Collector heating system - the perfect choice for a private

Even at the planning stage of the heating system, it is necessary to make a choice between several completely different methods of supplying coolant to heating radiators. If the budget is not a weak point, the collector system would be an ideal option, and in terms of parameters such as ease of use and durability, it is superior to analogs.

Comparison of collector and other types of wiring

You can choose one of 3 common ways of distributing pipes:

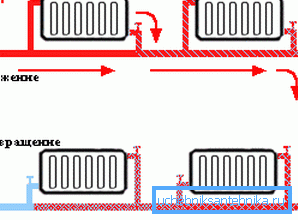

- single pipe heating - ideal for heating a small private house. In this case, all radiators are connected in series, which means that the last battery in the chain works less efficiently than the first one. But the cost of such a scheme is minimal;

- with 2-pipe heating, the wiring diagram can be represented as 2 parallel circuits, one delivers the hot coolant to the heating devices, the second takes the cooled coolant to the boiler. This method of heating can be considered the most common;

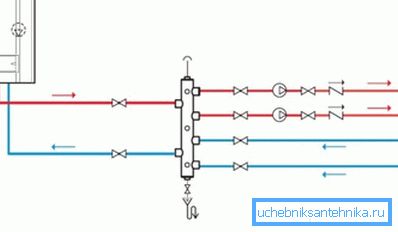

- collector wiring differs from the listed analogs in that each radiator is individually supplied with coolant. That is, a collector is installed in the room (on its device - later in the article), and from it to each battery there is a supply and discharge pipe. This affects the cost, and the complexity of installation, but all the work can still be done with your own hands.

Of course, this is not the best effect on the cost of installation work and materials. The total length of the pipes in this case will be maximum, and the collector also costs money (especially if the model chosen is not the last manufacturer with thermostats).

Strengths and weaknesses of collector heating

There are no ideal solutions in nature, the use of a collector heating circuit is not an exception.

The advantages of a collector heating system include:

- flexibility of the heating system - right on the scallop you can install thermostats, with which the temperature in a single radiator will be regulated;

Note! If necessary, you can simply turn off the battery. The rest of the heating system will function normally.

- since each radiator is supplied with coolant individually, it is possible to use a pipe of small section;

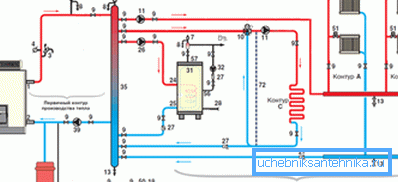

- If desired, you can easily use a combined heating system. That is, divide it into 2 circuits with different operating temperatures, or use a different type of coolant in each of the circuits. For such a solution, you will need a hydraulic needle.

There are collector layout and weak points:

- the increased price has already been mentioned, in addition, if necessary, repairs can be difficult - because the heating pipes are hidden directly under the floor (often they are simply filled with a coupler);

- pipes with such a layout can not be laid along the walls. More precisely, from a technical point of view, this can be done, but then almost half of the wall will be closed with pipes - a dubious addition to the interior;

- collector distribution of heating with small diameter pipes will require a more powerful circulating pump, because the hydraulic resistance will increase;

- It is impossible to call such a heating system fully autonomous — in any case, electricity will be needed — to operate the pump. Natural pressure is not enough to circulate the coolant.

Device and principle of operation of the collector heating system

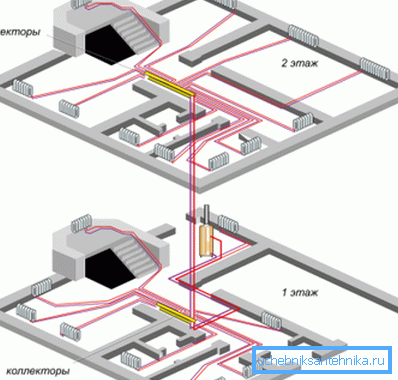

According to this scheme, it is possible to organize not only heating using radiators, but also, for example, to organize a “warm floor” in the room - that is, to do without batteries at all. But in general, the heating system remains unchanged and works on the same principle.

Types of collectors

Collectors can be used for:

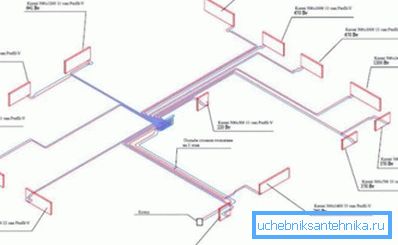

- organization of traditional heating (using radiators). It is possible to combine radiators in groups of 2-3 pieces to save pipes and ease installation;

- heating on the principle of "warm" floor;

- to separate one circuit to 2 or more. In this case, the boiler serves as an energy source for both circuits, but the temperature of the coolant in them may differ significantly (they may even use different types of coolant).

The collector scheme of heating with the use of a “warm floor” is characterized by increased resistance, therefore, an additional circulation pump may be needed for the heating system. Manifold locker is best placed in the center of the house, with this arrangement, the length of pipes for heating different rooms will be about the same.

Another essential element in such a scheme will be a mixing unit in which the temperature of the coolant will drop. At the outlet of the boiler, the water heats up to about +90? C, and in floor heating systems, the temperature of the heat carrier should be about +40? C.

Elements of the collector heating system

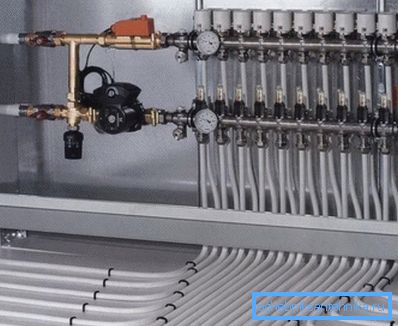

As a rule, all elements are hidden in a separate small locker, and it is located in an inconspicuous place near the wall. The pipes run under the floor, so that the interior of the room is not disturbed.

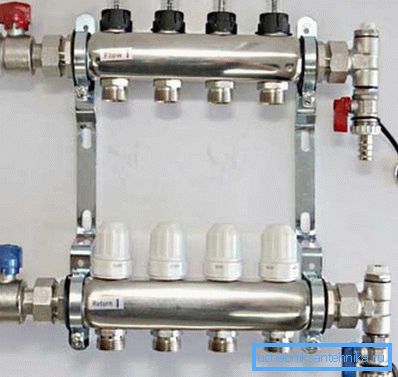

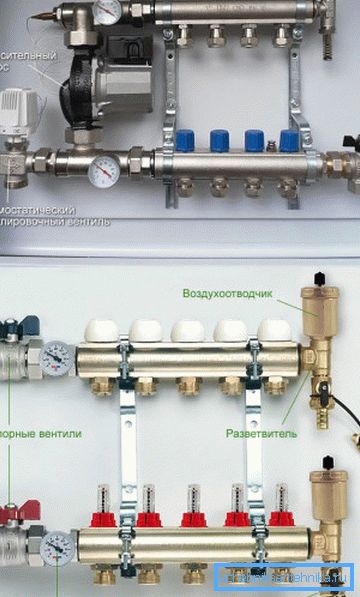

The main element is a comb (needed in the amount of 2 pieces). Externally, the comb (or comb) looks like a simple pipe section, to which several taps are welded (in purchase models, usually the number of taps is between 2 and 12).

Note! If necessary, purchased combs can be connected to each other. So you can create a comb for any number of outputs / inputs.

Collector heating systems, as a rule, are equipped with flow meters and thermostats - compared with the total costs, the cost of these devices is not so great. Purchased scallops are equipped with devices for thermoregulation and water flow measurement at the factory, so just select the appropriate model.

Flowmeters are installed on the feed comb, as the comb must be equipped with air valves to bleed the air - it is useful for removing air from the heating system. On the comb, which receives the cooled coolant, thermostats are installed

Features of the work and the location of individual elements

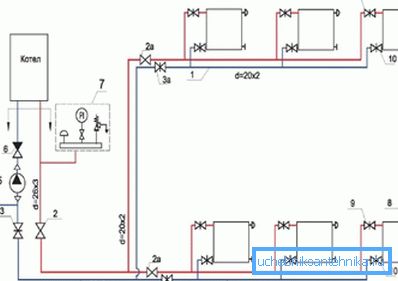

The heat carrier heated by the boiler enters the main feed pipe comb and enters the radiators through individual pipes. In order to ensure the same heating of all heaters, it is recommended to use pipes of approximately the same length and diameter. After that, the cooled coolant flows through the discharge pipe to the second manifold comb and flows back into the boiler.

The installed thermostat controls the water temperature and, if necessary, increases / decreases the coolant current through the radiator, so the temperature in the room is regulated.

Collector heating will work stably only under certain conditions:

- It is necessary to install an expansion tank, this will compensate for the increase in the volume of coolant during heating.

Note! The minimum volume of the expansion tank must be equal to 10% of the volume of coolant in the heating system.

- the circulation pump is located on the return;

- The optimum place for the expansion tank is the pipe section in front of the circulation pump.

Installation of collector heating system

Conventionally, the entire installation process can be divided into 3 stages: laying and fixing pipes on the floor of the room, installing a collector box and connecting pipes to the combs.

Instructions for performing work looks like this:

- the base is prepared first - the concrete is cleaned and leveled;

- then a layer of waterproofing is spread, and a tape is glued along the perimeter of the room, which will smooth out the expansion of the concrete screed;

Note! If the floor in the room is wooden, then the pipes can be simply put under the boards, this will greatly facilitate the work.

- then follows a waterproofing layer;

- over it the usual metal gauze is laid and pipes are fastened to it with wire or special clips. When attaching pipes to the wire mesh, a small gap should be left;

- then follows the fill of the floor. With this method of laying pipes, during transportation of the coolant to the radiator, they will partially work on floor heating in the room.

As for the collector cabinet, then for a private house, you can choose either wall-mounted or floor-standing models, as well as options built into the wall. In principle, this does not affect the heating efficiency in any way, so one has to choose rather on the basis of the convenience of access to the collector combs.

Under the model of lockers built into the wall, it is desirable to provide a niche at the design stage of the house. Regardless of the type, the locker must also be attached to the walls with anchors or self-tapping screws (in a wooden house); for this, special eyes are provided in the design of the locker.

Manifold Comb

Selecting a suitable comb for collector heating is easy. The device is simple, so you need to pay attention, first of all, to the case material.

Purchased devices can be:

- with the steel case and branches;

- with cast iron housing;

- with plastic case.

Preference should be given to molded dies, even in the case of a significant pressure drop, the housing will not let flow. As for the connection of the supply and return pipes, even in the simplest models, the outlets are threaded, this greatly simplifies installation.

Collector heating can be organized without purchased combs, 2 options are possible:

- with the use of welding - from the point of view of economy is very controversial option. Firstly, not everyone knows how to work with a welding machine, and secondly, the quality of the seam cannot be guaranteed. In case of incomplete leakage guaranteed. In addition, it is necessary to buy the missing reinforcement, as a result, the savings will be scanty;

- Well, the most budget option is from the PP pipeline. In this case, the comb resembles a series of tees connected in series with a plug at the end. From the tools you need only a device for soldering PP pipeline. Such a collector will have all the weaknesses of the polypropylene pipeline, in particular the decrease in strength at high temperature coolant.

Summarizing

The collector heating system can be called ideal in terms of efficiency. Independent supply of coolant to each radiator allows you to achieve the ideal microclimate in each room of the house. Large, compared to traditional heating schemes, the cost is somewhat holding back the growth in popularity of this type of housing heating, but if the budget allows, heating using a collector scheme is ideal.

The video focuses on the design of the comb.