Copper radiator: features of choice and operation

The main characteristic of any heating radiator is its heat transfer, this parameter is responsible for the efficiency of space heating. Earlier, only iron or steel was used for the production of batteries, later aluminum, bimetallic and even copper radiators appeared. To date, the choice is increasingly to buy aluminum or copper radiator, steel and cast iron models have lost some popularity.

Features copper heating radiators

Each type of radiator has its own characteristics:

- steel - they are characterized by high strength, besides, steel is a rather ductile material, so that even shock impacts are tolerated without problems. On the other hand, the thermal conductivity of the material is average, and the problems of corrosion have not gone away. However, given the low cost, this is an acceptable option for a budget heating system;

- cast iron batteries - the main difference from steel is that such heaters are more massive. Pig iron is fragile, but under normal operating conditions it can last for more than a decade;

Note! Regardless of the type of radiator used, the quality of the coolant is of great importance. Only if it is clean and free from impurities can we hope for a long and stable operation of the heating system.

- a little later appeared aluminum and copper radiators, non-ferrous metals began to be used because of their greater thermal conductivity. Such a battery warms up quickly and even with small sizes is very effective;

- in order to reduce the cost can be applied and combination of different materials. For example, steel + aluminum or copper + aluminum. In this design, radiator copper pipes are used, but the fins are made of aluminum plates. Due to the heat conductivity of copper, it is possible to ensure high heat transfer to the ribs even with a small tube diameter.

If cost is chosen as the main criterion, then steel and cast iron radiators are the leaders.

But if finances are not a weakness, then it is possible to dwell on copper radiators, in addition to high thermal conductivity, the use of such batteries will allow:

- do not worry about corrosion, copper does not rust;

- increase the operating temperature of the coolant. In an autonomous heating system, it is quite possible to use the working temperature up to the mark of 100-150? С. In general, the upper limit of temperature is considered to be 250? C;

- copper is a soft metal, so even in an emergency when water freezes in the system, there is a possibility that the metal will not break, but is just slightly deformed;

- the working pressure in the system can be safely raised to 15-16 atm;

- The advantages include the fact that copper is resistant to hydraulic shocks, this is due to the ductility of the metal.

Among the shortcomings, we can only note the cost, the price can easily exceed 10,000 rubles.

Read more about copper radiators

Given the cost of a copper battery, it is worthwhile to find out more about whether such expenses are justified. Yes, and bright advertising manufacturers may be a little confused.

Understand the terms

The main mistake of most materials on copper radiators is that such concepts as thermal conductivity, heat capacity, and heat transfer are used as synonyms. In fact, these are completely different battery characteristics.

Heat conductivity of metal depends on heat conductivity. In the case of batteries, this parameter is not particularly critical, a couple of minutes will not play a special role. The inertia of the heater depends on the heat capacity, but the heat output is responsible for how effectively the battery heats the room.

That is why it is difficult to unambiguously answer which radiator is better than aluminum or copper. Both are good, just copper reaches the operating temperature much faster than the aluminum counterpart.

Note! A massive cast-iron battery will cool much more slowly than a thin-walled bimetallic one. That is, the cast-iron radiator has greater inertia.

In the case of heat transfer, much depends on the area of the fins and the metal itself. And here aluminum is comparable to copper.

That is why copper-aluminum radiators are so popular. They cost less than fully copper, but they are not much inferior to them in terms of efficiency.

In general, the question of comparing different types of radiators is quite subtle. Therefore, when choosing, it is worthwhile to focus on the thermal capacity of the section and such parameters as operating pressure in the system, coolant temperature, etc. All these characteristics are indicated in the documentation for the heating radiator.

Types of copper heating devices

The principle of the classic cast iron battery is that the water passes successively through all sections, the metal is heated and due to heat transfer from the surface of the battery the room is heated.

Copper heating radiators are arranged a little differently, such options are possible:

- on the tube there are ribs in the form of flat plates. The coolant, passing through the supply pipe, heats the fins of the radiator, and they give off heat to the room;

Note! Externally, this design does not look very nice, so the design is closed on top with a decorative casing with slots for heat transfer.

- can also be used registers of copper tubes. In this case, heat is transferred from the surface of the pipes through which the coolant passes, so that the copper consumption is greater than in the first construction.

Features of the selection and operation of copper radiators

The choice in favor of a copper heater puts forward a number of requirements for the heating system:

- increased requirements for the quality of the coolant. In particular, the presence of solid particles in the water is unacceptable. Over the years of operation, the soft metal may simply wipe, and a thinner wall may not withstand the working pressure in the system, repair of copper radiators in this case is impossible;

- if copper batteries are installed in the apartment, then the pipes, as a rule, are also copper. If not, then it is necessary to take into account the compatibility of metals in the choice of valves. In particular, it is undesirable for copper to come into contact with steel; as a result of the electrochemical reaction that takes place, the service life will decrease several times.

With regard to the technical side of the issue, the selection is performed on thermal power, and only then the aesthetic side of the issue is considered.

For this you need:

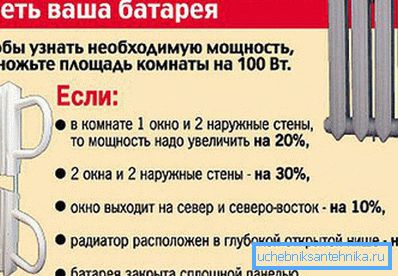

- calculate room area in m2. Further, guided by the average requirement of 100 watts of the heater thermal power per 1 m2 calculate the required radiator power;

Note! The indicated ratio is valid for ceilings with a height of 2.7 m; for a greater height, the result can be increased by about 10-15%.

- In the documentation for the radiator, the heat output of one section must be indicated. Based on this data, we calculate the required number of sections. At the same time, aluminum radiators and a copper heat exchanger will make it possible to choose a device that is significantly smaller in size while maintaining equality in thermal power with more massive steel and cast-iron radiators.

Homemade Copper Battery

Independently produce a full-fledged analogue of the factory radiator is almost impossible. In particular, it will be difficult to perform the fins, while achieving high heat transfer from the heat transfer pipe to the fins. However, you can try to make a register of the tubes.

The effectiveness of such a device, of course, will be questionable (the small surface area is to blame for everything), but the appearance will be excellent. So consider this option is only as an effective filling of an empty niche in the house, the register cannot replace 100% of the purchased batteries.

As for the manufacturing process itself, several general recommendations can be made:

- for the connection of elements can be advised welding. It is undesirable to bend pipes, since this will lead to a decrease in wall thickness, it is not known whether it can withstand the pressure in the system;

- all pipes must be perfectly flat, you can pre-fix them in the tree;

- obligatory check for leaks;

- as a finishing treatment, it is advisable to varnish the pipes, thanks to which the register can be hidden and used as a decoration of the room.

Of course, such an analogue of the battery, created by hand on thermal power will be inferior to the factory batteries. But such things are created more for the love of creativity than because of the cold in the house.

In conclusion

The use of metals with high thermal conductivity has long been adopted by manufacturers of heating radiators. This allows you to increase the heating rate of the heater, and the combination of metals reduces the cost of the battery while maintaining high performance characteristics.

You can even try to create a copper radiator with your own hands, it certainly will not reach the efficiency of the purchased models, but it will look good in the house as an interior decoration.

The video in this article shows a device radiator using copper tubes and aluminum fins.