Diy heating: the basics of installing autonomous water

What materials do you use plastic heating with your own hands? What heating devices should be used? What is better to use as a coolant?

Let's try to answer these and some other questions.

Heat source

Let's start by choosing the type of boiler.

It is influenced by two factors:

- Unit price of thermal energy. It is clear that the efficiency of heating will always be a priority.

- Ease of use of the boiler. The less often he needs fuel loading or maintenance, the better.

Efficiency

Here the rating of cheapness of heating is as follows:

- Gas. Kilowatt-hour heat, obtained by burning it, will cost only 70 kopecks.

Note: we are talking about natural gas trunk. Gas tank or cylinders will significantly increase costs.

- Firewood will increase the cost per kilowatt-hour of heat to 1.1 rubles.

- Coal will cost even more - 1.3.

- Pellets (pressed sawdust) - 1.4 - 1.8 R / KW * h.

- Solarium - 3.2.

- Electricity when using electric boilers of any type - 3.0 - 4.0, depending on regional electricity tariffs.

By the way: despite advertising assurances from manufacturers and dealers, the efficiency of any direct heating electric appliance is 100%. This directly follows from the laws of physics: a device that does not perform physical work uses all the energy for heating. Economical electric boiler - a myth.

The convenience of use

Here, the types of heating equipment were distributed in a different order.

| Heat source | Comment |

| Electricity | Work offline is possible indefinitely. Removal of combustion products is not required. Possible work on a daily or weekly schedule. |

| Gas | The boiler with electrical ignition and forced autonomy is completely identical to the electric one, but requires removal of combustion products. Non-volatile devices need manual ignition. |

| Solarium | The boiler has the autonomy of electric, but requires the storage of fuel stocks. In addition, the high noise level makes it mounted in a separate room. |

| Pellets | Automated fuel supply from the bunker provides autonomy for several days, after which it is necessary to reload pellets and clean the ash pan. |

| Coal, firewood | Loading the furnace and removing ash are needed every 4 to 8 hours. |

Despite the need for frequent fuel loads, where there is no main gas, heating with solid fuel is mounted with your own hands more often than all other schemes. The reason is precisely its economy.

Increase the autonomy of the system in several ways.

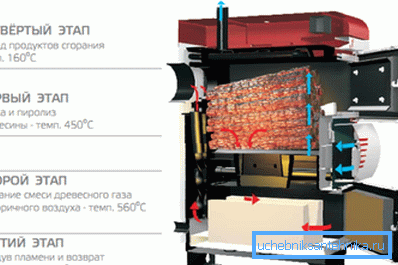

- Solid pyrolysis boiler, unlike the classic, breaks the combustion process into two stages. First, firewood or coal smolders with a limited inflow of air, then products of incomplete combustion — carbon monoxide and volatile hydrocarbons — are burned in a separate chamber. Flexible adjustment of heat output allows increasing the period between kindling up to 10 - 12 hours.

- In the upper burning boiler, the volumetric fire is ignited, as the name implies, from above. Air circulation is organized in such a way that the flow of combustion products carries ash into the chimney. The autonomy of the best boilers of this type reaches a day or more.

- Finally, to reduce the number of daily kindling will help the inclusion in the circuit of the heat accumulator - a massive heat-insulated container with coolant. Working at full power, the boiler heats the water in the tank for three to four hours; then the stored energy is used to maintain the temperature of the heaters.

Pipes

Instead of listing all the materials used in autonomous systems, we allow ourselves to immediately indicate the optimal solution - aluminum reinforced polypropylene.

Why precisely he?

- This material is cheap against all alternatives.

- Pipe hydraulic resistance is minimal and does not increase during operation: a smooth polymer surface is not subject to erosion and does not become overgrown with sediments. For comparison, a new steel pipe may differ from the old one in the flow of water by a factor of 200 or more.

- The resource with typical autonomous system parameters (pressure 1.5 - 2.5 kgf / cm2, temperature 55 - 75 ° C) is estimated to be at least 50 years old.

Why is reinforced polypropylene preferred?

- Combi material is somewhat stronger at break. With the same wall thickness, the maximum allowable pressure for monolithic polypropylene is 20 atmospheres, for reinforced - 25.

Useful: the working pressure of the pipe is indicated in its labeling. It contains the symbols of the form PN * (pressure in kgf / cm2) and PP- * (type of material: R is random copolymer, B is copolymer, H is homopolymer).

- What is more important, aluminum reinforcement dramatically reduces the coefficient of plastic elongation during heating. However, with a large length of straight sections, the elongation will still be noticeable - that is why they are fitted with compensators for heating systems (U-shaped or ring bends of the pipe).

Radiators

Instructions for the selection of radiators for autonomous heating systems for residential low-rise buildings are also quite straightforward. It is better to use aluminum sectional radiators.

The reasons:

- Cheapness Section cost starts from 280 rubles.

- Attractive appearance, able to fit into any room design.

- High heat transfer to the section (up to 210 watts with an inter-axle size of 500 mm) due to the developed finning and high thermal conductivity of aluminum.

All the disadvantages of aluminum - low mechanical strength and the ability to form galvanic vapors with copper - in our case are irrelevant. A hydraulic shock, capable of destroying a radiator, is simply nowhere to take - like foreign metals in a closed loop.

When calculating the heating power of a heater for a room with high-quality external insulation, the easiest way to focus on half-a-century SNiP is 100 watts of heat per square meter.

Additional components

What components for heating systems, in addition to the boiler, pipes and batteries, are used in an autonomous circuit?

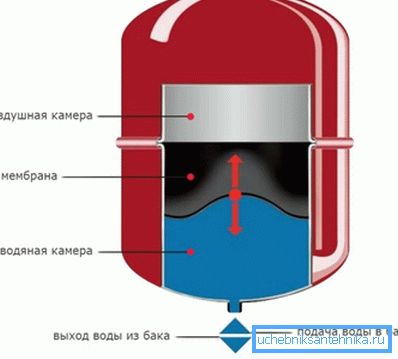

- The expansion tank compensates for an increase in the volume of coolant when heated. Its volume is taken equal to about 10% of the total volume of the contour.

Tip: in a balanced heating system, the volume of water can be roughly estimated at the rate of 13-15 liters per kilowatt of heat output.

- The safety valve relieves excess pressure when the expansion tank overflows.

- The purpose of the automatic air vent is clear from its name: it allows the system to get rid of air plugs in automatic mode.

- A manometer (less commonly, a thermomanometer) serves to visually monitor system parameters.

- A circulation pump circulates the coolant.

Curiously: the above listed basic elements of the boiler strapping are often placed directly in its body. First of all it concerns electric and gas devices.

In addition to the required elements, the design of the heating circuit may include:

- Jumper with a system of cold water supply with a valve blocking it. Through it, the circuit is refilled.

- Vozdushniki (taps Mayevsky or ordinary water taps) in the upper points of the circuit - in radiator plugs or on the jumpers between heating devices.

- Shut-off valve on the flow of each radiator.

- Throttles or thermal heads on the return connection of heating devices, which allow to adjust the heat transfer or to perform balancing of the system.

- Reset, allowing you to completely dry the circuit.

Heat carrier

The most common heat carrier is plain water.

Technical water for the heating system, however, has a couple of serious drawbacks:

- The lime contained in it falls as deposits on the boiler heat exchanger, impairing its heat transfer and reducing the lumen of the tubes.

- When the heating is forced to stop in winter (a typical case is the elimination of a filling or supply line to the valves on it), the water stuck in the radiators turns into ice in a few hours - with corresponding consequences for heating appliances and pipes. Of course, if you do not organize heating the house with alternative means or complete drainage of the circuit with the loss of the entire coolant.

The first problem is completely solved by pouring the distillate. Distilled water in the heating system does not scale in principle. Often, the preparation of water - the removal of calcium compounds from it - is reduced to boiling (salts precipitate) or running through a conventional jug-type filter.

If you want to be safe from defrosting the circuit, the only way is to use antifreeze. In this role, it is better to use an aqueous solution of propylene glycol: it is not chemically aggressive and non-toxic.

How to pour water or other coolant into a closed loop?

The simplest way is to use an inexpensive vibrating pump (Kid or Streamlet) to fill the system. Its outlet nipple is connected with a hose to any gate circuit; the pump itself is immersed in a bucket or tank with coolant. As the tank becomes empty, the coolant is continuously added; pressure in the system is controlled by the gauge.

Useful: before filling the system, it is necessary to pump up the air chamber of the expansion tank with an ordinary bicycle pump. Charging pressure should correspond to the hydrostatic head in the circuit (1 kgf / cm2 per 10 meters of water column). So, if the upper point of the contour is 5 meters above the expansion tank, the charging pressure of the tank will be 0.5 kgf / cm2.

Conclusion

We hope that our recommendations will help the reader in the design and installation of their own heating system. The attached video will offer him more information. Successes!