Correct installation of bimetallic radiators in homes and

In most regions of our planet with a temperate, continental and cold climate, autonomous or centralized water heating systems are considered to be the most efficient methods for heating residential and commercial buildings. As a coolant, they usually use plain water or non-freezing liquid that circulates between the heating boiler and room heat exchangers, which are used by domestic heating radiators.

Independent installation of a domestic heating system

Currently, there are a large number of various household heating appliances made of various materials using advanced technologies, so later in this article we will consider in detail the basic performance qualities of bimetallic room radiators designed for heating residential apartments and private houses with an autonomous or centralized heating system.

Also, for home craftsmen here will be offered a detailed instruction, which presents a step-by-step description of the technology of self-assembly and connection of bimetallic radiators to a domestic heating system.

Design features of bimetallic radiators

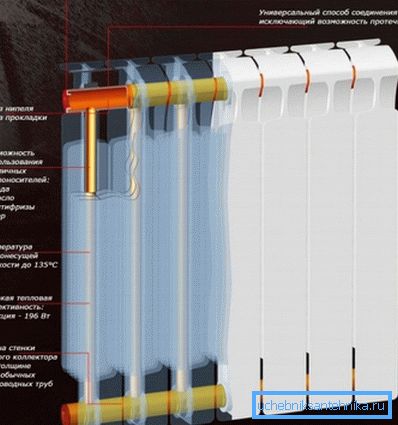

All bimetallic domestic heating radiators are made of two different types of metal, and in most cases are a composite circuit in which the internal trunk collectors and vertical heat-conducting channels are made of steel, and the outer cover and side finning is made of non-ferrous metals with high thermal conductivity.

Another characteristic feature of bimetallic products is that their internal channels have a smaller cross-section compared to the usual cast-iron battery, therefore, with the same pressure and flow rate, a complete change of the total heat transfer volume in them occurs faster, due to which they have a higher heat transfer .

Note! When heating and cooling bimetallic elements, at a certain moment, you can hear the characteristic low-volume clicks. It should be known that they arise due to the difference in the coefficients of linear expansion of different metals, therefore, they are considered normal.

Advantages and disadvantages

The main disadvantage of all bimetallic radiators, compared with cast-iron batteries, is their relatively high price, which is due to the high cost of non-ferrous metals used for the manufacture of heat dissipating side finning elements.

At the same time, despite the high cost, all bimetallic products have a number of undeniable advantages, which are as follows:

- Due to the thick-walled water supply manifold and vertical heat-conducting channels made of steel, such radiators are very reliable, since they do not deform under the influence of high temperature, they resist hydrodynamic loads well, because they are designed for water pressure in the system up to 52 kg / cm ?.

- Structural and tubular steel is less susceptible to corrosion than aluminum., therefore, the inner walls of the pipes practically do not oxidize and do not overgrow with lime.

- Outdoor aluminum fins have a high thermal conductivity., and thanks to a specially designed cross-sectional profile, it has a large outer surface area, therefore, such parts have high heat transfer and good heat dissipation ability.

- Among other things, products with aluminum fins are significantly lighter than cast iron batteries., therefore, installation of bimetallic heating radiators can be carried out independently, without assistance.

- Bimetallic radiators have a long design life, and the outer decorative coating with powdered polyester enamel gives them an aesthetic appearance.

Tip! When choosing a colored bimetallic radiator, preference should be given to models of light, and best of all white, since the light surface has the best heat-radiating ability.

Assembly of heating sections

All types of household radiators go on sale in the form of a finished battery assembled from several sections of heating elements.

Depending on the volume of the heated room, the heat insulating capacity of the bearing walls of the building, as well as the climatic features of a particular region, the dimensions and, accordingly, the thermal capacity of the battery can be changed at any time by disconnecting or adding the required number of sections to it.

- The heating sections are interconnected by means of special feed-through nuts, on which, on the one hand, the right-sided thread is cut, and on the other hand, the left-sided external pipe thread is cut.

- Each section of the battery has a through hole for the passage of water, which also, on the one hand cut right-sided, and on the other hand - left-handed thread.

- Before assembling the battery, you need to lay adjacent sections opposite each other, placing them on a flat hard surface facing down.

- Prepare two feedthrough nuts, put them on one sealing gasket, and then hand-tighten them into the upper and lower holes of one of the sections 1-1.5 turns, paying attention to the correct direction of the thread.

- The threaded holes of the water manifold of the second section should be aligned with the threaded part of the gland nuts, then, as far as possible, wrap them in both sections by hand at the same time, without making much effort.

- Making sure that the radiator sections are in line with each other and in the correct direction of threading, alternately, with a uniform force, tighten both through-bolts with a special radiator key.

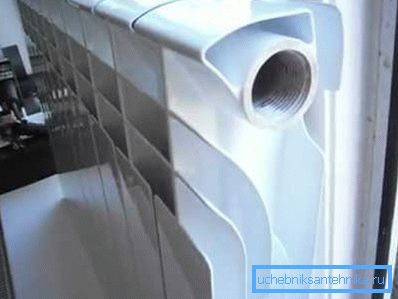

Tip! Modern heating radiators have inlet and outlet threaded holes with a 1 ”thread diameter, and the supply pipes in the house may have a different size, for example, 1/2” or 3/4 ”. In order to join them together, before installing you need to purchase a special installation kit for the existing diameter of pipes.

As a rule, it consists of two or four wall brackets with dowels on concrete or brick, two adapters with right-handed thread, two adapters with left-handed thread, one screw cap and one valve for air bleeding. Also separately should be purchased ball valves and cap nuts American.

Technological features of installation

Independent installation of bimetallic radiators on the wall is carried out using standard fixing brackets, and the connection to the pipes of the heating system is done using a special cap nut, the so-called American.

- Before installing new radiators to the existing heating system, thorough flushing of old communications should be performed to remove debris, rust, and salt and lime deposits from the inner surface of pipes.

- At the end of the supply water pipes of the heating system, cut the threads on which you need to screw brass or bronze tees.

- To install ball water taps in the direct outlets of the tees, and connect the T-shaped outlets of the inlet and return pipes to each other with a pipe segment so as to obtain a bypass pipeline, or in other words, a bypass.

- In the inlet and outlet openings of the radiator, install adapters of the required size, inside which to wrap the threaded connector of an American nut.

- After that, you need to fix the radiator on the wall using brackets from the mounting kit, and then connect the captive nuts of the American inlet and outlet nozzles to the ball valves of the supply and return pipes of the heating system.

- At the blind end of the upper manifold of each heating device, install an automatic or manual valve to bleed air from the system, which is also called Mayevsky's tap.

- For ease of use, instead of the upper faucet, you can install a mechanical thermostat with your own hands, which allows you to automatically maintain the set temperature of the heating radiator.

- Upon completion of installation, test the system at elevated operating pressure, for leakage and leakage of threaded connections.

Tip! To seal all threaded connections, it is recommended to use a special fluoroplastic sealing tape (FUM), which should be wound in a thin layer on the thread, starting from the end of the pipe, along the threads.

Conclusion

Finally, it should be noted that the use of bimetallic radiators is equally effective in both autonomous and centralized heating systems; however, in the case of centralized heating of a residential apartment, only steel pipes can be used to connect bimetallic radiators, because during planned tests, central heating networks can very high pressure for a short time.

More information can be obtained by watching the video at the end of this article, or by studying similar materials in this section on our website.