Everything you need to know about an electric heating boiler

At cost, electric heating is inferior only to gas, at the same time even small villages are electrified in our country, but things are not so good with gasification, this explains the high popularity of electric boilers for heating. Many manufacturers simplify the task for consumers and equip the boiler unit with additional equipment, including a circulation pump.

Types of electric boilers

Boilers can be classified according to the method of heating water, and the pump for the heating boiler can be installed in the device of any type.

I select such classes of boilers as:

- devices in which water is heated by heating elements. Such electric heating boilers are rather bulky and if the water is hard, then scale will quickly cover the heating element. They are considered the simplest in construction;

- induction - they use the phenomenon of electromagnetic induction. The heating element is a conventional induction coil - on the steel core (which is in the pipe of the dielectric) wound wire, through which the electric current passes. When the boiler is turned on, the current passing through the winding current provokes the occurrence of current in the core, which leads to the heating of the steel rod;

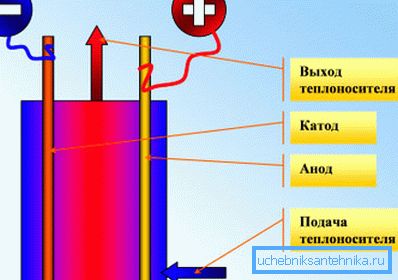

- electrode boilers - can work exclusively with water, as the composition of the coolant is important. Water, in principle, is an ordinary conductor with a rather large resistance. 2 conductors are lowered into it, through which alternating current is then passed, water, like any other conductor, is heated. Devices of this type are not equipped with circulation pumps.

As for the circulation pump and the expansion tank for the heating system, the following options for the location of these elements are possible:

- both the pump and the tank are located in the boiler body - such models are usually preferred if the boiler is located in the house, and not in a separate room;

- the pump can be moved outside the casing; this does not affect the efficiency of its operation.

Electric boiler device and installed additional equipment

Despite the fact that models of electric boilers can be listed more than one dozen, the design in general terms remains unchanged.

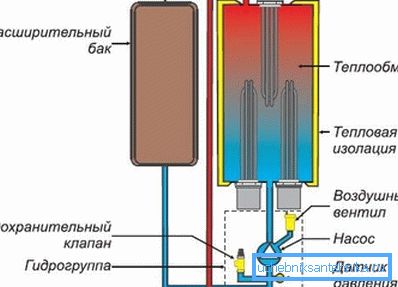

Electric heating boilers with a pump consist of such units (the list is given for a typical heating element model):

- the heat exchanger is a volumetric tank with water, in which the heating elements are immersed, the tank must necessarily have factory insulation;

Note! Adjustment of the heating boiler operation is due to the inclusion of a different number of heating elements. So, to reduce the power of automation just turn off some of them.

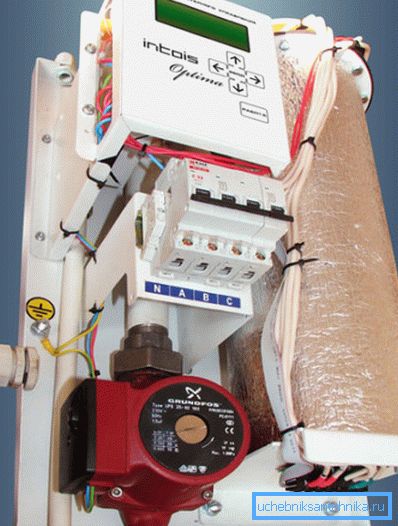

- The hydrogroup includes a circulating pump, a pressure gauge, a valve for bleeding air from the system and a safety valve;

- Expansion tank - needed to compensate for the change in the volume of coolant during heating.

Note! The circulation pump must be located on the pipeline that supplies the cooled coolant back to the boiler. If to put it on the giving pipe, then high temperature will significantly reduce its durability.

More about the selection of the boiler and its installation

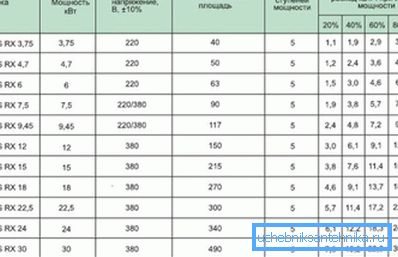

The power of modern electric boilers varies over a wide range. On sale you can find both compact models, the power of which does not exceed 6 kW, and the real "monsters", whose power is approaching 100 kW. It is clear that such devices are used to heat large areas - they are not used in private construction.

Selection of boiler power

In the general case, the selection of the power of any boiler is carried out on the basis of the heat loss of the apartment (or house), the climatic features of the area, the type of insulation, etc. are also taken into account. designs were balanced by the flow of heat from radiators.

With a sufficient degree of accuracy, the required power of the boiler can be determined by approximate dependence. Considering that all modern boilers are equipped with thermostats, a possible slight overcharge is not critical. Yes, and the price does not change much if you insure and take the boiler a little more powerful than received by calculation.

The required power is determined using this dependence in the formula W_k = (S • W_ud) / 10,

such designations are accepted:

- Wto = boiler power, kW;

- S - total heated area, m2;

- Wud - specific power, for warm regions can be taken equal to 1.0, for central - 1.1 - 1.15, for northern - at least $ 1.2

- 10 - conversion factor.

If you use the proposed formula, then for heating a private house with an area of, for example, 160 m2, located in the central part of the Russian Federation will need a boiler with power W_k = (160 • 1.1) / 10 = 17.6? 18 kW.

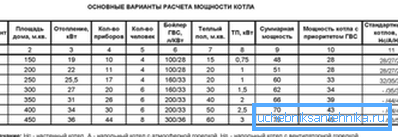

The result was quite close to the values recommended by the manufacturers themselves. So, for an area of 150 m2 recommended 19-kilowatt boiler, the calculation gave almost the same value.

The simplest example is given - it is suitable for calculating the power of a single-circuit boiler. For the selection of a two-circuit device, you need to take into account the energy consumption for heating water for the needs of hot water supply (hot water).

Wiring requirements

A serious obstacle to installing a boiler with your own hands can be that you need to have at least minimal knowledge of electrical engineering. In particular, you need to understand that not every boiler can be connected to a conventional power supply network.

Note! The best option can be considered as laying an individual power supply line for the boiler. If technically it is not possible to do this, then it is better to err and not connect devices with a capacity higher than 6-7 kW to a normal network.

In general, the operating voltage of the electric boiler 220V is found only in relatively low-power devices. If a heating system is designed for a private house, then most likely a boiler with a capacity of about 16-20 kW or more will be used. This means that you have to power it separately.

Note! Boilers with a capacity of more than 6 kW are equipped with a multi-stage power control system. In transitional periods (autumn-winter, winter-spring), this reduces the cost of electricity for heating at times.

Neglecting the selection of the cross section of the wiring will lead to heating of the cable. As a result, the isolation may melt and the possible consequences of such a development cannot be precisely identified as positive.

Instructions for selecting the diameter of the wire is quite simple. You can use the approximate dependence according to which a current of 1 A will require a section of a wire with an area of 1 mm2.

For example, you need to determine the minimum wire sizes for connecting a 6 kW boiler, the connection is made to a normal network of 220 V. Considering this dependence, the calculation will be carried out using the formula S = W_k / (U • I)

in the formula, the following notation is used:

- S = conductor area, mm2;

- U, I - voltage and current, respectively.

In the considered example, the conductor cross-sectional area should be S = 6000 / (8 • 220) = 3.41? Mm? ^ 2.

This approach is considered fairly approximate. Moreover, such a factor as, for example, a conductor material is not taken into account, and this also affects the maximum permissible current load. To select a cable for a more powerful boiler, it is advisable to perform a more accurate calculation.

In this case, the calculation instructions will be a bit more complicated:

- First you need to determine the strength of the current for each phase. The calculation is carried out according to the formula I = W_k / (U_l • v3),

where ul - linear voltage, 380 V in our case;

- in accordance with GOST 16442-80 the section of a vein is selected. In this case, it is necessary to take into account which metal is used - aluminum or copper, as well as the method of cable laying - above or underground.

Consider an example calculation for a 3-phase boiler with a capacity of 22 kW, the connection will be made using a 3-core cable.

The calculation is carried out according to the proposed method:

- determine the current strength I = 22000 / (380 • v3) = 33.43 A.

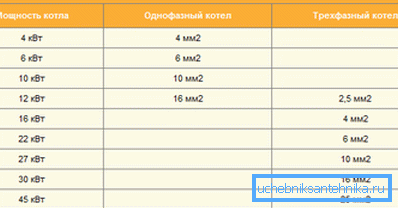

- according to GOST 16442-80, a section of the core is selected, 2 options are possible. If copper is used, it has a 4 mm cross section2 quite suitable, for it the permissible current load will be 37 A, so that also a small margin will remain. For aluminum cores it is necessary to increase the cross-section of the core to 6 mm.2 - the permissible current load in this case will also be 37 A.

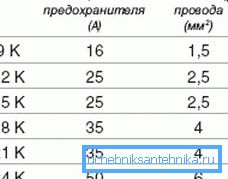

The last thing left to do is pick up a fuse of the appropriate power. You can simply use the appropriate tables, in which for each value of the boiler power the cross-sectional area of the core and the power of the automatic fuse are indicated. For our example, fit the automatic 35A.

Safety requirements

Electric heating boilers with a pump require special attention at the stage of power supply.

Consider the following:

- the power of the automatic fuse should slightly exceed the maximum amperage during operation of the boiler;

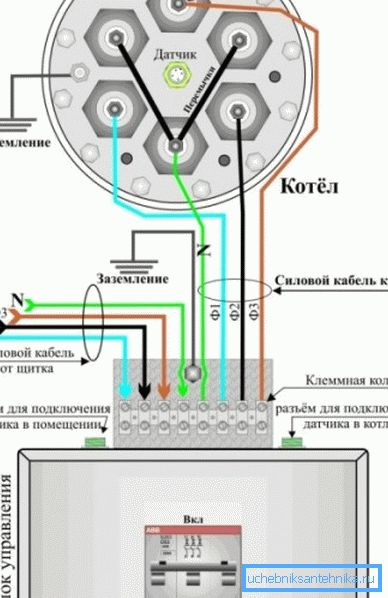

- connection grounding is required. Grounding 3rd or 5th residential cable;

- wire N (zero working) is connected to the shield terminal box (zero bus);

- grounding (PE wire on the diagram) is connected to the appropriate bus (labeled "Earth").

Note! A common mistake when connecting is that people confuse N and PE wires. So at this point you need to pay special attention.

Electric boiler harness

Piping is understood to mean the entire connection process from A to Z, that is, not only the power supply to the boiler, but also the installation of all elements of the heating system (expansion tank, circulation pump, filters, protection group, etc.).

For additional flexibility in regulating heating, you can use a circuit with a mixer. Due to this, the temperature mode can be regulated not only by changing the power of the boiler, but also due to the mixer with a servo drive.

When installing the boiler should follow the following recommendations:

- it is desirable to remove it as far as possible from the water supply system; the electric boiler is placed only in a dry place, this is done in order to avoid a short circuit;

- the compact boiler can be placed on the wall; in this case dowels or anchor bolts are used. Floor models are also popular, for them you can restrict yourself to a simple dielectric stand, of course, the base must be flat;

- then proceed directly to connecting it to the heating system. Naturally, the water supply at the time of installation is stopped. The connection itself is simple, detachable connections are used, so that if necessary it will not be difficult to dismantle the boiler. Pumps for heating boilers are installed closer to the boiler on the return pipe;

- then comes the turn of the electrical part. With the calculation we have understood in the previous sections, the only thing that needs to be noted is that the wires should be placed in the cable channels. Of course, all cables are well insulated, but additional protection will not be superfluous. As the cable channel, you can use a corrugated flexible pipe.

Note! If power surges are not uncommon, then the connection must be made through a stabilizer.

- after that it remains only to fill the system with water and check the tightness.

Summarizing

Electric boilers with pumps is an excellent choice for home heating in areas where there is no centralized gas supply, and there is no desire to use solid fuel analogues. Even at the production stage, the manufacturer supplements the boiler with such elements as an expansion tank and a circulating pump, due to which the installation of the heating system is somewhat simplified.

The video shows an example of connecting a 6 kW electric boiler.