Distribution of heating: how everything works

What is the layout of heating pipes in an apartment building? What is the upper wiring of heating and how does it differ from the bottom? What pipe sizes are used? What is an elevator? Let's try to answer these questions.

Terminology

First, to avoid confusion, we define the terms.

- Elevator, or thermal knot - the place where the management of the heating system and hot water supply of the house or its part is concentrated.

In addition: the elevator unit brings the temperature and pressure of the coolant to the optimum performance for the heating system. Thus, the difference between the supply and return threads of the route reaches 4 kgf / cm2; at the same time, a drop of 0.2 kgf / cm2 is sufficient for the circulation of water through the batteries.

- Water Elevator - the main element of the elevator unit, the mixing chamber, in which the hotter water from the feed is mixed with the return water that is recirculated into the circulation.

- Choke - pipe connecting the flow and return in the elevator assembly. Through it, the colder water of the return pipeline enters a repeated circulation cycle.

- Bottling (plank bed) is a horizontal pipe that supplies coolant from the elevator assembly to the risers.

- Risers - vertical sections of the heating system that supply water directly to the heating devices.

- Liners - pipes connecting the riser to the battery.

So, what kind of wiring diagrams for heating systems can be used in apartment buildings? What elements do they include?

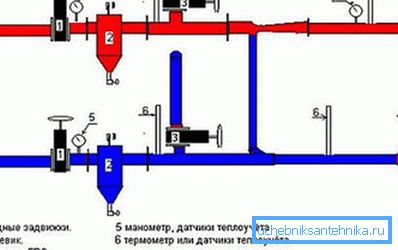

Elevator hub

The minimum gentleman's set for the simplest elevator unit consists of:

- Pairs of inlet valves - on the flow and return.

- Sump on the pitch and, rarely, on the return line.

- Actually elevator with choke and nozzle.

- House valves, cut off the house heating system.

- Pairs of discharges, allowing to completely drain the system.

- Control valves for measuring pressure and temperature.

Optionally can be present:

- Insert hot water (one or two for each line). In the second case, to ensure constant circulation through the DHW circuit, the flange between the inserts on each line is completed with a retaining washer.

- Tie-ins for individual consumers (trade kiosks, shops, etc.). Here she inserts herself on the flange in front of the valves; the washer limits the flow of water through a separate circuit.

Bottling

Depending on their location, there are two schemes for distributing heating.

Lower

Bottom bottling, or heating system with a lower wiring is used in most modern buildings. Both feed and reverse bottling are in the basement. The risers are connected in pairs with jumpers placed in the upper floor apartment or in the attic; At the top of each jumper there is an air vent (Mayevsky's crane).

Each riser is a jumper between the bottling. The inevitable imbalance between the closest to the elevator node and the risers far from it is compensated by the difference in the size and patency of the pipes. We give the typical values of the remote control for the heating circuit serving the entrance to the modern ten-storey building.

| Plot | Do pipe |

| Pouring near the elevator unit | 50 |

| Bottles at the end risers | 40 |

| Risers | 20-25 |

What are the advantages of the lower wiring of heating pipes?

- All valves on the steam risers are concentrated in one place. To disconnect do not need to climb into the attic.

- Resetting the coolant to the technical basement during repairs presents no problems.

By the way: cellars are often used as warehouses or utility rooms of stores. In this case, you know, you don’t have to talk about any advantage: you will have to drop the risers through the hose into the sewer system.

The main disadvantage of the lower wiring of heating systems is the complexity of their launch after a reset. To start the circulation through all the risers, you need to bleed the air. Meanwhile, not all residents of the upper apartments are able to do it; Do not forget about the empty premises.

Upper

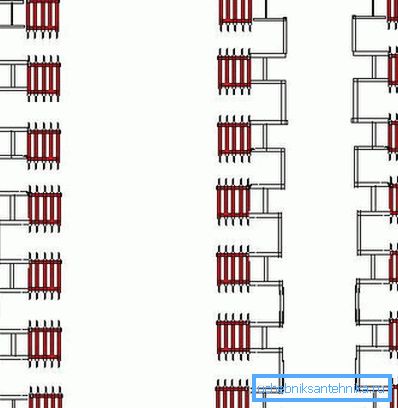

The upper filling or heating with the upper distribution of supply is quite predictably different in that the feeding thread is placed in the attic. The return pipe remains in the basement. Each riser is a separate element independent of other risers.

In the attic, in addition to bottling filing, in this case are:

- Shut-off risers from the valve feed.

- Plugs for their discharge (more precisely, for the suction of air necessary to completely dry the group of heating appliances).

- Expansion tank. Despite the name, it does not compensate for an increase in the volume of coolant during heating (the system is not autonomous, but connected to the heating main). The tank, located at the top of the dispensing dispenser, laid with a minimum slope, serves to collect air, which is removed from there through a waste valve.

Such a layout of the heating system was massively applied until about the 1980s.

How does it look at the background of bottling?

- The main problem here is the complexity of resetting the launch of a separate riser. To completely drain it you need:

- Shut off the valve in the attic.

- Shut off the valve in the basement and unscrew the cap.

- Unscrew the plug in the attic.

It is curious: the whole house heating system with the upper supply wiring is reset and starts much easier, especially if the reset from the expansion tank of heating is brought into the elevator assembly. Alas: the discharge of a house is associated with the loss of a large amount of coolant, which is undesirable from the point of view of saving thermal energy.

- The main advantage of the upper filling is that the launch is extremely simple and does not depend on the residents of the house. It is enough only slowly (in order to avoid a water hammer) to open the house valves on the supply and return lines, after which it remains only to discharge the air from the expansion tank.

Risers

The layout of the coolant in the heating devices in a private house can be horizontal and vertical (standing). In apartment buildings at different sites, these schemes are side by side: if the bottling is always horizontal wiring, then the riser is vertical wiring.

What is useful to know about risers in a block of flats?

- None of the floors, except the upper one in the house with the lower bottling, should not close the pair of struts between radiators. If you embed the heater between the supply and return risers on the fifth floor of a ten-story building, the residents of the upper floors will freeze: the circulation above the tie-in will almost stop.

- In the homes of new projects, one of the twin risers is often made idle (that is, it does not connect to batteries). The layout of the heating system with single risers allows the double risers to be bypassed from the basement, without the participation of residents. It is enough to install a dumper on a single thread instead of a stub and to overtake it for discharge: the airlock will completely fly out on the water front.

- In stalinka on one riser in parallel, two radiators are often connected without changing the diameter. In this case, the riser itself serves as a jumper between their linings. Such

The wiring of the heating system is quite efficient, but only with a large (DU25) diameter of the supply pipes.

Practical consequence: if you want to replace the internal wiring with your own hands, either use pipes for heating of the same diameter, or choke a jumper. The instruction is connected with the fact that with a diameter of 25 mm web and linings with a conditional passage of 15-20, the batteries will simply be cold.

Horizontal internal wiring

In many new buildings, one can come across a relatively exotic scheme: outlets from the risers come into the apartment, which allow the heaters to be diluted for an arbitrary layout. The diameter of the risers and outlets is chosen so that the horizontal contour in your apartment does not set the heating parameters in the apartments above or below.

In addition to an arbitrary layout, a horizontal circuit with one input and output allows you to adjust the accounting of thermal energy. As the cost of heating per square meter increases, the installation of meters becomes more and more relevant.

How to make the layout of heating in the horizontal contour of a single apartment?

In the humble opinion of the author, it would be most reasonable to adapt the Leningrad, or barrack layout, to this situation.

- Along the perimeter of the apartment, an unbroken ring is laid with the size of DN25. Under the doorways, it is heated in a screed or laid under a flat floor.

- Heating devices cut parallel to the ring, without breaking it. The size of the pipes - DNU20. Connection diagram of a separate radiator - lower or diagonal.

- Each radiator is equipped with an air vent in one of the upper plugs. Optionally, throttles or thermal heads and cut-off valves on the supply lines can be installed.

Conclusion

We hope that our recommendations will be useful to the reader. Additional information on how the wiring of heating in the apartment can be implemented will be offered by the attached video. Successes!