Device heating in a private house with their own hands: the

Installing heating in a private house with your own hands is not an easy task, which will require specific knowledge and specific skills. It is impossible to transfer the full amount of knowledge required for plumbing and heat engineering calculations as part of the article, so we will give general information, consider the heating device at home and help you choose the equipment.

Heating a private house

Select the type of system

The first step is to understand the types of heating systems and choose the most suitable option.

Heating systems are divided according to various criteria:

- by type of fuel;

- as the heat carrier;

- according to the type of pipe wiring;

- according to the method of circulation of the coolant.

According to the type of heat carrier used, three main types can be distinguished:

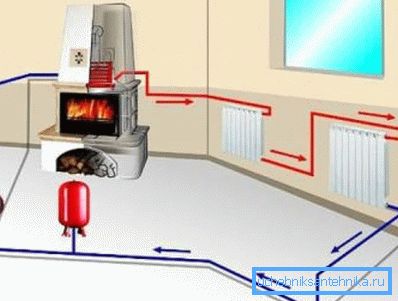

- Water system. This is the most popular and widespread type of heating, where water or antifreeze is used as a coolant, circulating in a closed circuit between the heat exchanger of the boiler and radiators;

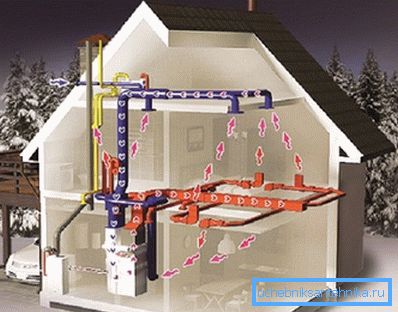

- Air system. Here the coolant is air, there are two ways of organizing work: with the natural movement of air heated from the furnace, and with forced circulation through ventilation ducts with heating from a special installation;

- Electric heating using convectors, underfloor heating or infrared emitters. This scheme does not involve the use of coolant, and the heat is produced directly on the spot.

The water system is quite effective and time-tested. However, it requires the organization of the pipeline, installation of radiators, connecting the boiler and organizing the fuel supply. Instructions for carrying out calculations of hydraulics and heat capacity, losses and thermal insulation are quite complex and require the participation of specialists.

It should be noted that the water type is the most economical, there is a wide range of equipment and consumables developed for this type, as well as a large number of professionals who are ready to make calculations and installation work for reasonable money. High reliability, efficiency and ease of operation make the water heating system the most popular and preferred.

The air system is very comfortable, but its competent organization requires even more serious work: it requires complex and accurate calculation of pneumatics, the organization of air ducts, the installation of fans, heat exchangers, valves and valves, power equipment and other devices. In this case, the air is often heated by electricity, which is economically unprofitable.

Heating systems operating exclusively on electricity are the most expensive to operate due to the high cost of electricity. The price of one kilowatt-hour of heat in an electrical circuit exceeds the cost of the same amount of heat when using gas by almost an order of magnitude.

At the same time, such systems are the most convenient, technological, compact and environmentally friendly. When using electricity there is no smoke, ash, soot, carbon monoxide, tar and other waste, you do not need to clean the chimney and firebox, and the heating works automatically without your participation. Obviously, such a system is suitable for wealthy people, for whom comfort is valued above money.

Note! For the average resident of the private sector, the choice is obvious: the most reliable, efficient, and most importantly cheap in operation today is the water system.

Pipe routing and circulation

The heating device in a country house depends on the chosen radiator layout.

There are three types of pipe wiring:

- Single pipe Here one pipe comes out of the boiler, which is connected to the first battery, then it goes from the second to the next one. The coolant loses energy in each radiator, and the coldest water flows to the last device, which is why the circuit is considered the least efficient;

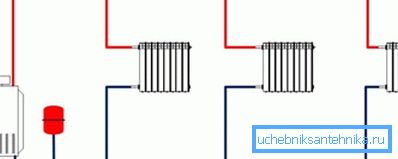

- Two-pipe In this scheme, the wiring has two pipes - supply and return, and radiators are connected to them in parallel. That is, the coolant is fed through one channel, and is discharged through the second one, while warming up occurs more evenly;

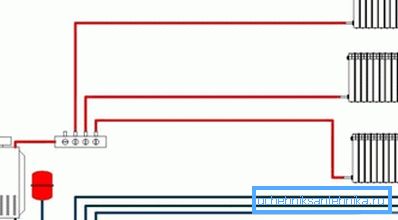

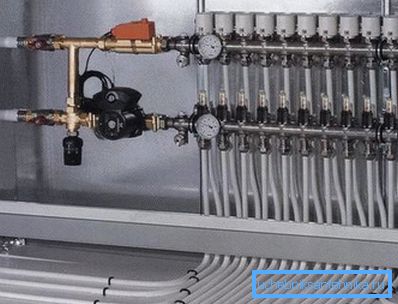

- The collector-beam scheme involves the supply of coolant to the distribution manifold, from where two separate pipes go to each radiator. In the collector unit, it is possible to organize an automated heat distribution system that will allow you to achieve the most comfortable and rational mode of operation.

The one-pipe scheme is the simplest and cheapest due to the smaller number of pipes and installation measures. However, it can effectively heat only a small room with a weakly branched pipeline.

The two-pipe scheme is the most common and popular, as it allows to warm up a significant area evenly and in a timely manner. Here you can also adjust the heat in individual rooms, repair and turn off appliances without stopping the system.

Collector-beam scheme is the most thoughtful and effective, since each device, in fact, has a separate circuit, can be turned off at any time or transferred to a different mode of heat consumption.

The radial layout allows you to organize the most automated and controlled schemes, which as a result gives you maximum comfort and economy, but its installation and design is the most expensive and complicated.

Note! For a small or medium-sized private house, a two-pipe system is sufficient, and for large mansions with many rooms a collector scheme is better suited, it is also used in the construction of underfloor heating.

As a rule, all modern heating systems are built on the forced circulation of water. Such circulation makes it possible to distribute heat more efficiently and economically, and in large branched or collector circuits there is simply no other choice.

Note! The forced movement of the coolant is carried out using a circulating pump, the choice of which depends on the hydraulic resistance of the pipeline and the estimated water consumption of the system. Connects the device through the bypass together with the coarse filter and shut-off valves.

Boiler selection

We are talking about water heating, so we need a boiler. The main criterion for choosing a boiler is the fuel used.

There are several types of units:

- Gas boilers. Distributed most widely due to cheap gas, are the most economical, effective and convenient to use. The equipment is considered relatively inexpensive, but its connection to the gas pipeline requires coordination and the participation of gas transmission network specialists;

- Units on solid fuel. They take second place in terms of thriftiness, however, they lose a lot in terms of ease of use: firewood must be prepared, delivered to the site, placed in a dry room, and then someone should load them into the boiler furnace in time;

- Electrical devices. Convenient and easy to use, adaptable and fully automated. However, the cost of electricity makes them the most expensive and unpopular;

- Diesel units. Combine the high cost of electric boilers with the need for delivery and storage of fuel, it is also necessary to take care of the equipment and heating diesel fuel in the winter;

- As a promising alternative can be considered a hydrogen plant for home heating. Her work is based on the production of hydrogen from water by chemical or electrochemical means, but effective models at an affordable price have not yet been represented on the market.

Note! It should also be remembered that there are multi-fuel boilers that allow the use of two or more types of energy. This increases the reliability and independence of the system.

The choice of the boiler is made simply: if your house is connected to the gas main, then you should choose a gas unit. If the line is not connected - then it remains to choose the type of fuel that is most available in your area and will not ruin you at a cost.

Note! The power is a simplified method of counting: for every 10 m2 of space, approximately 1 kW of boiler power is required, however, it is better to add 20% to this value, and if there are heated floors, 30%. That is, for heating a house of 150 m2 with warm floors will need about 20 kW.

Pipe installation

To install heating in the house, you must be able to mount the pipeline.

The most popular pipes made of polypropylene, so the story will be about them:

- The pipe is cut in accordance with the layout plan using a pipe cutter. The cut must be neat and even, strictly at right angles;

- Then, in the place of the cut, the chamfer is removed. A recess is allowed at a third of the wall thickness with an inclination angle of 45 degrees or a recess of 2 to 3 mm with an angle of 15 degrees. The easiest way is to use a face picker, and a shaver is used for stripping the aluminum layer;

- Next, the pipe is inserted into the soldering iron sleeve, and the fitting is put on the mandrel. The soldering temperature is 260 degrees, we put on the parts all the way with some effort, but do not press on. It is necessary to keep a strictly defined time, which depends on the diameter and is specified in the instructions for the device;

- After heating, parts are removed and quickly connected. The end of the pipe must enter the fitting completely, then it is not necessary to turn or move the parts;

- In this way, individual sections of the pipeline are assembled, which are then mounted onto the wall using special fixings and welded together with each other in weight.

Note! The number of welds on the weight should be minimized, since their quality is highly dependent on your skills and “full hands”.

Conclusion

For self-construction of the heating system will need a lot of knowledge and skills, as well as time and money. With the help of our guide and video in this article you can successfully cope with this task.