Domestic water heating stove heat exchanger

The normal operation of any heating system depends on the heat exchanger, a special device in which the heat energy is transferred to the coolant. For heating at home, you can use not only industrial design, but also made yourself. In the latter case, the heat generator is usually a brick oven. Below you will learn the main functions of the device, its effect on the heating in the house, how you can make it yourself and connect it according to the scheme.

Functional features of the heat exchanger

Heating systems for a private house or apartment use surface devices when thermal energy is transferred to the coolant through the metal walls of the equipment.

This principle is most fully implemented in the design of solid fuel, gas or electric heating boilers:

- Circulating water or antifreeze along curved pipes located inside the heater, heated by burning fuel.

- After that, the heated coolant moves through the pipeline of the heating circuit, and the cooled water from the batteries begins to flow into the heat exchanger..

Probably, many of us noticed that with the help of an ordinary brick oven it was not possible to evenly heat the house, in which the rooms did not come into contact with its “rough” one. The solution to the problem can be a heat exchanger installed in it, which will turn it into a water-heating boiler.

Its shape and size should fit into the dimensions of the firebox. It is necessary to connect pipelines and radiators to the device, and then fill the system with coolant - water or antifreeze. After installing the batteries in rooms far from the furnace, it will be possible to make an effective heating in the house.

Kinds

- The most common water and air heat exchangers. The first ones are more practical, as the liquid transfers heat better than air.

- There is also a similar device resembling a storage tank, which is installed outside the chimney.

Tip: industrial heating systems for sale in retail chains are already equipped with heat exchangers. Their design is designed to efficiently heat the coolant.

Often in the factory, such devices are made of copper. The pipe resembles a coil, which has a multitude of plates transversely to the bends, due to which a large area of heat exchange is ensured.

Make at home such an option would be quite problematic. Therefore, it is better to choose a simpler model.

How the system works

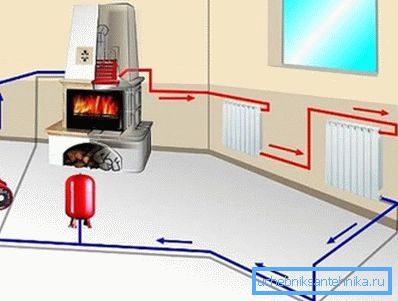

The principle of operation of the heat exchanger, and it does not matter - factory or self-made, the same. The heat generator (boiler or stove) transfers energy from the utilization of the fuel to it, after which the coolant carries it through pipelines to all the rooms.

This method of heating makes it possible to evenly distribute heat throughout the building. It is also important that the premises warm up significantly faster, reducing energy costs.

Stove heating in a private house can be improved in two ways:

- lay a new furnace under a certain size of the heat exchanger;

- put your own device into the existing heating device, made by the size of the fuel chamber.

After that, the owner of the house can be sure that he will receive heating with a water circuit, which will work no worse than the factory solid fuel boiler. The difference will be only in the placement of the inlet of the heat exchanger, which will be located slightly above the floor than the industrial options. This may affect the rate of natural circulation of water.

Tip: connect the heat exchanger to the heating system with the condition that the return pipe is placed as low as possible.

One of the main elements is also the expansion tank, which should be installed at the top of the circuit. With its help, the change in the volume of the heated coolant will be compensated, and the air trapped in the system will be released.

This heating scheme requires to withstand a certain inclination of the pipelines from the top point to the last radiator and from it to the boiler, approximately 10 mm per 1 m.

Tip: if the natural circulation is not enough to heat a large house, install a circulating pump in the heating system. In this case, there is no difference at what distance from the floor the return pipe will be installed.

What is the advantage of heating with a heat exchanger

| Simple manufacturing | When the house already has stove heating, you need to spend money only on creating a home-made heat exchanger and installing a water heating system. |

| The possibility of combined heating | In addition to the surface air heating of the rooms, the coarse furnace will also have a water heating circuit. It can be stretched to remote locations. |

| Use of different types of fuel | Furnaces and solid fuel boilers can work on wood, coal, peat, pellets. If you slightly upgrade the latter, they will also be able to generate heat from gas and liquid fuels. |

| Appearance | You do not have to destroy the Russian stove, if you strive to preserve the national flavor in the interior. The heat exchanger will not be visible from the outside. |

Disadvantages:

- if the device is installed in the furnace of a brick furnace, its efficiency will be lower than the factory boilers;

- In the furnace, it will not be possible to make automatic control over the heating rate of the coolant.

Manufacturing

In this case, the heat exchanger for heating may have a different shape. Most often, it resembles a register made of several copper or steel pipes. Also used and plate heat exchanger of the heating system.

The temperature in the fuel burning zone is very high, especially if anthracite is used. Therefore, there are increased demands on the metal, the design of the device and the quality of the welds.

Material

The device must ensure optimal transfer of heat, therefore the coefficient of thermal conductivity of the metal is very important. For example, a copper pipe holds it 7 times better than steel. In this case, the last 25 m can be easily replaced with the first 3.5 m.

Copper heat exchangers are the most economical in operation, however, and their price is one of the highest. Therefore, most often used steel pipe O32 mm or more.

Tip: when it is assumed most often to burn a stove with coal, we recommend using a cast iron heat exchanger that is able to withstand the maximum temperature of combustion of fuel. Usually use sections of old radiators.

How to calculate power

Calculate this parameter is possible only approximately.

There are many factors to consider, including:

- pipe diameter;

- thermal conductivity of the metal;

- coil length;

- fuel combustion temperature;

- how fast the coolant circulates.

Usually, the real ability of the device to perform its functions is revealed only after the start of the heating system. We recommend to take into account when calculating that 1 m of O50 mm pipe gives approximately 1 kW of heat energy.

Tip: Take for example a well-known boiler model and manufacture a heat exchanger according to its parameters.

Design

The register is a heat exchanger for the water heating circuit of the house, which is welded from smooth-wall pipes. It resembles a kind of "lattice", which is the most popular form for a homemade device.

There are also structures that are simpler in shape - they resemble a rectangular or cylindrical tank. In this case, you should be guided by the fact that the surface area for heat exchange was as large as possible.

We recommend to observe the following conditions during its manufacture:

- the internal width of the voids must be 5 mm or more, otherwise the water may boil;

- use pipes with a wall thickness of 3 mm, then the metal will not burn;

- a gap of 10–15 mm in size must remain between the walls of the furnace chamber and the heat exchanger, compensating for the expansion of the metal when it is heated.

Installation

It is better to install the device simultaneously with the laying of the furnace. Otherwise, you will have to disassemble its part.

The process instruction is as follows:

- Make a foundation for the heat exchanger in the combustion chamber and install it.

- Leave space for feeding and returning the device during further laying.

- Upon completion of the construction of the furnace, connect the heat exchanger to the heating system, fill it with water and make a test furnace firebox.

Conclusion

No matter how good the brick stove is, it will not always be able to evenly heat a house with many rooms. In this case, it is necessary to purchase a boiler or independently make a heat exchanger from steel or copper pipes. So you can increase the efficiency of the heater by several orders of magnitude. Video in the article will provide an opportunity to find additional information on the above topic.