Connection scheme of a solid fuel boiler to the heating

Any equipment, no matter what category of complexity it belongs to, requires a serious approach to installation and subsequent operation. Otherwise, the uninterrupted operation period can be noticeably reduced. Adhere to certain rules is also necessary when connecting a solid fuel boiler, despite the simplicity of the design.

Installation Features

Being engaged in the installation of such equipment, you should follow the basic rules that will allow the device to operate as safely as possible.

Before starting work, you need to make the calculations necessary to determine the technical parameters of the device, as well as to find the right place.

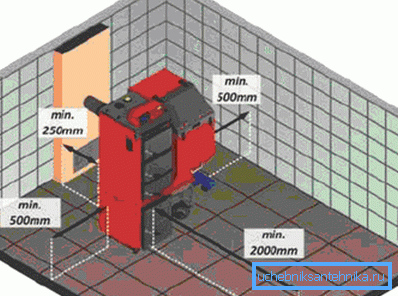

- The unit operating on solid fuel must be in a separate room of at least 7 square meters. m

- In the boiler compartment, it is imperative to create forced ventilation: for 1 kW of appliance's power should be 8 square meters. see ductwork.

- The floor covering should be chosen taking into account fire resistance, and a sheet of metal should be placed in front of the boiler.

- The device should be located at some distance from the side surfaces: at least 200 cm from the front and more than 50 cm from the side walls.

Attention! During the work, metal pipes should be used to connect solid fuel boilers to the pipes. Their length should not be less than 15 cm.

Installation process

Installation is not very complicated, which means it can be carried out by hand. Further, it is recommended to familiarize yourself with the main stages that will have to go through in the process of installing the heater. With proper installation of the heating system will serve for many years.

Foundation preparation

Regardless of the used scheme of connection of solid fuel boilers, the supporting structure on the floor is prepared in the room. Usually it rises above the main part of the lower plane by 10-20 cm. The most popular option is a reinforced screed made of concrete.

It is recommended to lay a metal sheet on the surface of the podium to protect against thermal effects. As an alternative, asbestos plates with a minimum thickness of 5 mm can be used.

Strapping device

When organizing a system, special attention should be paid to the selection of the most efficient mode of operation and temperature adjustment. If the strapping is carried out correctly, it is possible to save money, since the thermal energy in this case is optimally distributed.

When installing can be used one of several schemes.

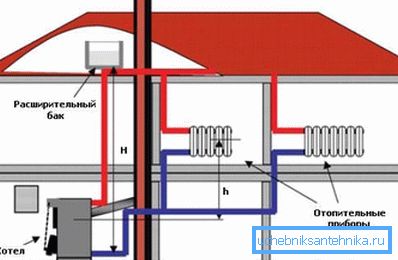

- Strapping in the heating system with natural circulation is the easiest option., since it does not imply additional accessories. All adjustment is done manually, fuel is added as it burns. Such a scheme assumes the presence of pipes with a large diameter.

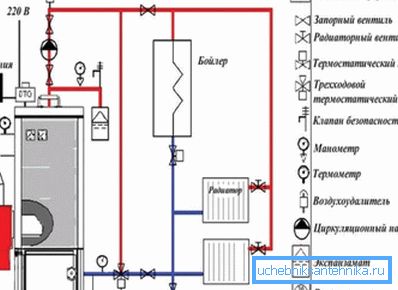

- The system with forced circulation must necessarily include a special pump for pumping fluid. With it, the coolant moves evenly along a closed loop. Thanks to this device, it is possible to adjust the heating radiators separately. However, electricity must be present in the building to operate the circulation pump of the heating system.

- Collector wiring is considered the most difficult, due to the presence of a large number of different devices - valves, air extractors, valves, taps and other devices to control the required parameters. The price of such a heating network is quite high.

- Ring piping with primary and secondary circuits is used, as a rule, in residential buildings with many consumers. When the device requires the installation of several devices at once for the organization of the circulation of the coolant.

Note! Solid fuel units for heating that are dependent on electrical energy must be equipped with emergency circuits, so that when the light is turned off, normal work continues.

Creating a chimney

The devices are equipped with a pipe for removal of combustion products, the cross section of which must correspond to the size of the outlet located in the upper part. The most commonly used ready-made elements, consisting of metal inserts and insulating material.

In the ideal version, the chimney should not have turns, but if they are still present, they should be made as smooth as possible. All joints between components of the pipeline must be sealed so that the smoke from the boiler does not penetrate into the heated room. For these purposes, can be used heat-resistant tape or a special composition.

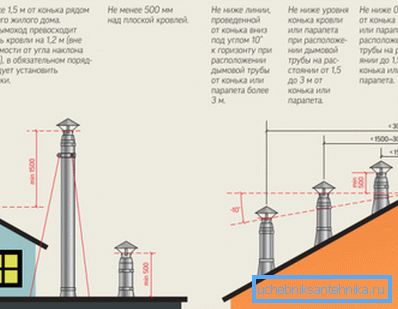

Particular attention should be paid to the release of the pipe above the roof, since the quality of the thrust will depend on this.

- If the distance from the ridge to the chimney does not exceed 150 cm, then you need to make a release above the highest point by 50 cm.

- When moving away from the intersection of slopes up to 300 cm, the pipe should be displayed so that the upper part is flush with the ridge.

- If the chimney is at a decent distance, it should be located below the top of the roof with an angle of no more than 10 degrees.

As a conclusion

After the instruction has been studied, many individual developers will understand how to connect a solid fuel boiler to the heating system of a residential house. The choice of the final scheme will depend not only on the preferences of the owners, but also on the operating conditions, because in some cases one has to go for some costs. Other important consumer information is included on the video.