Connecting bimetallic radiators. comparative characteristics

The connection scheme of bimetallic radiators of heating does not have significant differences from other types of heaters, so we will discuss the general rules for installing batteries. In this case, we note some nuances and features, and tell you how to connect a bimetallic radiator of heating.

Bimetallic heating radiators

Comparative characteristics with other types of batteries

First you need to understand what kind of heating radiators are, and how they differ from each other.

We list the main types:

- Cast iron batteries - One of the most common types, which is found in most apartments of Soviet construction. It is a system of connected cast iron sections with rather thick walls and a large mass. It is characterized by high strength and durability, however, it has low efficiency and heat transfer, as well as a large thermal inertia;

- Steel tubular registers - it is a system of pipes of a sufficiently large diameter, or one pipe in the form of an S-shaped bend (for example, a heated towel rail). This type of equipment is usually installed in large rooms - concert halls, cinemas, sports complexes, supermarkets. Differ in high power and large volume of coolant;

- Steel heating panels. They are welded profiled plates of steel, inside of which there are channels for the circulation of coolant. They have a rather low resistance to hydraulic shocks and low strength, are susceptible to corrosion and are not very reliable;

- Aluminum radiators - A more modern type of battery, which is characterized by increased heat transfer and efficiency, low heat carrier volume and low mass of the device. Due to the low thermal inertia, it lends itself well to automatic and manual temperature control. Demanding on the quality of the coolant and its acidity, have an average strength and service life;

- Copper batteries - are a system of tubes with plate fins. They are distinguished by the highest heat emission and efficiency, high durability and resistance to hydraulic shocks, lack of corrosion and long service life. The only drawback of copper units is the high price;

- Bimetallic radiators externally and in design they resemble aluminum devices with the difference that the inner walls of the channels are made of steel or copper. Thus, it is possible to increase the efficiency and heat transfer of the battery, but to preserve its strength and durability.

To understand the main distinguishing feature of a bimetallic device, it is necessary to better understand its design. The main task of any liquid-cooled battery is to ensure maximum heat transfer from the coolant to the environment, while having an adequate supply of mechanical and corrosion strength for long-term efficient operation.

The degree of heat transfer is directly dependent on the thermal conductivity of the metal and the wall thickness. The most heat-conducting materials are aluminum and copper, therefore the most efficient devices are made of non-ferrous metals.

On the other hand, steel and ferrous metals demonstrate the highest strength. But they are prone to corrosion and have a low thermal conductivity. At the same time, steel is much cheaper than copper and aluminum, which is also an advantage.

The design of a bimetallic radiator is characterized in that the inner walls of the channels are made of durable corrosion-resistant steel or pure copper, and the outer walls and fins are made of lightweight and heat-conducting aluminum. This decision made it possible to combine the advantages of steel and non-ferrous metals in one device.

Note! Bimetallic radiators combined the advantages of products from ferrous and non-ferrous metals, becoming the most progressive and modern type of heating devices.

Advantages and disadvantages

Consider the positive and negative aspects of the use of aggregates with combined metals in the composition. Let's start with the benefits:

| Advantage | Description |

| High mechanical strength | The core of the device is made of high-strength anti-corrosion steel, which is able to withstand a working pressure within 40 atm., Significant water hammer and external mechanical effects. |

| Durability | The service life of this type of battery is from 20 to 50 years. This is achieved by high build quality and the use of the most suitable materials. |

| High heat emission | The thermal conductivity of aluminum is four times the thermal conductivity of steel, and copper is twice as conductive as aluminum. Heat output of one bimetal section is 150 - 180 W, which is significantly higher than that of single-element models. |

| Lack of electrochemical processes | Since the inner surfaces of the channels are made of steel, like pipes, the system does not produce galvanic processes and electrochemical corrosion. |

| Good adjustment | The units are distinguished by a very small coolant capacity, which, in combination with the good thermal conductivity of the materials, allows effective temperature control through thermostatic valves. |

| Beautiful design | The casting ability of aluminum allows you to create any form of housing, and modern types of paints and coatings make the appearance of batteries particularly attractive. |

The disadvantages of the model include its high cost and requirements for the quality of manufacturing and assembly. It is necessary to combine materials with strict performance of technology, otherwise the device will serve not for long and will not meet the listed criteria.

Note! Bimetallic convector can be attributed to the most successful and progressive types of heaters.

Wiring diagram for radiators

The connection of bimetallic radiators is performed according to the same rules as for other types of batteries.

Consider the standard strapping schemes:

- Diagonal connection. The supply pipe enters the upper opening, and the return pipe comes out of the lower opening on the other side. It is considered the most effective way to ensure fully uniform heating and maximum heat transfer;

- Side connection. The supply pipe enters the upper opening, and the return pipe comes out of the lower one on the same side. With the number of sections up to 12, there is practically no difference from the diagonal type, but with the increase of this number it is significantly inferior;

- Top connection. The feed enters the upper opening on one side, the return flows from the upper opening on the reverse side. Enough effective way;

- Bottom connection. The input and output of the coolant through the lower holes on both sides. Warming is less uniform and less effective;

- Connect to one point. Only one pipe enters the device. The method is the least effective and is rarely used.

It should also be remembered that there are single-pipe and two-pipe heating systems. Although, in terms of strapping radiator - it is not so significant. Most house wiring is single tube type.

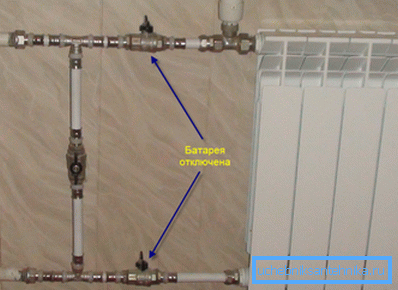

Note! In monotube systems for normal adjustment and maintainability of devices they should be connected via a bypass.

Radiator installation

For those who decided to install a radiator with their own hands, we have prepared an instruction.

We will consider a one-pipe system with lateral connection:

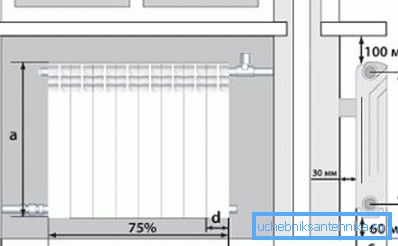

- According to the manufacturer's scheme, we mount the mounting brackets;

- We carry out assembly of the battery of heating. Screw the Mayevsky valve into the upper hole, and the plug in the lower one. In the other two we screw in the shanks of the shut-off and adjusting cranes, the adjusting - from above;

- We hang and fix the battery on the wall;

- Screw the thermostatic valve into the supply pipe and connect it to the shank installed in the battery hole;

- In the return pipe, we install a shut-off ball valve, which we connect to the shank installed in the lower hole;

- The supply and return pipes are connected via a bypass, on which we also install an adjustment valve.

Note! Use only high-quality couplings and adapters, good shut-off and control valves. Normal fittings are made from plumbing brass.

Conclusion

Bimetallic heating radiator is a great choice for heating a modern apartment or country house. The devices are characterized by high performance, and the video in this article will help to understand the rules of their installation.