically not go deep into it;

- A steel boiler is a monolithic device, that is, during its installation and transportation, certain difficulties may arise. Solid cast iron boilers - block construction, that is, it can simply be disassembled into separate blocks and moved to another location;

- Cast iron does not tolerate sudden changes in temperature. If cold water gets on the hot metal, for example, it will most likely just crack.

Note! In order not to risk, it is not recommended to load even too cold fuel into the furnace.

How does a cast iron pot

In the production of steel boilers, welding is used, due to which a monolithic structure is obtained at the outlet. In the case of cast iron, welding is not used, and the necessary elements are made by casting. Then the individual sections are connected into one, by changing the number of sections, you can adjust the power of the boiler.

In the general case, cast iron can be welded; it suffices to arm yourself with iron-nickel electrodes (UTP 86FN) and deeply cut the seam. But this process is rather troublesome, so it is not suitable for mass production.

Note! Even when welding is performed according to all the rules, the seam can be fragile, therefore, if a section has a crack, then only its complete replacement will help, it’s better not to think about repair.

Device and principle of operation

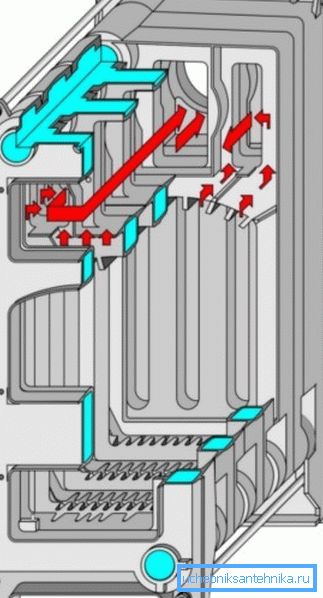

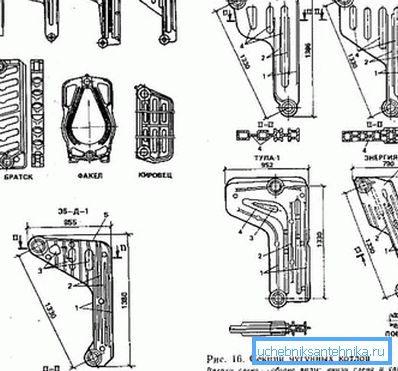

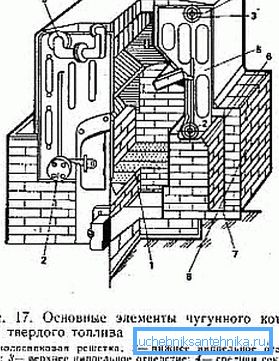

Heating cast iron boilers for solid fuels may differ not only in power and size, but also in shape. There can be devices consisting of L-shaped sections, such structures are placed in finished form above the brickwork of refractory bricks, the furnace and ducts are made of it, and the heat carrier circulates through the channels inside the sections themselves.

Sections made in the shape of the letter “O” are located around the furnace, such design is typical for gas boilers.

As for the assembly of sections, then for each boiler it is different, it is possible to note only general points:

- for assembly at the stage of production of sections, the manufacturer provides holes;

- Conical nipples and coupling bolts (they will pass through the nipples when assembling) must be supplied with the boiler.

- when installing, special attention should be paid to the tightness of the joint, to achieve this, asbestos cord and graphite paste are used. Installation instructions allow for docking individual sections to coat the joint with special mastic. The distance between individual sections of more than 2 mm is not allowed.

As for the principle of operation, the inlet of the cooled coolant is usually organized from the rear bottom of the structure. Water consistently passes through the corresponding channels in the connected sections and comes to the front of the boiler already hot, ibid (in the upper part) and the flow of coolant into the heating circuit is organized. From the outside, the structure is covered with a decorative metal casing.

It is undesirable to use cast iron boilers, if the temperature of the coolant will exceed 105? C, and the pressure in the system - 0.7 kgf / cm2. As already mentioned, cast iron material is fragile, and the replacement of sections is not a cheap pleasure.

Simple Home Boilers

Cast iron heating boilers for solid fuels can simply be purchased in the store and get ready for installation design. In this case, the installation process of the boiler is reduced to the fact that it is simply installed on a flat surface, and the pipes of the heating system are connected to the outlets.

The simplest devices are a conventional firebox in which fuel and a heat exchanger are burned, in which water is heated to a temperature of about 90-95? C. Much more interesting is the pyrolysis device (gas generator boiler).

The main disadvantage of simple combustion of solid fuels is that the pyrolysis gas is simply drawn into the chimney, and in fact, when it is burned, a lot of energy is released. Pyrolysis boilers of this lack are deprived of firewood rather than intensive burning, and the gas released is burned before entering the chimney.

Such a solid cast iron boiler has a fire chamber divided into 2 chambers - the first one is loaded with fuel, and the second is supplied with pyrolysis gas and is burned in it. Particular attention in such devices is paid to adjusting the flow of air; it must be metered in order for the entire volume of fuel to be exposed to high temperatures but not to burn.

What to look for when choosing

When choosing a specific boiler model, cost is often the main criterion, but this is not quite the right approach, because you also need to consider reliability, serviceability and a number of other parameters.

From a technical point of view, you need to pay attention to such features:

- if there is a lining in the combustion chamber - the lining protects the walls from the effects of high temperature. If not, then fuel consumption increases;

- layer of insulation - it is desirable that the boiler was with factory insulation, it will help to minimize heat loss;

- Next you need to decide what should be the heating system. If it is necessary to achieve maximum autonomy, then it is not recommended to use a smoke exhauster, supercharging, but if there are no problems with electricity supply, then supercharged boilers are a good choice. Due to this, even in bad weather it will be good.

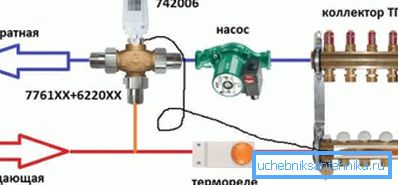

There are some subtleties when tying the boiler, especially if the installation is done by hand. It is necessary to ensure that the cooled coolant entering the boiler is not too cold - otherwise the heat exchanger may crack at the most inappropriate moment.

In order to avoid this, a simple 3-way valve (with a thermoelement) is added to the heating circuit. Thanks to him, before the cold coolant enters the boiler, there will be a dome of hot water from the supply pipe.

When choosing, you need to take into account one more thing - compared with domestic manufacturers, imported counterparts sometimes have a heat exchanger wall that is much thinner. This is due to the more advanced casting technology, so that for each boiler an acceptable temperature difference will be different.

Summarizing

Despite a number of drawbacks, such as high inertia, somewhat higher cost and weight, cast iron boilers remain popular. Not least this is due to high durability and corrosion resistance of the metal.

The proposed material will allow you to familiarize yourself with the main features of heating solid fuel boilers made of cast iron and decide whether such a device is suitable for your heating system.

The video shows the strengths and weaknesses of cast iron and steel solid fuel boilers.