Circulation pump for heating selection of the optimal

Any forced heating system includes a discharge unit responsible for the movement of coolant through pipes and radiators. In this article we will look at how to choose a circulating pump for the heating system, because the efficiency and cost-effectiveness of heating largely depends on it. The use of high-quality equipment allows you to reduce energy costs, which in our time is an important advantage.

Basic hardware requirements

Whichever option on the indicators and characteristics you choose, it must meet the following requirements:

| Noiselessness | Due to the fact that this unit works almost constantly when the heating is turned on, the noise level generated during operation is increased. A quality product is distinguished by quiet work and lack of vibration. |

| Efficiency | The level of energy consumption must meet the highest requirements, because the pump runs for days, and the difference in electricity consumption even at 10% will result in significant costs. Instructions attached to the equipment will prompt all the necessary parameters. |

| Reliability | Products of well-known companies have a very large resource, which distinguishes them from cheap analogues. The price of a quality product is much higher, but the service life is much longer. |

Note! It is best to consult with experts about the quality of products of a company, in addition, a lot of information about manufacturers can be found on our resource.

How to choose and install a pump

Due to the fact that there are many modifications of equipment on the market, there is no universal option. The specific model is selected individually for each object, while it should be determined at the design stage, since the characteristics of the system are the basis for all further calculations.

Hydraulic calculation

This type of work is of paramount importance, since it is the correct calculations that guarantee the efficiency of the entire system as a whole and the pump in particular.

At this stage, the following events are held:

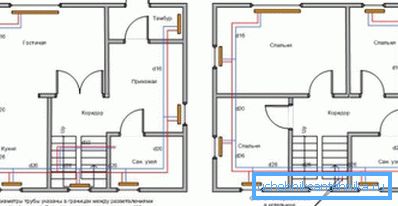

- The selection of the circulating pump for the heating system is the last. The first step is to calculate the length of all laid pipelines, while it is important to take into account their diameter, since the resistance indicators for pipes of different sizes differ very much. As a rule, on liner pipes to radiators a thinner pipe is used, on the main lines - a larger diameter.

- Another important factor is the number of radiators in the system, they also increase resistance indicators.. Their main characteristics can be found in the documents going with the products. As a rule, products from higher price categories have improved characteristics.

- Tees, transitions, corner joints - each of these elements increases resistance, so they must also be taken into account. The more bends and joints in the system, the greater the resistance will be in the end.

- Taps and other valves are counted, their number depends on the features of communications. We note one thing - you should not save on their number, since in case of accidents the circulation in the area is blocked, and repairs can be carried out with minimal costs and problems.

Having on hand all the necessary information, you can make a hydraulic calculation, it is on its result that the selection of the circulating pump of heating depends on it. If you previously had to use complex formulas and seek help from specialists, nowadays there are many programs in which you simply enter the data, and they themselves will carry out all the necessary calculations.

This greatly simplifies the work and minimizes the possibility of miscalculations.

Tip! If the result requires the installation of very powerful equipment, then you should consider using pipes for heating a larger diameter, this will reduce the resistance indicator and allow you to install a less powerful pump, which in turn will save money.

Selection of a specific equipment modification

We will understand what to look for when considering the various options:

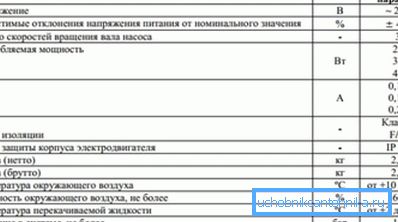

- Marking equipment usually consists of two numbers, as an example, consider option 25-40. The first number indicates the size of the connecting nodes, in our case it is 25 mm or 1 inch, there are also wide variations with a size of 32 mm, larger modifications are mainly intended for industrial use.

- The second number indicates the height of the water rise, in our case it is 4 meters (in terms of the atmosphere, this value is equal to 0.4).

- Energy consumption in different modes of operation - any pump can operate in three performance options. The label attached to the product has all the necessary information on energy consumption, quality options are economical.

- When considering how to choose a circulating pump for heating, we should not forget about such an important factor as the temperature of the fluid in the system. Typically, the maximum figure is 110 degrees, it provides the required reliability and resistance to temperature extremes.

- Another important factor is the equipment management system. This may be a capacitor with a speed switch, or maybe an electronic control unit. The second option is preferable, since it provides a more economical operation of the pump.

Installation

So, how to choose a circulating pump for heating, we figured out, now we note the main recommendations regarding the installation:

- It is best to put it on the return pipe in front of the boiler. This is due to the fact that when installed behind the boiler, the pump can draw water from the boiler too quickly, which is why a vacuum is formed in the upper part of the heat exchanger and boiling is likely. In addition, the fluid temperature at the return is lower, making the pump much longer.

- Before the knot the pump of rough cleaning, and also cranes from two parties is put that in case of need it was possible to make repair and replacement. You can make a circumferential structure (bypass), this will allow you to not interrupt the circulation when the heating pump is turned off.

Due to the fact that all the necessary connecting and sealing elements are included with the equipment, it is quite possible to carry out the work with your own hands.

Conclusion

The choice of a pump with optimal performance allows you to significantly reduce heating costs due to improved heat transfer, because the circulation of the coolant is much more intense. In order to understand the question even better, watch the video, it clearly shows some important nuances.