Dvukhkolpakovaya heating and cooking stove: and warm, and

If you need to heat a small country house, and also combine the functions of a heating boiler and a stove in one device, then there is no need to look for a better option than a two-bell heating stove. Especially since all the work on its installation can be done by hand. It will help you in this detailed instruction below.

Design features

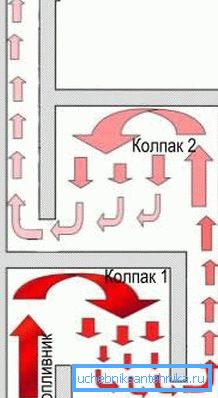

The main difference between the dvuhkolpakovoy furnace from the classic options is that the hot gas generated by the combustion of fuel, moves arbitrarily inside, and not through pre-equipped channels, limited valves.

In this case, the air entering the furnace does not blow heat into the chimney, but rather flows around it from different sides.

The efficiency of the furnace of this design depends on the type of fuel used. In addition, the simplicity of its arrangement allows you to choose and build a structure that best suits your needs.

Let us dwell on the main advantages of the two-bell furnace:

- it can be adapted to any external conditionsI, which allows more economical use of fuel;

- the stove is already equipped with a hob, which allows both heating the room and preparing food (this also achieves significant space savings in the house, since one unit performs several functions at once);

- the design of the furnace already provides for the presence of a hood, therefore, you will not need to install an additional ventilation system for the furnace.

Manufacturing procedure

Required tools

Two-bell heating furnaces are very different from the traditional designs that were used by our ancestors. Without going into details it should be noted that for their design does not need to attract a qualified stove, the price for which services are very high.

All work can be done independently, it is enough to have only initial skills in handling bricks, mortar and trowel.

Before starting work, you should prepare these tools:

- trowel, which is needed for laying bricks;

- a mallet, with the help of which it will be possible to level the laid stones;

- a bricklayer hammer, without which you can not give bricks the right size;

- building level required to align the elements of the furnace horizontally;

- plumb by means of which the correctness of installation vertically is controlled.

Tip! The last two devices can successfully replace the laser level. This is the most accurate tool, however, its acquisition is justified only if large-scale construction is to be carried out.

Materials used

The size of the furnace depends on the area of your country house. As a rule, a small structure is sufficient to ensure an acceptable temperature in a room whose area does not exceed 50 square meters. meters Otherwise, it is advisable to choose a more efficient heating system.

To build a furnace, you need to stock up with enough bricks (about 300 pieces). It must be refractory, otherwise it may crack from exposure to high temperatures.

Also required clay, which is used for laying stoves. In addition, take care of the presence of sand, without which it is impossible to prepare high-quality mortar.

In the hardware store, you should purchase such structural elements in advance (it is impossible or very difficult to manufacture them yourself):

- corners and steel strips - they will be useful for arranging floors at various levels of masonry;

- water-heating and drying box - their sizes depend on the dimensions of the furnace chosen by you;

- latches and doors - are elements of the furnace and protect the room from fire;

- cooking surface - its design can be selected depending on personal preferences.

Masonry furnace

Before describing the design of the furnace, it should be noted that in the construction of a country house, it is necessary to foresee the arrangement of the foundation for it. Otherwise the construction will be unreliable. And casting the base after finishing the floor will be either impossible or too expensive.

The work is performed in the following sequence:

- Laid out the first and second row. They will form the basis, therefore it is not recommended to use broken stones. In extreme cases, they can forget the middle. Moreover, the broken brick at the edges of the masonry will spoil the appearance of the structure.

- An ash chamber is being constructed. It occupies layers of masonry from 3 to 5. In the front of the need to provide a place to install the door. In addition, here you can leave the space used in the future for the installation of the drying chamber.

- The ash chamber is blocked. To this end, the sixth row of masonry is built up inside, after which the grate bars are mounted, which are fixed with bricks of the seventh row.

- The fire chamber is made. It ranks from 8 to 10. The drying chamber is faced with the same bricks.

- Putting overlap. To do this, before installing the 11th row, steel strips are laid on the brick, which are sealed with a mortar coupler from above. When pouring the mixture, you need to provide a place for the arrangement of the chimney.

- Preparing a place for the hob. For this is the 12th row of bricks, which lay the previously hardened clay of the previous row.

- The cooking stove is installed. It is mounted on the 13th row of bricks. A tank can be installed on top that uses the heat of the emerging smoke to heat the water.

- Put the chimney. It starts from the 14th row, and its dimensions depend on the height of the ceiling and other parameters of the room.

Note! Oven dimensions may be larger. In this case, the order of work will not change, you just need to proportionally increase the rows of masonry.

Conclusion

The design discussed above will serve you long and reliably. However, do not forget to properly operate the stove. Before each furnace, it is necessary to clean the combustion chamber from ash and residual firewood, and periodically clean the chimney from the soot accumulated there.

More details about the maintenance of the furnaces can be found in the video below.