Domestic gas heating boilers: a review of the best options

Most of the domestic heating systems in the Russian Federation, in the presence of a gas pipeline in a particular region, operate on gas boilers of various types. Moreover, many users do not even suspect that in some situations one can prefer different principles of operation of the aggregates.

In most cases, traditional convection systems are used for the house, regardless of the circuit, that is, it can be radiators or warm pop, and these methods produce space heating at different temperatures. Therefore, let's see together what the difference between convection and condensing boilers, learn about their advantages and disadvantages, how to connect, and also watch the video clip.

Gas boilers for home

Overview of convection models

- PROTHERM PANTERA 25 KTV is a wall bypass convection heating system for which a turbo type chimney is installed. The boiler is powered from a voltage of 220 / 230V with a frequency of 50 Hz and has a power of 147W, current 4A, protection level IP40.

At the same time, its thermal power is 26.5 kW with an efficiency of 92%. As an energy carrier, it is possible to use only natural gas or propane, only the consumption of natural gas is 2.8-1.12 m.3/ hour, and propane - 2,05-0,82m3/hour.

- The temperature range that can be set by a thermostat ranges from 38 ° C to 80 ° C, the optimum working pressure is 0.5–3 bar, the expansion tank has a volume of 7 liters, the stainless steel heat exchanger, and the burner is made of nickel chromium. During operation, there are three possible modes of long-term use, this is winter / summer / vacation, there is an anti-freezing function, protection against jamming of the pump / three-way valve and a pressure sensor for the heating system. Weight 37kg with dimensions (height / width / depth) 7420x410x3110 mm.

- VAILLANT atmoTEC plus VUW 200-5 is a wall-mounted double-circuit convection heating system for which a turbo-type chimney is installed. The boiler is powered from a voltage of 220 / 230V with a frequency of 50 Hz and has a power of 147W, current 4A, protection level IP40. At the same time, its thermal power is 26.5 kW with an efficiency of 92%. As an energy carrier, it is possible to use only natural gas or propane, only the consumption of natural gas is 2.8-1.12 m.3/ hour, and propane - 2,05-0,82m3/hour.

- The temperature range that can be set by a thermostat ranges from 85 ° C to 110 ° C when fed to the line from 75 ° C to 85 ° C, the optimum working pressure is 0.5–3 bar, the expansion tank has a volume of 10 liters, a stainless steel heat exchanger , and a chromonickel burner.

During operation, there are three possible modes of long-term use, this is winter / summer / vacation, there is an anti-freezing function, protection against jamming of the pump / three-way valve and a pressure sensor for the heating system. Weight 31kg with dimensions (height / width / depth) 800x440x3380 mm.

- BOSCH ZWA 24-2 K is a wall bypass convection heating system for which a turbo type chimney is installed. The boiler is powered from a voltage of 220 / 230V with a frequency of 50 Hz and has a power of 240W, a current of 4A, protection level IP40. As an energy carrier, it is possible to use only natural gas or propane.

- The temperature range that can be set by a thermostat ranges from 85 ° C to 110 ° C when fed to the line from 75 ° C to 85 ° C, the optimum working pressure is 0.5–3 bar, the expansion tank has a volume of 8 liters, and a stainless steel heat exchanger , and a chromonickel burner. During operation, there are three possible modes of long-term use, this is winter / summer / vacation, there is an anti-freezing function, protection against jamming of the pump / three-way valve and a pressure sensor for the heating system. Weight 33kg with dimensions (height / width / depth) 7150x400x3550 mm.

Overview of condensation models

- Buderus Logamax plus GB012-24K (Germany), as in the photo above, is a wall-mounted dual-circuit condensing heating system, which is widely used for areas from 100 to 220m2. The boiler operates on a variable network 220-230V with a frequency of 50 Hz and consumes only 120W of power and at the same time it can operate in heating mode 90? C (maximum). The expansion tank of this model has 8 liters, two ribbed heat exchangers are made of aluminum with a nominal capacity of 26.5W.

- With the help of a recuperative heat exchanger, the thermal energy of the flue gases is condensed, and, as a result, the boiler efficiency is 102.5%, and during operation it does not create noise. Fuel consumption is 2.7m3/ hour, exhaust gases are discharged in the turbo mode, there is a circulation pump, display, remote control, electronic ignition and frost protection. The parameters (height / width / depth) are 720x440x355 mm with a weight of 37kg and a warranty period of 24 months.

- Buderus Logano plus GB312-280 with automatic combustion of the boiler SAFe (Germany) is a floor-mounted double-circuit condensation heating system, which is widely used for areas from 140 to 280m2. The boiler operates on a variable network of 220-230V with a frequency of 50 Hz and consumes only 330W of power and at the same time it can operate in heating mode 56-78? C (optimally). The expansion tank of this model has 8 liters, two ribbed heat exchangers are made of aluminum with a nominal capacity of 27.1W.

- With the help of a recuperative heat exchanger, the thermal energy of the flue gases is condensed, and, as a result, the boiler efficiency is 108.0%, and during operation it does not create noise. The inlet gas pressure is 20 mbar, the exhaust gases are discharged in the turbo mode, there is a circulation pump, display, remote control, electronic ignition and freeze protection. The parameters (height / width / depth) are 1517x1410x717 mm with a weight of 330 kg and a warranty period of 24 months.

- Ferroli DIVAproject C24 (Italy) is a wall-mounted dual-circuit condensing heating system, which is widely used for areas from 100 to 220m2. The boiler operates on a variable network 220-230V with a frequency of 50 Hz and consumes only 120W of power and at the same time it can operate in heating mode 90? C (maximum). The expansion tank of this model has 8 liters, the finned heat exchanger is made of copper with a nominal power of 23.5W.

- With the help of a recuperative heat exchanger, the thermal energy of the flue gases is condensed, and, as a result, the boiler efficiency is 91%, and during operation it does not create noise. Fuel consumption is 88 m? / Hour (0.65 kg / h - for liquefied gas G31) exhaust gases are discharged in turbo mode, there is a circulation pump, display, remote control, electronic ignition and freeze protection. Parameters (height / width / depth) are 700x400x330 mm with a mass of 27 kg and a warranty period of 24 months.

Note. Condensation gas domestic heating boilers differ in the principle of operation, which will be described below. But for the consumer the final result is important, therefore, we can say that condensation type models are also called low-temperature models.

That is, their heat exchangers feel excellent at a constant temperature below 60? C, which is extremely undesirable for condensation type. In addition, the convection unit, despite the fact that its purchase price is higher, in the end result is more economical than convection.

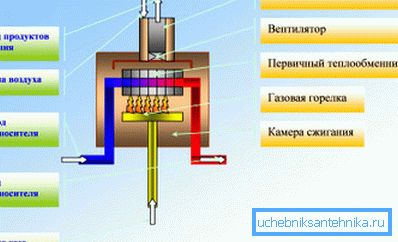

The principle of operation of gas convection boilers

Natural or liquefied gas flows through the pipeline to the gas burner, which is located in the fuel chamber of the boiler, under the heat exchanger. Its location allows flames with maximum efficiency to heat the heat exchanger, in which, in turn, running water is heated (see also the article Gas heating in a wooden house: installation and operation).

The thermal sensor at the output captures the temperature you set, and at the optimum value, the automatic relay cuts off the fuel supply and the burner fades. When the water temperature drops by 1-2? C, the automatic functions again and the electric ignition activates the burner - the heating process enters the active phase and such periodic cycles persist until the boiler is turned off.

When buying a unit, you should know that convection (traditional) domestic gas heating boilers are afraid of condensation, which adversely affects the operating life of the heat exchanger and chimney, since it is not just water vapor, but its mixture with acids generated from propane combustion.

The most dangerous temperature threshold that can be in the heat exchanger? It is between 55? C and 57? C. This suggests that the optimal temperature for traditional units should be 60-80? C, but at the same time the difference in supply and return pipe should be insignificant.

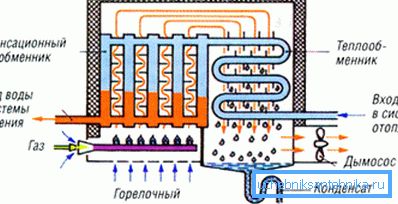

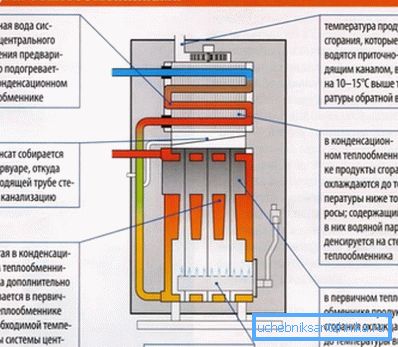

The principle of operation of gas condensing boilers

Condensation heating domestic gas boilers are the most economical - when burning gas, heat energy is transferred to the coolant. But it also produces vapor with acid, which in this case is not displayed on the street, as in a conventional, traditional boiler.

Here, in a special chamber, secondary heat removal occurs, that is, the available products of combustion, which can have temperatures up to 150? C, cool below the dew point (condensation) - 55? C - hence, the name of the boilers. But that heat, which was released in the process of condensation, is wasted on heating the heat carrier.

| The name of the indicator | Value for condensing boiler in% |

| Efficiency maximum | 111 |

| Loss of waste gases | 2 |

| Heat loss | one |

| Condensation loss | one |

| Total efficiency | 107 |

Average efficiency calculation for condensing boilers

Note. A similar calculation, as in the upper table, for traditional boilers will be only 92% efficiency, which is 15% lower, therefore, it can be concluded that savings on condensing units during their operation will be the same 15%.

Such units are most effective at low temperatures (30-50? C), which is the best suited for a floor heating system, and when operating in 60-80? C mode, the efficiency decreases to 94-95% - this is due to a significant reduction condensation of vapors that provide secondary heating of the coolant.

In addition, a two-circuit system for heating and hot water supply for a conventional building with a condensation method of heating the coolant dramatically reduces the emission of carbon monoxide and nitrogen oxides into the atmosphere (up to 70%).

As you understand, the opportunity to save, and at the same time leave behind clean air, immediately caused a sharp demand from mercantile Europeans - in some countries the number of involved condensing boilers reaches 99%. But the British and Belgians have gone even further - in these countries the law generally prohibits the use of convection boilers - only condensing.

But here, not only money saving and limiting harmful emissions into the atmosphere are beneficial - such boilers freely withstand pressure drops from 5 mbar to 10 mbar, and the power loss can be as low as 10%, and this does not affect the service life of the burners at all.

Heat exchangers

Note. Now for the production of heat exchangers, mainly steel, cast iron and copper are used, although aluminum is often used for condensing boilers. From the correct choice of model with a particular heat exchanger depends on the lifetime of the boiler and its cost.

It is more likely that the store will offer you a gas domestic heating boiler with a steel heat exchanger, since such material can be called the cheapest, most durable and easily treatable. The main advantage of steel in such cases is the lowest cost of the unit and the ductility of the material.

But despite this, with periodic heating and cooling, steel is covered with cracks due to the so-called thermal stress. But the disadvantages of steel heat exchangers can be attributed to their susceptibility to corrosion, which is especially dangerous when condensation occurs. As well as a large volume and mass - the larger the volume and mass, the more gas will be spent on its heating.

Cast iron is practically not afraid of corrosion, although the instruction still does not recommend using the unit in such a mode that condensation occurs (55? -57? C). But during the operation of the boiler, such heat exchangers are quite demanding - perhaps the appearance of salt deposits in the burner part (dirty water), which causes cracking.

In addition, due to the temperature difference at the inlet and outlet, low-temperature corrosion may occur, which also threatens with cracking (the four-way mixing valve on the return pipe serves as a salvation).

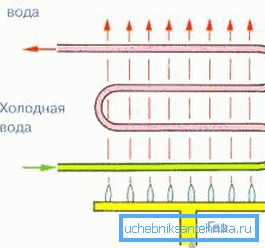

The most effective can be called a heat exchanger made of copper, despite the fact that many consider it unreliable. The ability of copper to quickly transfer the temperature almost completely eliminates low-temperature corrosion and the boilers are able to operate in the mode of 30 ?, and sometimes even lower. Here, the lowest fuel consumption, as copper heat exchangers have the smallest volumes plus good thermal conductivity.

Conclusion

In conclusion, it should be said that you should not install gas boilers with your own hands, even if you understand their device.

For at least two reasons:

- First of all, arbitrary installation and connection to the gas pipe of such a unit is prohibited by law and is fraught with danger (there are many examples of this).

- Secondly, the master with the license will mark the warranty period for you, which automatically implies warranty service, from the date of installation of the unit, and not from the date of its sale.