Circulation pump for heating: selection and installation

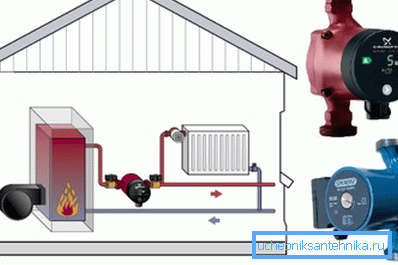

How does the typical circulation pump for the heating system? What are the signs to choose this device? How to install it in the system? Let's try to answer these questions.

Classification

Household circulation pumps for heating their device is not very different from other pumps for pumping low-contaminated liquids: the impeller (usually centrifugal) is responsible for creating the hydraulic head; torque generated by an electric motor.

There are, however, a number of signs that allow these devices to be classified.

Wet rotor

Almost all heating circulators used in private homes - with a wet rotor. Actually, this only means that the rotor of the electric motor is immersed directly in the coolant, which provides for the removal of excess heat and lubrication of bearings.

The popularity of this type of device is due to a very attractive set of characteristics:

- They are virtually silent.

- They do not require maintenance (lubrication and cleaning of bearings, stuffing glands, etc.).

- Their thermal protection does not depend on additional automatic devices: it is ensured by the very presence of coolant in the circuit.

- As a rule, circulating pumps for heating systems with a wet rotor have several modes of operation with stepped or continuously variable revolutions.

Just in order not to form a one-sided assessment of this class of devices from the reader, it is worth adding a spoonful of tar to the barrel of honey.

- Thanks to the bearing lubrication system with coolant, the pumps are very sensitive to its composition and purity.. The presence of sand and scale is unacceptable.

By the way: the problem is completely solved by installing a coarse filter in front of the device.

- Belonging to this class, the recirculation pump for heating is mounted only with a horizontal shaft.

Dry rotor

A circular pump for heating with a dry rotor is also often an impeller on a common shaft with a motor; however, here the rotor of the motor rotates in the air.

Hence the features of the units:

- The noise level is above average. Noise is created, first of all, by a separate impeller of the fan that cools the electric motor.

- Thermal protection provides a separate relay. The result is frequent overheating in violation of the inter-turn resistance of the stator during its malfunctions.

- The pump requires maintenance (at least - the notorious lubrication of bearings and packing gland).

- It cannot be mounted with the motor down - simply because the motor housing is leaking and shaft leakage will cause a short circuit in it.

- In addition, devices of this type are usually single-speed.

What are the benefits of using a dry rotor with so many unpleasant features? The fact that the coolant (or any other medium) can have an arbitrary degree of contamination: this will not affect the life of the bearings and the expensive electric motor.

Devices with a dry rotor are several separate subcategories.

Cantilever

This class primarily includes industrial circulating pumps for heating. Their key feature is the installation of the motor and impeller on a common platform (console) with the possibility of independent replacement; herewith, motors of different power and sizes can work with one impeller - it is enough just to keep the alignment during installation.

Note: the impeller is not sitting here on the same halyard as the motor rotor. They are usually connected by flanges.

When installing this class of devices, it is useful to know a couple of subtleties.

- Powerful industrial circulation pumps for heating are mounted on a separate foundation, not connected with the foundation of the building.

- To eliminate minor axial deviations, the flanges of the connection between the motor and the pump shaft are often not rigidly joined together by bolts, but by segments of reinforced rubber (for example, a conveyor belt).

Block

Unlike the previous construction, in a block pump the impeller stands on a common shaft with the motor. The pump only works with one type of motor.

Inline

This circulation pump in the heating system is different in that the inlet and outlet connections are on the same axis, which allows it to be mounted on a straight pipe section with a minimum distance between the flanges (English in - in, line - line).

Selection by parameters

So, we have to do our own hands to mount a heating system with known characteristics (the number and type of heating devices, pipe diameter, etc.).

How to choose the optimal technical characteristics of the device?

Supply voltage

For industrial devices of considerable power, it is 380 volts; for most households - 220. The only advantage of power supply from 12 volts is increased safety in case of damage to the case; the price of this security is the need to purchase an additional converter and to install low-voltage wiring.

Head pressure

If industrial heating systems with pumping circulation require complex hydraulic calculations to determine the need for pressure, then with cottages and apartments everything is simple: the hydraulic resistance of the circuit of any reasonable length does not exceed 2 meters, which fits the minimum value of this characteristic.

Where in the pump label can I find an indication of the pressure created by it?

As a rule, somewhere near the name there are two groups of numbers separated by a hyphen (for example, 25-40). In this labeling:

| Designation | Decryption |

| 25 | Remote control of the pipe to be attached (in this case, 25 millimeters) |

| 40 | Head in decimeters of water column (value corresponds to 4 meters) |

Performance

It can be selected in two ways. The simplest of them comes down to determining the total volume of the heating system and multiplying it by three.

Once again: the pump must drive through all the volume of the coolant three times per hour. With a slower circulation in severe frosts, the difference in temperature between the beginning and the end of the circuit will be too great.

The method of estimating the performance of the total heat output of a heating system is somewhat more complicated.

The calculation formula is G = Q / (1.163 * Dt), where:

- G - productivity in cubic meters;

- Q is the power of the heat source or the thermal power of a separate circuit in kilowatts.

- 1.163 is the heat capacity of water (constant);

- Dt is the temperature difference between the flow and return (the normal value is 20 degrees).

So, for a boiler with a capacity of 16 KW and a 20-degree temperature delta, an output of 16 / (1.163 * 20) = 0.7 m3 / hour is optimal.

Installation

How difficult is it to install circulation pumps for heating systems with your own hands?

In general, there are few subtleties here.

- Power connection is strongly recommended through a grounded outlet.

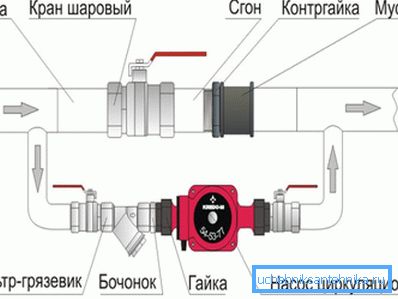

- A coarse filter is placed in front of the pump along the coolant.

- On both sides of the assembly of the pump and the filter on the heating valve is placed - valve or gate valve.

- If the pump is placed in a gravity system and it is supposed to be used with natural circulation in the future, a bypass is left between the tapping points. It is necessarily supplied with a check valve (better - ball).

Useful: if, with the pump running, there is no circulation in the heating system, this most likely means a seized non-return valve. The coolant begins to circulate in a small circle, through the bypass.

Conclusion

We will consider our (albeit somewhat superficial) acquaintance with this type of heating equipment held.

As always, the attached video will offer the reader additional materials. Successes!