Ceiling infrared heating: how to heat large rooms with high

Practically every master who is used to doing housework with his own hands is familiar with traditional climate control systems, in which the main heating elements are radiators. But there are other ways to heat the room. In particular, ceiling infrared panels for heating.

They are simply indispensable for arranging zone heating and are often installed in spacious rooms with high ceilings. On their types and installation procedure, read on.

Basic concepts

The principle of operation of infrared emitters

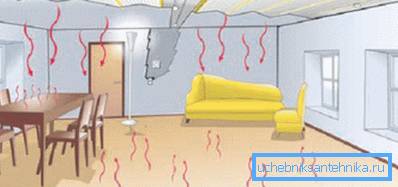

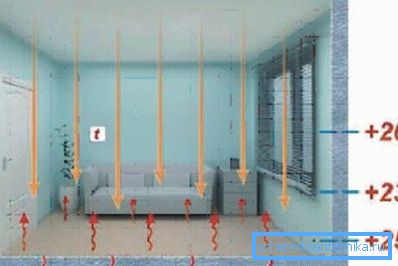

If heating radiators and convection heaters raise the temperature of the air masses, the infrared rays heat the objects themselves, which are in the room and fall into the radiation zone of the device. Thanks to this, after 1-2 minutes after switching on, comfortable conditions are established in the room for people to be there.

The advantages of using infrared radiation are as follows:

- equipment has a very high efficiency (for ceiling electric film panels, this figure is 98%);

- small size - after installation and completion of construction works, infrared panels will not be visible at all.

Varieties of infrared heaters

Modern industry produces many climatic devices using infrared radiation. They differ in the type of energy used and the main application.

The following types of devices can be found in hardware stores:

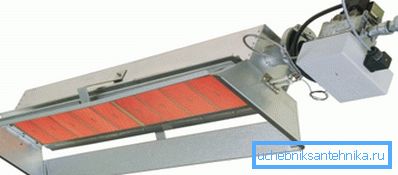

- Gas heaters. In this case, heat waves emit plates of a special material, which, in turn, are heated by the burned gas mixture.

Note! Gas infrared emitters have a very large power, because it can hardly be used indoors. More often such constructions are used for heating of industrial and commercial buildings with a large area.

- Electric emitters. The most common kind of devices. In this case, infrared waves emit special spirals or heat-electric heaters. To improve the efficiency of operation, the heaters can be additionally equipped with reflectors and heat diffusers.

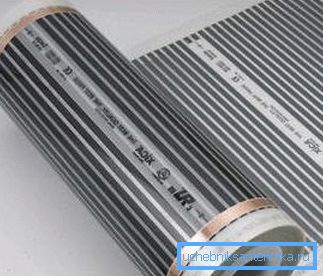

- Film IR Panels. On a special substrate carbon fiber threads are glued, which are sources of thermal energy. Most often, these types of heating elements are fixed on the ceiling and masked with a decorative coating. Great for heating rooms with high ceilings (more than 2.5 meters).

As for the scope of application, there are:

- Infrared Emitters for Industrial Use. They consume a large amount of electricity or gas, but have high power. They are rather large in size and not very sophisticated design, therefore they are very rarely installed in dwellings.

Commercial-use infrared heaters can be used to heat open terraces, parks, playgrounds, and so on.

- Household Heaters. This category includes infrared films and special emitters that are powered by electricity. They have an attractive appearance and fit perfectly into the interior of the room.

Choosing the right model

Radiators that heat a room using infrared rays can be used as the main source of heat or as a backup system, which can be turned on in the event of a breakdown or insufficient efficiency of the main network.

With the continuous use of the described devices, it is necessary to correctly calculate their power:

- for rooms with ceiling heights up to 3.5 meters - 1 kW per 1 m3 squares;

- with a greater distance between the floor and the ceiling - 1.3 kW per 1m3 square

In addition, the following factors should be taken into account:

- thickness and material of the exterior walls of the building;

- the presence or absence of a warming layer and the material used for it;

- the type of installed window units, the number of window openings, double-glazed windows, and so on;

- thermal insulation characteristics of ceiling and interfloor overlappings.

Fixing electric infrared heaters

The easiest way to arrange heating with infrared radiation is to install special heaters manufactured by domestic and foreign manufacturers.

This process does not require a detailed description, but in order for the result not to disappoint you, you must follow these requirements:

- buy reliable fixing accessories that will firmly hold the device (it is advisable to use the brackets that come with the device);

- make sure that the edges of the device do not come into contact with combustible materials;

- It is necessary to carefully isolate the junction of electrical wires with polymer tape or special caps.

The procedure for mounting film infrared emitters

The installation of infrared emitters should be subject to certain rules, failure to comply with which can lead to equipment breakage and harm to human health.

In particular, the installation instructions provide for compliance with the following rules:

- the ceiling on which heaters are mounted must have a certain height (at least 2500 cm);

- it is forbidden to position the radiators so that the flow of infrared rays is directly directed at the person (for example, above the bed in the bedroom);

- heaters should not be installed near window openings;

- If the room is supposed to install IR panels, the ceiling should not be covered with decorative materials from polymers.

Tip! When infrared ceiling heating is installed in a small room, you can do the work yourself, otherwise you will need to carry out complex construction work, which must be preceded by engineering calculations. It is better to entrust the work of specialists.

The process itself consists of several stages, each of which is described in detail below.

Installation of insulation

Thermal insulation material used in the installation of infrared heaters must, in addition to the low thermal conductivity coefficient, have a reflective screen of metal foil.

The optimal layer thickness is 5 mm, if the ceiling is made of heat-conducting materials, you can take a 10-mm insulator. In addition, you will need a construction stapler (if the ceiling is wooden or support beams are installed on it) or special fixing hardware with dowels and wide caps (in the case when the ceiling is made of concrete).

The scheme of work is as follows:

- heat insulator sheets are laid on the surface and fixed in increments of no more than 50 cm;

- between adjacent sheets you need to do overlap width from 2 to 3 cm;

- to improve the reflective properties of the seams are glued with a special adhesive foil tape.

Fixing IR panels

Structurally, the infrared film heater is a plate of carbon, on which conductive carbon fibers are glued. In addition, each element has special places for fixing them on a vertical or horizontal surface.

The order of installation of heating elements is the same as when installing a heat-reflecting material. The same tools and materials are used.

Note! Film infrared heaters can only be fixed in transparent fields located on their edges (they are specially designed for this). Otherwise, you can spoil the device, the price of which is not so small.

If you doubt your abilities or have insufficient experience in carrying out plumbing work, it is recommended to contact specialists who not only perform the task qualitatively, but also guarantee quality.

Electrical connection

In order for infrared emitters to perform their functions, they must be connected to electricity.

This is done as follows:

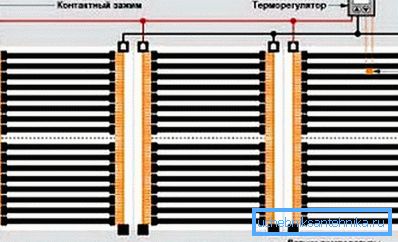

- A little away from the heating films in the surface of the ceiling, a strobe is made for laying electrical cables feeding the heaters into it. The trunk line is made of a single-conductor cable of a suitable cross section (depending on the number of emitters). The devices themselves are connected in parallel.

- At the end of the installation, all joints are carefully insulated, and the cable channel is closed so as not to spoil the appearance of the room.

- After that, an automatic thermostat for heating is installed. Its temperature sensor should be at a height of about one and a half meters from the floor. If the room is small, the control device is simply inserted into the break of the supply cable.

- In larger premises, the wiring diagram is different. Wires from all panels are collected in a special control panel, where magnetic contactors are installed, controlled by a thermostat.

At the end of the work, the system is tested in all existing modes. If it is successful, you can mount decorative materials on the ceiling.

Conclusion

Infrared heating is a very efficient and easy to install climate system. However, its use as the main one may entail increased power consumption, which is more expensive than the gas consumed by an autonomous boiler (see also the article Infrared film for heating - the device and features).

After reviewing the video offered to your attention, you can learn about more economical ways to heat your home.