Floor heating: varieties, pros and cons, installation

Underfloor heating is a modern room heating system in which the entire floor screed of your house acts as a heat radiator. This solution allows to achieve the most comfortable conditions for heat supply and heating of residential and public facilities. We consider the main features, advantages and disadvantages, as well as the basics of designing underfloor heating.

System "warm floor"

Species

Underfloor heating systems are often referred to as the common name "warm floor".

There are two types of such systems:

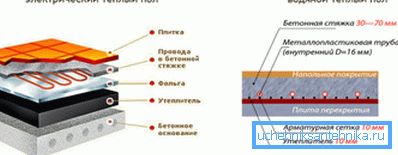

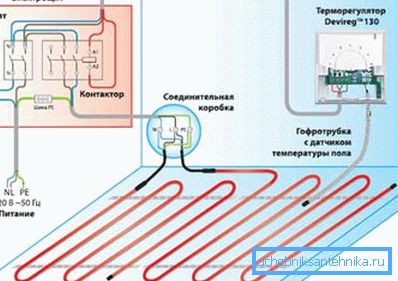

- Electric floor heating using electric heating cable or infrared emitter, laid in the screed or under the decorative coating. A fairly effective solution, but the cost of electricity makes it not very profitable economically;

- Water heating floor with the help of the laid in the coupler contours, which circulates the heat transfer fluid. A more complex, but also more profitable solution that allows you to use this system as the main source of heat.

If we talk about the electric variety, then this approach is obvious: the main source of heat in the house is radiators of hot water, and with the help of a heated floor separate small rooms are heated, for example, a bathroom, a nursery or a hallway. At the same time it is possible to turn on heating only for the period of operation of the room.

In this mode of use, you do not go broke to pay for receipts for electricity, but at the same time get the opportunity to use the advantages of warm floors. Moreover, the system itself and its installation will be cheaper.

Note! If you want to heat the whole house with the help of a floor system or do not want to overpay for the increased consumption of electricity, then you should choose the water option. It is more complex installation and more expensive materials, but as a result, you will save much more.

Device and principle of operation

The design of the system and the principle of its action in the case of water and electric floor has no serious differences. Both in the first and in the second case, thermal energy is communicated to the floor covering, and then radiated by its surface into the room, heating the air and ensuring normal temperature conditions in accordance with accepted standards.

The only difference is in the method of obtaining heat, because in one case, electricity is converted into heat directly in the screed, and in the second it is produced in the furnace of a domestic heating boiler by burning fuel. Further, the energy is transferred to the coolant, which circulates through the pipes and heats the floor.

Adjustment of the electrical system is simple: thermostats measure the air temperature in the room and the floor screed temperature, and based on this data, the control unit decides whether to increase or decrease the heater power. Next, the current is converted depending on the decision.

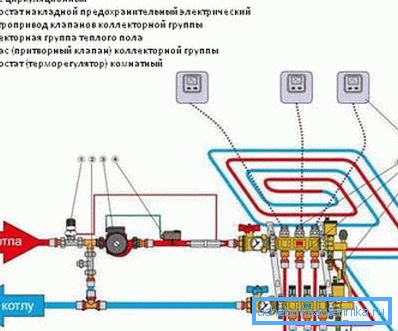

In the water system, the control is more complicated: control automation based on the data obtained gives a signal to the flow valves installed on the coolant supply manifold, and these valves increase or decrease the intensity of hot water supply to the heating circuits. It is also possible to adjust the speed of rotation of the engine of the circulating pump of the heating system.

Note! Water floor heating is a special case of a collector-beam system, the contours of which are laid in the screed instead of feeding the heating radiators. This allows for fine adjustment and the most uniform heating of the premises.

Advantages and disadvantages

Floor heating has many advantages over traditional systems using radiators:

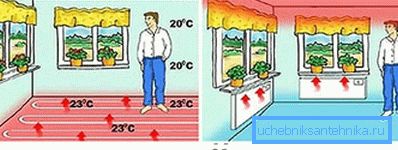

- Since the radiator is the entire surface of the floor, the room is heated as evenly as possible;

- The distribution of heat across the height of the room is considered optimal, since the warmest air is in the area of human activity, while under the ceiling the heating is minimal;

- The high radiation area makes it possible to heat the surface minimally, as a result it is pleasant to walk barefoot on it;

- Low floor temperature eliminates active convection, which reduces the movement of dust and dry air;

- The main amount of heat is transmitted by radiation in the infrared range, which allows you to warm the entire room as quickly as possible;

- The lack of radiators enhances the aesthetics of the premises.

Of course, there are disadvantages:

- The difficult way to design and install makes it difficult to do it yourself;

- The instruction requires the formation of an additional screed, which will raise the floor by at least 100 mm, which will reduce the useful volume of the room;

- The high price of materials and work requires significant investments.

Note! The possibility of fine adjustment and automatic control gives a good saving of energy, especially if we consider a long period of time. This partially offsets large upfront investments.

Installation Features

For those who are coming to work on the installation of underfloor heating, we will give a number of tips.

To begin with, it is better to entrust the design to a competent engineer, because the success of the whole event will depend on the accuracy of the calculations.

It is important to choose the right pipe for underfloor heating. Best of all have proven products made of cross-linked polyethylene, for example, RehauRautitanpink, RehauRautermSili similar. The use of metal-plastic models with the structure of PE-Xc - Al - PE-Xa is possible.

The diameter of the pipe is 16 mm (internal) and 20 mm (external). The pitch is from 80 to 300 mm, depending on the parameters of the room and the calculation of thermal power.

The screed can be made with conventional cement concrete or with a special self-leveling compound for pouring underfloor heating. The second option is preferable, but more expensive. Mounting without screed in the case of wooden floors is also possible.

Foil polystyrene should be used as thermal insulation. You can also combine foam and penofol. Thickness can vary from 30 to 150 mm depending on conditions and intensity of losses.

Note! Connecting the system to centralized heating, especially with a one-pipe wiring scheme, requires the permission of the governing bodies. To obtain such permission is often very difficult.

Conclusion

Floor heating system is a modern and very effective solution that will increase the comfort and coziness of your home.

- The water variant is more difficult to implement, but more profitable from an economic point of view.

- And electric is better to use as an additional source of heat.

For a more complete experience, see our video.