Expansion tank for heating: what is needed, how to choose

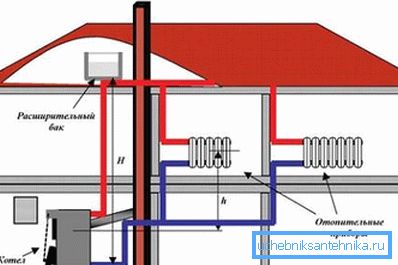

The direct purpose of the expansion tank is to take in excess water, which is formed as a result of heating this heat carrier. The fact is that the water molecules in the hot state expand a little, and if there was no such receiving device, the moisture would find the weakest point of the line and flow at this point.

In addition, the device also performs another function - after the coolant cools, it seems to “give” to the system the missing amount of liquid.

This element, in fact, is an ordinary container that is installed over the entire heating line. But, of course, there are nuances here. We will understand everything consistently and in detail.

The simplest version of the "expander" for heating without forced circulation

Such heating usually consists of three elements - a boiler, radiators or just pipes, as well as a tank. There are no pumps here - the coolant moves along the line in a natural way.

In this case, an expansion tank of an open type heating system is installed in the attic - it is usually made independently. From what exactly can we make the capacity in the table below.

| Initial construction: | Features of use as a tank: |

| 1. Aluminum cans. | These containers, as a rule, are in almost every household. They are very convenient, because they weigh little and have a fairly good volume. As for the shortcomings, we can distinguish such a moment as the impossibility of creating a welded point of connection between the container and the pipe. Everything will have to be done mechanically, and this means that such areas will need constant monitoring for leaks. |

| 2. Products from gas cylinders and sheet steel. | The option is good because you can use welding for the joints - this allows you to achieve maximum tightness of the joints. In addition, steel of this type has excellent resistance to mechanical shock. If we talk about the shortcomings, then this is probably the risk of rust, which will gradually clog the pipes and radiators. |

In general, it turns out that both for handicraft structures - both are good, just need to look at what it is easier for you to get and mount.

Pay attention to two important points! First, the tanks that are put in the attics must be insulated so that the water in them does not freeze. And, secondly, it is very important to prevent the evaporation of water - either a tight lid or ordinary sunflower oil will help here.

In the latter case, a little oil is poured into the container - it forms a layer of "film" on the surface of the water, and this layer prevents moisture from evaporating. Such is the trick.

As for the insulation, it is very simple to perform this operation - it is enough to wrap the can with old jackets, jerseys, etc.

In principle, such home-made designs are quite practical - as time has shown, they have served for decades for years without any particular problems.

We will understand how they are installed.

Installation of “handicraft” cisterns

The scheme of work is usually as follows:

- From any point of the system a vertical pipe rises.

- In the right place overlap drilled hole for the passage of the pipe.

- The highway is “passed” through the overlap.

- In the bottom of the tank is a hole of the same diameter as the pipe.

- The pipe is inserted into the bottom of the can and then the connection is sealed. This is done by welding (if the tank is made of steel) or with ordinary nuts, if a can of aluminum or plastic, for example. In the latter case, at the end of the line you need to cut the pipe thread with a manual die.

As you can see, there is nothing difficult in such work.

Tip: if you make a steel expansion tank of the heating system with your own hands, then try to organize everything so that it contains as few welds, corners, etc. as possible. The fact is that these areas are most at risk of leaks.

Now let's talk about factory products with a completely different principle of action.

Expansion tanks closed

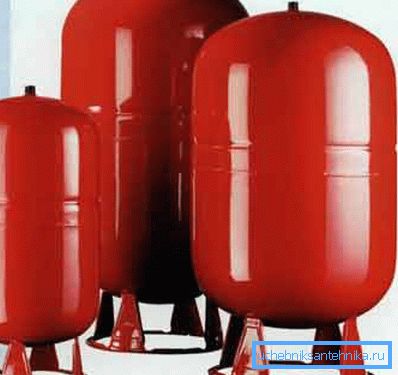

Such containers are designed for indoor installation. They can be put in kitchens, bathrooms, corridors, etc. The most important thing that is important to understand is that these products are operated in systems with additional circulation pumps.

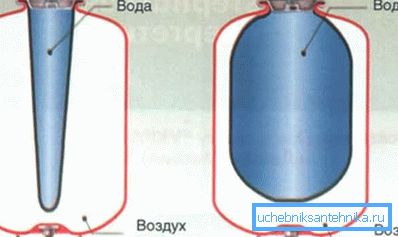

In addition, you need to know something, then inside a closed cistern there is not a solid void, but a special membrane (usually it is made of rubber).

The membrane here is needed for two purposes:

- To create the desired pressure, under the influence of which water will flow back into the system.

- In order to be able to level the force of water hammer.

If more, then “works” is very simple:

- Rubber pear is used to collect excess water.

- Gas or air is pumped between the walls of the membrane and the tank itself. - it turns out that it creates pressure force, which acts on the pear.

- Air is pumped through the nipple using an ordinary bicycle or engine pump..

- The membrane is quite flexible and during the “entry” of water stretches gradually.. This allows you to take hydraulic shocks, rather than directing them to the metal walls.

- The hydraulic loads themselves, drops occur quite often in the systems in which the pumps operate - these are the devices that are the sources, the cause of the blows, since they tend to turn on and change the power of the water flow.

As for the tank itself, the instruction for its manufacture at the factory is such that it usually has in the middle connecting joints around its entire axis. Exactly these seams and are afraid of water hammer.

In principle, the design here is quite thoughtful and safe.

- By finding the water inside the pear, and not inside the metal shell, it turns out that there is no contact of water with air, which protects all steel surfaces of the system as a whole from oxidation. Of course, the process still happens, but at least not as intense as in the case of open-type expansion tanks.

- Tanks are very compact in terms of size - this allows you to mount them in almost any point, without losing valuable space.

- The membrane is so sealed that it becomes impossible to main problem of open-type products - evaporation of moisture.

Please note that in the closed type products there are certain disadvantages. In particular, they relate directly to the membrane. The fact is that rubber has the property of microcracking over time, which leads to loss of air pressure and water ingress into the space of the tank itself, respectively.

Tip: do not buy products of dubious origin and those that are suspiciously low. Use products of famous brands, and then the product will last as long as possible and without problems.

And before considering how to install such a broad tank of the heating system with your own hands, let us touch on another important point.

What volume to put the tank

In fact, there is an approximate rule here - you just need to add 15% to the existing volume of water and make the capacity of the corresponding displacement.

However, this approach is too approximate - it is better to use a special formula that will make your system as efficient, safe and economical as possible.

The formula here is: V = E x C / (1 - Pmin / Pmax) / Kzap

We will analyze it in detail:

- C is the total amount of our coolant in the system.

Please note that not only the volume of pipes and radiators is taken into account, but also the amount of heat carrier that is in the boiler.

- E - here we have substituted the figure of the coefficient of expansion of water under the influence of heat. Or if antifreeze is used in the system instead of water, then we take the parameters of its coefficient. Thus it is necessary to take into account the maximum allowable temperature to which the boiler is able to heat the coolant.

- Pmin is the number of atmospheres of initial pressure in the expansion tank.

- Pmax is accordingly the indicator of the maximum allowable pressure for which the safety valve is set.

- KSAP is a coefficient, a measure of the filling of the expansion tank.

Perform simple mathematical operations, and we obtain the optimal displacement.

Well, now you can go directly to the review of the principle of installation capacity.

Installation of closed devices

It is worth noting that the assembly of such an element is not particularly difficult, because it does not need complex tools, the price of which is high.

In fact, you need a standard "set" of plumbing:

- step and gas key;

- adjustable wrench;

- silicone, tow.

And the very same work order is something like this:

- Fix the tank on the wall plane with brackets or clamps.

Note! Even if your tank is small and does not weigh too much, it is still better to be safe and check the carrying capacity of the wall in the place where you are going to hang it. The fact is that there is possible vibration due to hydraulic shocks and power flow drops. And if the tank vibrates while hanging on drywall, for example, it is likely that sooner or later it will just fall.

- If the capacity is large and it fits more than 30 liters, then it should not be mounted on the wall, but mounted on the floor - on the legs.

- We bring the pipe to the tank and connect everything with the help of nuts or special fittings-adapters.

- We pump air into the container.

- Run water into the system.

In this case, it is necessary to control the level of water pressure - the fact is that if it is excessive, then the membrane will simply rupture.

In principle, this is a fixable matter, but only if you purchased a product with a replaceable rubber “pear”. The pressed membrane cannot be replaced - it will be necessary to take care of changing the entire tank.

If we talk about which membrane is best to buy, then there is no universal recommendation. Pressed "pears" are practically not torn, but if something happens, you will have to change the entire element. And the second option - breaks more often, but then it changes easily and cheaply.

So choose you. This concludes our article.

Conclusion

We have pretty deeply figured out what are expansion tanks, what they are for, which ones are and on what basis they are mounted. I would like to think that such information will be useful to you in practice, and you will be able to plan the most efficient heating system at home. By the way, you can find additional useful information on the topic - in the video posted in the article.