Expansion tank for heating - installation diagram in closed

At installation of some systems of autonomous heating installation of an expansion tank is required. In this article we will look at what this device is, what function it performs and how it is connected to the system.

What is an expansion tank and why is it needed?

From the name of this device, you can guess that it is required for expansion. The fact is that with a change in temperature, the pressure in the system changes as a result of thermal expansion. Since when changing its volume, water or another coolant remains almost incompressible, thermal expansion can lead to the destruction of heating devices.

For this reason, there is such a phenomenon as a water hammer, which can also damage pipes or radiators. The only correct solution in this situation is the inclusion of a tank with air (easily compressible substance) in the system. With such a reservoir, thermal expansion of the coolant will only lead to a slight increase in pressure.

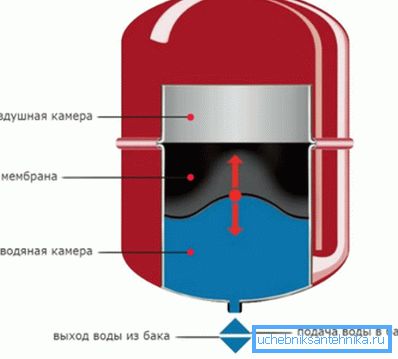

Note! So that oxygen does not dissolve in water and does not cause corrosion inside the pipeline, the water in the tank is separated from the air by an elastic membrane.

It should be noted that the device performs the described function in closed heating systems.

However, expansion tanks are used in other types of heating structures:

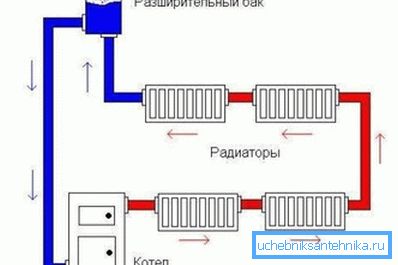

- In open systems that are in contact with air.

- In centralized systems with overflow. In this case, the tank is installed in the attic and is connected to the house heating pipe.

In both cases, the installation of a heating expansion tank is needed to eliminate air plugs from the pipeline. This is due to the fact that the pressure of the coolant in heating systems is not enough to squeeze air from their upper parts. As a result, the expansion tank serves as a tank for collecting air.

In closed heat pipelines, the air is blown off when the heating is started, while in the open, it goes into the atmosphere by itself.

Installation Features

The installation of the expansion tank in the heating system depends on the type of the latter. As mentioned above, heating can be implemented using closed and open methods.

Below we consider how to do a do-it-yourself tank connection connection in both cases.

Open system

Open heating, in essence, is one large vessel with specific convection currents inside.

The installation of an expansion tank for heating in this case, as for all other heating devices, should provide:

- Rapid rise of the coolant heated by the boiler to the upper point of the heating structure, as well as its natural circulation through the heating devices.

- Free and unimpeded upward movement of air bubbles.

For these reasons, the installation of this device is carried out at the top of the structure. Most often, in private houses, these tanks are located in the attic or at the top of the upper stage collector (in a single pipe system).

I must say that the tank itself for an open system is also different in its design:

- Does not require valves;

- Does not need a rubber membrane and even a cover.

In this case, the expansion tank is a simple container into which, if necessary, you can add a bucket of water to replace evaporated water. As a rule, the price of such a device is equal to a pair of electrodes and the cost per square meter of steel sheet is several millimeters thick.

Closed system

If the design is implemented according to a closed scheme, then the installation of the expansion tank of the heating system has a number of features, which we will examine below:

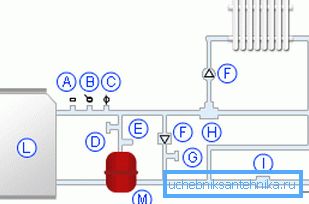

- The most optimal place to connect the device is the area in the place where the coolant flow is closest to the laminar flow and there are no turbulence.. Therefore, the obvious solution is to install it in front of a circulation pump for heating. As for the height of the location, it does not matter, since the task of the device, as already mentioned above, is to compensate for thermal expansion and damping of water hammer.

- Great importance is the location of the tank in space. Ideally, the liquid should flow into the container from above, which will completely remove the air from the compartment with the liquid.

- The volume of the device must be at least one tenth of the volume of all the liquid in the system.. Calculate the volume of water can be based on the power of the boiler - 15 liters of liquid is taken per kilowatt.

Note! Often, heating boilers are equipped with expansion tanks and even circulation pumps. Therefore, before you go shopping for devices, you should make sure that they are needed.

Installation

As an example, consider how the installation of membrane capacity.

So, the instruction looks like this:

- If the connection is made to the existing heating, then first of all it is necessary to turn off all equipment and drain the water from the batteries. To make the liquid flow better, open the taps of Mayevsky.

- If plastic heating batteries are used, the installation should be done through a detachable mounting element, called "American." The first part of it is screwed to the tank, and the second is soldered to the pipe. Then both parts are connected.

- Then you need to cut the heating pipe and install a tee to which the pipe from the tank is connected.

- While there is no water in the batteries, it is necessary to remove the coarse filter and wash it.

- After installing all the elements into place, you need to open the taps and fill the radiators with water. The pressure should rise to 1.2-1.3 kPa.

- At the end of the work should be set off the air and close the taps Mayevsky.

Tip! Before the expansion tank, it is desirable to install a crane. This will allow you to repair the device without discharging water from the batteries.

After performing all the above steps, you can turn on the boiler.

Useful tips

In order for the operation of the device not to cause problems, we recommend that you read the following tips:

- All membrane tanks have a nipple that allows you to pump air up to the required pressure.. From the factory, the devices go on sale with a pressure of 1.5 kgf / cm ?. The same nipple allows, if necessary, to reduce the pressure.

- There are red expansion tanks for heating and blue ones for water supply.. The difference between them lies only in the fact that in blue the membrane is made of food rubber.

- If the safety valve of the tank often works, then its volume is not enough. In this case, you can install in parallel another such device.

- If the liquid in the tank boils, it means that the coolant circulates at a low speed or there is no circulation at all.. Accordingly, the problem lies in the circulation pump.

Here, perhaps, all the main points that you need to know for the successful installation and operation of the expansion tank.

Conclusion

The expansion tank is often a necessary element of the heating system. Moreover, in order for it to effectively cope with the tasks assigned to it, it is necessary to correctly install it, in accordance with the above rules.

From the video in this article, you can pick up some additional information on this topic.