Diesel heating boilers - simple but effective

The desire for a comfortable life is often overshadowed by the absence of gas mains or high-voltage lines. When the first place is no longer economy, but the only available opportunity to live like a human being, they often choose boilers for liquid fuel. Imported or domestic diesel heating boilers of Olympia with bithermic heat exchangers will heat a country house in winter and provide warm water in summer.

Diesel boilers - fears and reality

The first thing that comes to mind when the word "diesel"? it is the roar of an engine, belching puffs of black stinky smoke.

In this regard, called the mass of deficiencies, some of which are conditional:

- noise;

- unpleasant smell;

- fuel storage;

- the dependence of the fan and automation on electricity (this problem can be attributed to the national);

- the cost.

Doubtful flaws

Heating boilers for diesel fuel work "clean", but not silently. This is due to the work of the fan, which injects oxygen for complete combustion of the fuel. Thanks to modern technology, noise has been significantly reduced, but not completely eliminated.

In addition, a heating diesel boiler, having impressive dimensions and weight up to 150 kg, needs additional equipment. Therefore, it is better to install floor units in a separate utility room. On the one hand, the boiler room equipment is not cheap, but on the other hand, noise, unpleasant odors, exhaust fumes will not spoil the homely atmosphere.

Special attention will require a chimney for heating. The combustion products contain sulfur dioxide, which forms sulfuric acid with the condensate, destroying the brick. The use of stainless steel materials will help to get rid of the problem, and the installation of such pipes is possible in an already finished room.

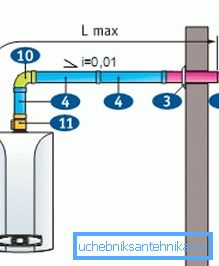

For fuel storage, it is necessary to allocate a free plot of land to dig in a tank with a capacity of 4–5 tons, such amount will be needed for the season. The pipeline leading to the working area must be warmed up, because at -5 ° C the fuel thickens. Such a mass then cannot freely pass through the filters, clogs them and the diesel heating boiler stops working.

Note! If the storage tank is in "natural conditions" you can order winter diesel, which does not lose its properties even with a significant decrease in temperature.

You can store a container of fuel in the boiler room, but in a separate room. Having established radiators of heating, it is easy to maintain the optimum temperature of diesel fuel. Observing the requirements of GOST 305-82, it is important to ensure fire safety with:

- forced and natural ventilation;

- finishing of the room with non-combustible materials;

- have a standard set of fire extinguishing agents.

The obvious advantages of diesel boilers include:

- lack of special permission;

- high power and efficiency up to 94%;

- environmental friendliness;

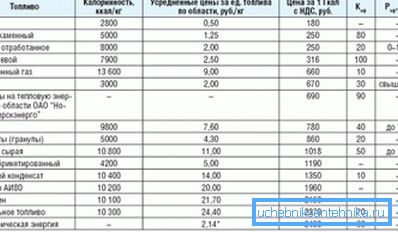

- the price of diesel fuel is approximately two times lower than electricity;

- The efficiency of diesel installations below gas is only 3 units;

- safety - the boiler can be left unattended for a long time.

Based on the foregoing, it is obvious that diesel fuel heating boilers have quite surmountable operation inconveniences. This is even more important if you have no alternative in choosing a heating system. With proper service and proper operation of such a boiler will last several decades.

Possibilities of wall boilers

The reduced copy of the diesel counterpart on the wall is elegant, safe, but has disadvantages / inconveniences that can affect your choice:

- the use of lightweight materials - steel and copper and the rejection of the cast iron heat exchanger, facilitate the weight of the structure, reducing its longevity;

- vibration;

- installation of a coaxial pipe.

In the remainder we have the advantages that allow the use of a wall-mounted diesel heating boiler for the benefit of the whole family:

- compactness;

- low cost;

- protects oxygen;

- automatic control;

- the package includes an expansion tank, a circulation pump and a hot water circuit;

- the issue of noise absorption is solved by separately sealing the boiler body and the burner and installing an additional composite silencer;

- possibility of installation in the apartment.

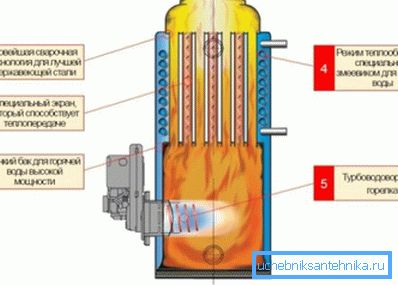

Particularly noteworthy are the Kiturami wall-mounted double-circuit boilers, which use the patented turbo-cyclone burner:

- nitric oxide, carbon monoxide and sulphurous gas are completely burned, increasing the efficiency of combustion and saving fuel;

- it is possible to replace a single broken fragment;

- due to the thrust regulator, ignition occurs smoothly;

- the cost of thermal energy is reduced several times.

The question of saving allows you to give an impressive example. The plant with a heated area of 3200 m2 and a monthly fee for centralized heating of 450,000 rubles. began to pay about 10,234 p., going to the Korean boilers.

Installing 2 units paid off in less than 5 months. Draw your own conclusions.

Heating boiler - what and how

The device of a diesel boiler is quite simple:

- Pressurized burner.

- Fuel filter.

- Pump.

- Remote control panel.

- Temperature sensors.

- Heat carrier.

In the burner, the fuel is mixed with air and sprayed by a fan. Ignition occurs in the combustion chamber, heating its walls and coolant. Special attention deserve the burner - built-in and mounted, which can be changed when switching to another type of fuel.

The heat exchanger is made of steel and cast iron. Each material has its advantages. Steel breaks down faster under the action of an acid that forms below the dew point. Condensate increases fuel consumption, and local overheating leads to breakage.

Heating diesel boilers with cast iron heat exchanger heavier. But their corrosion lasts much longer due to the thickness of the walls. With proper operation, the service life of such a heat exchanger reaches 50 years.

Classification of diesel boilers

The main function of the boiler is to heat the water and, according to this feature, they are divided into:

- single-circuit, performing only heating;

- dual circuit with instantaneous water heater;

- double circuit with boiler for hot water.

By type of traction distinguish:

- natural fired boilers - smoke escapes through a vertical pipe;

- with forced exhaust - smoke removal through a coaxial tube.

Diesel heating boilers differ in the use of 1, 2 and 3-stage burners, whose heat output does not depend on the pressure in the pipe, as is the case with gas analogues.

Note! Attention should also be paid to the depth of suction of the burner, which should be selected depending on the method of storing the fuel tank. If it is buried in the ground, the suction rate should be high, if it is less in suspension or on the floor.

Clean pledge of work

The use of diesel fuel much faster leads to contamination of the internal elements of the boiler. The instruction obliges the owner to inspect the boiler every six months before or after the heating season. At least such examinations should be carried out annually.

Soot even with a thin layer of 2 mm can "eat" up to 10% of excess fuel. At the nozzle and burner splitter carbon is formed, filters get clogged up, and just as time goes on, some parts of the boiler wear out. There may be a threat of fuel leaks or harmful gases.

Serious work is better to entrust the master, not relying on their own knowledge. Only a professional will make serious repairs with the guarantee that you and your boiler can continue to perform their functions in this life.

Note! If you decide to install the boiler and continue to carry out separate repairs with your own hands, you will need to undergo instruction on TB and installation basics.

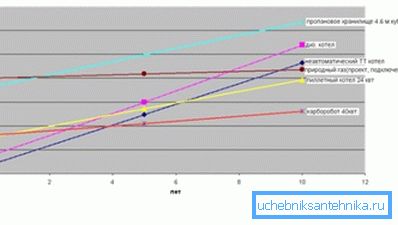

How much fuel is needed for the season

Calculations will be carried out for an area of 100 m2, which will require a boiler with a capacity of 10 kW. According to the formula ratio of 0.1 x burner power, we know the fuel consumption for 1 hour. If 1 kg of diesel fuel equals to a power of 10 kW, then:

0.1 x 10 = 1 kg of fuel for 1 hour of operation.

Consequently, the day will be 24 kg of diesel fuel. If the heating season includes 100 days of work at full capacity and the same number of days of work at half power, then:

(100 x 24) + (100 x 12) = 3600 kg will be the fuel consumption per 100 squares of the room.

Summarizing

Diesel boilers can not be called cheap, but they have one huge and indisputable advantage - independence. Once you fill up the storage with fuel, you can warmly and comfortably live the entire heating season. A small square and reasonable use of diesel fuel will help to extend this period.

The video shows a number of useful tips that will come in handy when using a diesel boiler.