Condensing heating boilers and their features

Recently, the owners of houses and cottages when choosing heating equipment increasingly prefer gas condensing boilers. These devices are highly efficient and cost-effective, and also have some other advantages. Below we take a closer look at the device and the feature of these devices.

Principle of operation

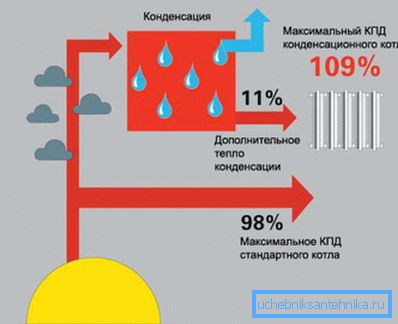

As is known, conventional gas boilers do not fully utilize the potential of the energy carrier, i.e. gas, so their efficiency at best is no more than 80 percent. This is due to the fact that some of the energy is simply thrown out through the chimney.

However, not so long ago, a technology was introduced into gas boilers that allows an increase in efficiency over 100 percent. The essence of this process is as follows - since the combustible mixture contains some steam during combustion, part of the heat goes off with this steam, and so, to prevent its loss, this steam is condensed.

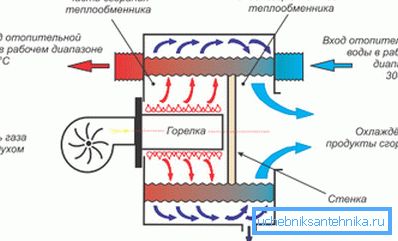

This process allows you to use the resulting hot water to heat the coolant. Hence the name of the boilers. The condensation process takes place in a heat exchanger, which is slightly larger than in a conventional gas boiler.

The heat generated by the complete combustion of the fuel unit, taking into account the vapor released by condensation, is called the “higher” calorific value. Accordingly, the “lower” heat of combustion is called the heat generated by the combustion of fuel without condensation.

As mentioned above, condensing gas heating boilers were invented not so long ago, however, the condensation technology was invented more than 100 years ago. This delayed application is partly due to the fact that only in our time technological progress has allowed the use of available alloys that are not subject to corrosion, as well as to implement other design solutions.

Features of condensing boilers

Merits

Due to the higher efficiency than conventional gas boilers, condensing units are more economical (approximately 15-20 percent).

In addition, they have many other advantages, which are listed below:

- Equipped with more advanced burners that prevent incomplete combustion of fuel.

- Exhaust gases release significantly less harmful substances.. In addition, the temperature of the exhaust gases rarely exceeds 40 degrees.

Due to this, for such boilers you can use a plastic chimney and thereby save on the device of this design. The only thing to be borne in mind is that not every plastic is suitable for this purpose. Therefore it is necessary to use special pipes.

- As a rule, manufacturers of these devices pay special attention to their design.. As a result, boilers look attractive, in addition, it is not difficult to choose a model that fits well with the interior of the room.

- Ability to adjust the minimum temperature of the coolant to 30 degrees. True, such a low limit is rarely required.

- Much longer service life than conventional machines with the same loads. This is due primarily to the use of the most advanced technologies in the manufacture of these devices.

- Noiselessness at work.

- Simple instruction manual.

As a result of these advantages, such devices have found particular application in the West, in particular in Germany, according to statistics, more than 30 percent of all gas boilers are condensing. And in some countries, the use of conventional gas appliances is even prohibited.

Gradually, these boilers are becoming popular in our country.

disadvantages

Of course, along with the advantages, like any other equipment for heating, these devices have some of their drawbacks:

- High price - condensing devices are at least twice as expensive as traditional devices.

- They require special calculation of the heating system for a lower coolant temperature (not more than 70 degrees). The need for a lower temperature inside the system is dictated by the need for condensation.

- The need for arranging a special conduit to drain accumulated liquid to the outside. With constant boiler operation, the volume of liquid can reach 30 liters per day. Most often, water is discharged into the general sewer system.

- Professional equipment is required to install and maintain this equipment.

- The need for electricity, which is characteristic of almost all modern gas boilers.

Design features

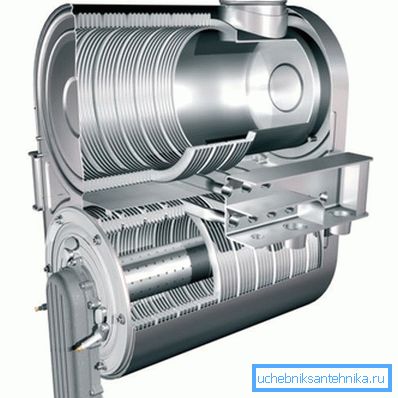

One of the main distinguishing features of condensing boilers is the heat exchanger. It is made in the form of tubes with a complex cross-section, which is necessary to increase the volume of the structure and, consequently, increase the efficiency of the apparatus.

In addition, it is different and the material of the heat exchanger, which, as already mentioned above, has good resistance to the negative effects of various acids. Most often, this material is silumin or stainless steel. This is due to the fact that the effective formation of condensate occurs precisely due to the high acidity, which causes corrosion of many metals.

Before the burner a fan is installed, the task of which is to suck gas from the gas pipeline and mix it with air. After that, the combustible mixture is sent to the burner.

All processes of operation of the device are controlled by electronics, including it optimizes its power, as a result of which the gas and electricity consumption (consumed by the pump) is reduced.

Note! The efficiency of the apparatus depends largely on the parameters of the heating system. For example, at low coolant temperature, condensation will occur more efficiently, so in the return circuit the water temperature should not exceed 60 degrees Celsius. In this case, the efficiency of the boiler will be much higher.

It should be noted that initially condensing boilers were manufactured as dual-circuit boilers, however, single-loop models currently exist. They are not able to provide hot water in the house, but they are a bit cheaper.

In addition, all existing devices differ in the method of installation:

| Outdoor | Represent units of 100-120 kW. Used for heating office and industrial premises. |

| Wall mounted | Devices with a capacity of 30-40 kW - are used in autonomous systems of heating homes and apartments. |

Tip! To ensure hot water supply, you can connect the boiler to the single-boiler.

To connect these devices, you can purchase special kits, the list of which includes:

- Broad tanks;

- Safety devices;

- Piping kits;

- Systems for removal of combustion products, etc.

However, in any case, install the device with your own hands will not work, so all work must be performed by qualified specialists.

Here, in fact, all the main features of the gas boilers of the new generation.

Conclusion

As we found out, condensing boilers have a number of advantages, and the main one is fuel economy, which reduces heating costs. However, in our country, these devices are not yet very common, due to their high cost. But this, as they say, is a matter of time.

From the video in this article, you can get more information on this topic.