Connecting the gas boiler to the heating system -

Heating gas boilers have gained immense popularity among developers due to a number of advantages: high autonomy of the system, it is able to work without intervention for a long time; ease of use; minimal maintenance cost and high reliability; ease of adjustment and the ability to set a certain temperature.

The correctness of the equipment connection is very important, because the efficiency and safety of the system largely depends on this, and this is the kind of work we will consider in this article.

Main stages of the workflow

To make it easier to understand, we will divide all the work into several stages. They are presented in the order of their execution in accordance with the technology.

| Boiler installation | First of all, you need to install the unit, it can be both floor and wall. Each option has its own distinctive features, which will be discussed in detail in the next chapter. It is important that the place and method of installation comply with safety requirements. |

| Connecting the heating circuit | This type of work includes the connection of the output and return lines, along which the coolant will move through the system. The works are quite simple, however, it is important to follow the accuracy and ensure the best quality of connections. |

| Water connection | Most models of heating equipment are designed for a constant supply of the system from the water supply system; therefore, it is important to foresee the pipework in advance for this type of work to take the least time. |

| Gas connection | It is not necessary to explain the importance of this stage, because everyone knows how dangerous gas leaks can be. The work is carried out with special care so that the results meet the highest requirements of reliability and safety. |

| Verifying performance and system startup | After installation, it is necessary to check the tightness and reliability of all connections. In addition, the first launch must be carried out in the presence of specialists of the supervisory organization, it is they who put the system into operation and give the appropriate permission to use communications. |

Note! Whatever type of work you do, you should use only high-quality materials and components, it guarantees the reliability and durability of the system, because even properly conducted activities do not guarantee a good result if low-quality parts and components are used.

Features of the work

Consider the stages in more detail, since each of the types of work in its own way is important, and violations at one of the stages will entail problems throughout the system. Even before starting work, you should stock up with the necessary tools and materials so that later there will be no downtime due to the lack of certain elements.

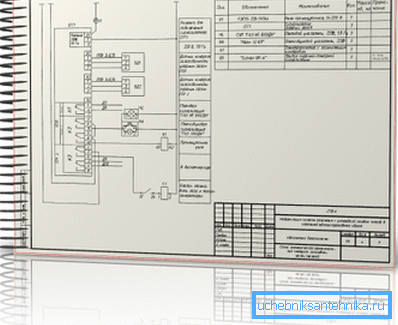

It is easiest to calculate the required number of certain elements for a project, which must necessarily be developed and approved by the supervisory authority even before the start of work; its absence can entail many problems, including reworking all communications.

Boiler installation

Installation of equipment involves a number of activities:

- First of all, the required power unit is purchased. You should not buy too powerful equipment, as there will be gas overspending, besides its price will be noticeably higher.

- If a floor boiler is used, then a special room must be present in the building. If it is a private house, then an extension is often done or a room in the basement is allocated. To ensure the required level of security, the boiler room must be equipped with a window and a high-quality ventilation system, which can be either natural or forced.

- It is very important to prepare a site for the installation of the boiler, it should be even, some manufacturers recommend concreting the legs of the equipment with a thin layer of mortar to ensure its immobility during operation. It is worth noting the fact that the boiler can be located below the floor level by 20-30 cm, this saves space.

- Connecting the wall gas boiler to the heating system begins with its mounting on the wall. For this purpose, special brackets are used, which are most often included in the kit. It is very important to ensure the strength of the mount so that the equipment is stationary, otherwise it may fall, which will damage all connections and create an emergency.

- When mounting a wall-mounted boiler, it is important to take into account certain requirements: it should be located on a vertical surface, the distance to the ground should be at least 80 cm, and no other device should be located closer than 50 cm, including meters. These are very important requirements that are checked first by the regulatory authorities.

Tip! If the device of the chimney and high-quality ventilation system is difficult, then the best option would be to use a turbocharged gas boiler. He has air exchange through the turbine, which is displayed through the wall, so that the workflow is much simpler and cheaper. Such boilers are the ideal solution for those who do not want to build a chimney.

Connection to the heating circuit

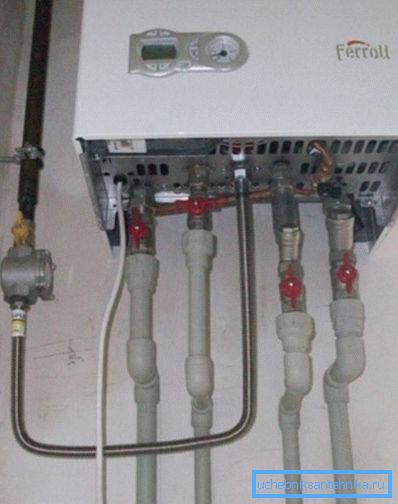

After the boiler is installed, you can proceed to the next stage. It should be noted that most models of equipment, regardless of the manufacturer, have a standard arrangement of nozzles:

- In the center is the site of accession to the pipeline.

- Elements of hot and cold water supply are installed on the right and left.

- At the edges there are branch pipes designed to connect the heating system, and, when viewed from the front, the return line will be on the right and the hot coolant supply to the circuit will be on the left.

Connection of supply and return of the coolant is made taking into account the following requirements:

- All connections must be tightened very carefully, but you shouldn’t be too zealous, as the thread may be damaged and all connecting elements will have to be replaced.

- In order to prevent leaks in the future, all connections are sealed. If before the main sealing material was tow and paint, then in our time there have been many special seals for threads that are resistant to high temperatures. With their help, you can make reliable connections with your own hands.

- Another very important element that should not be forgotten is the coarse filter installed on the return line. It retains all solid particles and prevents them from entering the boiler, thereby protecting the equipment and significantly prolonging its life.

- The last important element is the taps installed before the connection. With their help, if necessary, you can turn off the water supply and repair equipment. The lack of shut-off cranes complicates repair work and may cause system airing.

Water supply connection

As noted above, almost all modern equipment models require connection to the water supply network. This allows you to provide a constant feeding system and eliminates its work without the necessary level of coolant.

Regarding this type of work, the following can be noted:

- The works are in many ways similar to the connection of the heating circuit, with the only difference that the elements of a different diameter are used, respectively, and the valves are used differently.

- The cold water supply must be equipped with a filter for water purification, as its quality, especially in city water lines, leaves much to be desired. The easiest way to use a system with replaceable elements, this is the most budget option, while its effectiveness is very high.

- All cut-off valves are recommended to be fixed through the “American”, so called special detachable connections. Using this option allows you to quickly replace broken valve elements.

Tip! To secure the boiler from scale, it is possible to additionally install a magnetic magnetic filter on the supply pipe. It helps to get rid of metal particles in a liquid, due to which the scale formation rate is significantly reduced and corrosion processes on metal parts are slowed down.

Gas connection

This part of the work is the most responsible due to the increased danger of gas pipelines. Any mistakes can lead to disastrous consequences, because gas when released into the air creates an explosive mixture.

Works are performed as follows:

- A valve should be installed at the gas outlet to shut it off; this part of the work is done by the gas workers, you only need to specify where to bring the pipe.

- Next, a special filter is installed, it is better to choose a quality product so that cleaning is carried out at the highest level.

- It is joined by a special flexible eyeliner, which is first attached to the filter. As a sealing element it is necessary to use tow and paint, since other materials do not guarantee the required level of tightness. Best of all proven products made of stainless steel - durable and durable material.

- Accession to the boiler is sealed with paronite gaskets, this material allows for excellent tightness.

System check

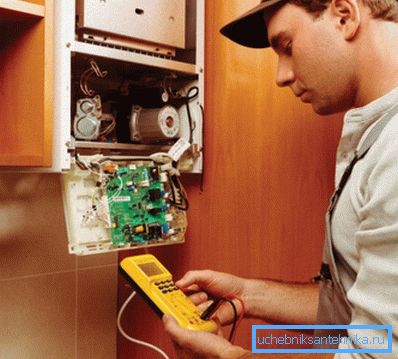

After the connection to the heating system of the gas boiler is completed, it is necessary to carry out another important measure - check all connections for leaks.

There are several important features:

- The reliability of all liquid communications is checked first of all by test filling the system.. The equipment does not turn on, just all the interfaces are examined for leaks. Even the slightest humidity suggests that the connection is made poorly and should either be tightened or altered altogether (in cases where the thread is damaged).

- Gas connection is checked differently: the valve is opened, and all connections are treated with a solution of soapy water. Even the smallest leakage will be clearly visible, as bubbles will form. Specialists have control devices, but simple soapy water is a no less accurate indicator of tightness, because this method has been tested for decades.

- The first launch of the heating equipment is carried out with the obligatory presence of a specialist from the supervisory authorities of the gas equipment. If you start the system yourself, you may have problems with commissioning and obtaining permission to use communications.

Conclusion

To connect the gas boiler, it is necessary to carefully study the recommendations of the supplier of equipment, as well as take into account all the requirements of supervisors, the only way to ensure the health and safety of the system.

We recommend to watch a video in which some important points of the process are explained in more detail and are shown visually.