Dual-circuit heating system: design, features, connection

There are two most important conditions for the comfort of housing: the presence of heating and hot water. To ensure these conditions, you can use a separate system, and you can install a double-circuit boiler. We will describe the difference between single-circuit and double-circuit heating systems, what are the features and advantages of double-circuit heating.

Dual circuit heating

The principle of operation and the device boiler

First of all, we want to define the two-loop system, and also to consider the principle of its operation.

Note! Two-circuit is a system in which the functions of heating and hot water are combined by organizing two independent circuits with different water temperatures.

It should be understood that the temperature of the coolant in the heating system reaches 95 degrees, while the temperature of hot water supply according to paragraph 2.4 of SanPiN 2.1.4.2496-09 is 60 degrees. This means that the heat generator will work in different modes.

As a rule, a double-circuit boiler has one closed heat exchanger of heating and one flow heat exchanger of hot water supply.

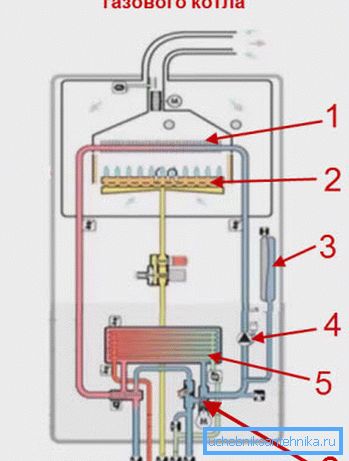

So, consider the principle of the device:

- The coolant enters the heat exchanger (1), where it is heated by the gas burner (2) and sent to the heating system under the action of the circulation pump (4), thus performing a circular motion in a closed heating circuit;

- When the hot water is turned on, the three-way valve (6) is activated, and the coolant starts to circulate through the heat exchanger (5) inside the boiler, while it does not enter the heating system;

- Tap water enters the heat exchanger (5), where it is heated from the coolant and sent to the hot water system;

- The internal small circuit is also closed and provided with an expansion tank (3), which compensates for the expansion of the coolant during heating.

Note! We see that the unit works on the “either-or” principle, that is, when DHW is working, the coolant does not heat the heating system batteries. Prolonged use of hot water can lead to a noticeable cooling of the batteries and a decrease in the temperature in the house.

The option of a bithermic heat exchanger in which two circuits are combined is also possible. Coolant circulates through the outer jacket and hot water from the inner tubes. In this case, the water does not contact the burner flame, and does not boil with the tap closed.

Note! The use of a bithermic heat exchanger allows the use of heating and water supply simultaneously.

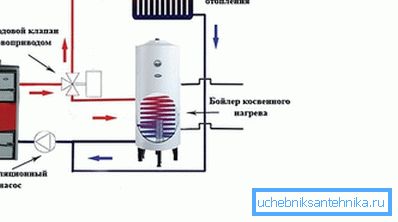

Finally, there are double-circuit boilers with an integrated indirect heating boiler, but they are cumbersome and require the organization of the foundation.

Differences from the single-loop system

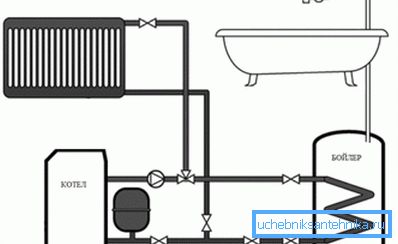

What is the difference between dual-circuit and single-circuit heating system, because single-circuit can also provide water heating? Let's see how the work of a single-circuit boiler with hot water is arranged:

As you can see, here the scheme is different: the boiler heats the coolant that circulates in the heating system. However, a separate circuit is diverted from the general network of the pipeline, which feeds the indirect heating boiler.

When the water in the boiler cools down, the thermostat sends a signal to the servo drive, which switches the three-way valve, and the coolant begins to flow not only into the heating system, but also into the boiler heat exchanger, where the water for hot water is heated. This is reminiscent of the work of a bithermic heat exchanger, only in this case it is not combined, but divided into two separate parts.

Note! Such a scheme is more reliable, however, the price of a boiler with a boiler will be significantly higher than the cost of one double-circuit unit. This is the main difference, in addition, installation of the boiler will require additional space.

Installation of equipment in the boiler room

For proper heating operation, it is necessary to organize a heat point or boiler room.

Despite the automatic control and protection systems installed in modern boilers, the instruction requires the implementation of a number of rules when arranging the boiler room:

- To install the equipment it is necessary to allocate a separate room with an area of at least 4 square meters.. In this room there should be at least one small window and a normal doorway. Most often, the boiler room is arranged in the basement or utility room of the first floor, but you can also take it into a separate building;

- Boiler room decoration should be made of non-combustible materials: tiles, plaster, etc .;

- For the normal operation of the equipment and the safety of the boiler in the boiler room, there must be a normal flow of air. For this, a wall is made unclosed;

- Exhaust gases are emitted through a separate chimney; it is unacceptable to take it to the exhaust ventilation system due to safety measures;

- The floor under the boiler is covered with a steel sheet of at least 1 m2;

- The exit of the chimney raises above the ridge of the roof per meter.

Note! The rules of arrangement of the heat supply station should be strictly followed for your own safety. In case of using gas equipment, it is necessary to familiarize yourself with safety regulations and operating rules.

Advantages and disadvantages

Now consider the pros and cons of using a system with a double circuit.

Let's start with the positive points:

- A noticeable economy of space in the house is achieved: due to the absence of an additional boiler, the boiler room can be made smaller. This is especially true for small houses where space is scarce. In the case of the construction of a special extension for a heat point, savings of funds and materials are added;

- The cost of a double-circuit unit is significantly lower than the cost of a boiler with a boiler or two boilers;

- Connecting a second boiler or an indirect heating boiler complicates installation work significantly, requires additional fittings and a pipeline, automation and control facilities;

- In the case of gas, you do not need to connect two devices with obtaining permits and commissioning, which should be done with the help of specialists.

Note! The main criterion for the selection of such devices is to save space and money. In the people such units were called “boilers for the poor”, but, as you know, poverty is not a vice.

Now let's discuss the negative aspects of this scheme:

- Devices with flow-through water heating are not very convenient in operation: it is rather difficult to regulate the water temperature, especially when the pressure changes. This effect is familiar to the owners of old-fashioned gas stoves;

- The coaxial heat exchanger can work either for heating or for heating. This leads to the fact that with prolonged use of hot water supply the house can noticeably cool down;

- If a combined heat exchanger breaks down, heating will not be able to work until it is replaced;

- Heating running water requires a twofold increase in power, and this leads to an increase in the size and weight of the product;

- Electric boilers in heating mode of running water will also work with double power, and this will require connection to a 380 V three-phase network, which is by no means everywhere.

Note! Obviously, the scheme is rather contradictory, and it’s up to you to decide here. Of course, if buying more convenient and expensive equipment is unaffordable for you, then the choice is predictable.

Ways to increase the thermal inertia of the system

If the winters in your area are cold and you are concerned that when the DHW battery is used to cool down, we will give you some tips on how to avoid it. Of course, first of all, you need to take care of good thermal insulation of the walls and windows, roof and floor, but this is not the point.

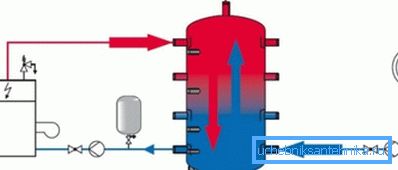

The only way to suspend cooling of the coolant is to increase its heat capacity. This can be achieved by increasing the volume of coolant through the use of pipes of larger diameter.

In addition, you can use massive cast-iron batteries with floor installation. Such heaters cool down for a very long time, since their mass can reach 100 kg.

Finally, as already mentioned, it is possible to integrate a heat accumulator into the system — a tank for several hundred liters (up to 2000) connected between the boiler and the heating system. However, this negates all the advantages of the scheme: it will become more expensive and will take up too much space.

Note! With the rational use of hot water, the problem of cooling the batteries is not very relevant, since in order for the house to get very cold it is necessary to take a shower for several hours.

Connecting gas equipment

Note! Making a gas line connection with your own hands is strictly prohibited. It is fraught with heavy fines and quite dangerous. Therefore, in order to adjust the work of the gas boiler, you will have to perform a certain procedure.

First you need to contact the BTI and make changes to the plan of the house with the introduction of appropriate notes and designation of the boiler room. Also, changes are made in the registration certificate of the object.

Then you need to contact the gas service and submit an application to connect the boiler. You need to provide a technical passport device.

After that, you should install the equipment and install the entire system, except for connecting the gas pipeline. The gas meter must also be installed and sealed.

Now we invite a gas service specialist who connects the boiler to the main line. In parallel, we submit an application to the inspector for commissioning equipment.

Finally, the inspector checks the correctness of the connection, draws up the permits, and if there are no complaints, lets gas into the system.

Conclusion

The two-circuit scheme of the heating system is a good solution for economical owners and owners of small houses. Modern models work quite satisfactorily and reliably.

The video will help you to see this clearly.