Fuel oil boilers: equipment features, structural elements,

Unlike heating equipment operating on coal or wood, oil-fired boilers use the energy generated by the combustion of diesel fuel to heat the coolant.

This allows you to organize the smooth operation of the climate network without constant attention from the person. This feature has made such systems quite popular in cases where the use of other energy sources is impossible.

Features of the equipment

Externally, the boiler, which works on diesel, differs little from similar climatic equipment operating on wood or coal. Changed only the design of the burner located in the combustion chamber. In order to avoid emergency situations, the climatic equipment is complemented by automatic safety systems, which shut off the supply of diesel fuel in the event of emergency situations.

Moreover, many oil-fired heating boilers - Kiturami, Baderus, Baxi - can be converted for a small amount of time for use with other energy sources. For this purpose, spare parts are used.

The liquid fuel equipment on the market has the following features:

- increased efficiency - more than 90% of the heat generated is to heat the coolant, unproductive losses are minimized;

- wide power range - from the minimum required for heating a small cottage to a very large one, thanks to which it is possible to provide workers with comfort and warmth to an industrial enterprise;

- ergonomic use - the heater can be put into operation with its own hands, after which it is necessary to monitor only the presence of fuel in the tank (periodic loading, as in the case of solid fuel, is, for obvious reasons, not needed here).

Note! Fuel prepared for the boiler must be stored at a certain temperature (not lower than + 5 degrees Celsius). Otherwise, diesel fuel loses fluidity and may clog filters or damage fuel pumps.

Structural elements

Air blower

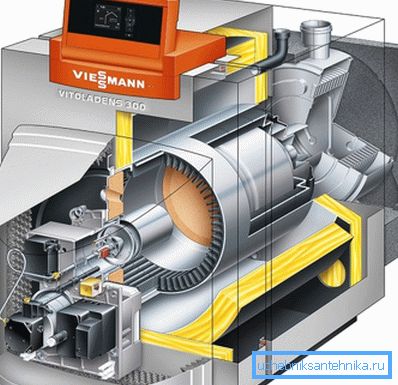

The normal operation of the oil boiler is impossible without air, which is involved in the combustion process. For its supply and mixing with diesel fuel, a special turbine is used. The air-fuel mixture is already subject to ignition.

The process of burning fuel and the formation of heat goes into the combustion chamber. Heat transfer occurs through the walls, behind which the coolant circulates and is transported to the radiators.

To increase the efficiency and efficiency of the equipment, the exhaust gases pass through a complex system of plates and tubes, giving off heat to the water before they get into the chimney.

For the boiler to work in the correct mode, you need to properly configure the operation of the air blower. Only a specialist with relevant experience and skills can help you with this.

Sometimes the heater and burner with air blower are sold separately. Despite the fact that this option is more expensive, it provides an opportunity to purchase the system that best suits your needs.

Note! The greatest damage to the boiler is caused by soot accumulating on the internal surfaces of the combustion chamber and chimney. It is necessary to get rid of it regularly, otherwise it may cause not only equipment breakdowns, but also a fire.

Nozzles for other fuel

Despite the difference in appearance, structurally heaters on different types of fuel are similar to each other. Therefore, manufacturers often supplement the delivery kit with spare parts, which allow preparing the boiler in 20-30 minutes for use with another type of energy source.

The purchase of such equipment, although it will cost you much more, will allow you to make the most autonomous heating system: a gas boiler running on gas can be quickly equipped with a diesel injector in case of interruptions in supply. During this time, the temperature in the rooms will not even have time to go down.

Note! It is especially necessary to reequip boilers connected to gas pipelines. The slightest leakage can lead to very sad consequences.

Uninterruptible Power Systems

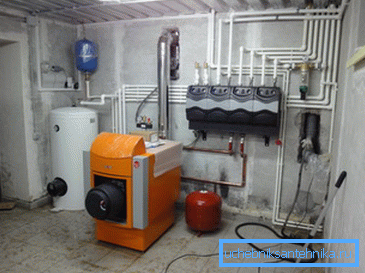

Fuel oil boiler - a complex unit with a large number of electrical and electronic equipment, which requires a connection to the outlet for operation.

In order to avoid stopping the heater as a result of power outages, it is necessary to connect the boiler to the battery uninterruptible power supply of the required capacity or to buy a model already equipped with it.

Fuel tanks

To ensure the smooth operation of the boiler, you need to stock up with a sufficient amount of diesel fuel.

It is important to consider the following features:

- It is advisable to equip enough roomy tank to supply a diesel fuel enough for the entire heating season.

- Capacity must be equipped with heating, otherwise diesel fuel may thicken.

- You must purchase an airtight container that avoids the appearance of an unpleasant odor.

- For an average house with insulated walls about 3 tons of diesel fuel is enough. This calculation is made on the assumption that the heater will not operate at maximum speed all the time.

Advantages and disadvantages of liquid fuel boilers

When choosing a climatic equipment for installation in your own country house, it is necessary to take into account the pros and cons of a liquid fuel heating boiler.

The positive sides of this type of heaters include:

- high efficiency;

- greater power and ease of use;

- the ability to organize automatic feeding of diesel fuel;

- no need for daily maintenance (no need to remove ashes and ash);

- the ability to upgrade the boiler for use with other energy sources;

- the ability to install a burner, which is supplied with waste engine oil (its price is much lower than that of diesel fuel).

Note! The instruction governing the installation of heating equipment does not provide for obtaining permits before installing a liquid fuel boiler (as opposed, for example, to a gas boiler).

But there are also disadvantages, some of which force consumers to make a choice in favor of alternative devices:

- fuel oil heater is quite expensive, as well as various additional equipment;

- the price of diesel fuel used for space heating also leaves much to be desired;

- the boiler requires periodic maintenance, which can only be carried out by a technician;

- the dimensions of the equipment require the arrangement of a fairly spacious and well-ventilated boiler room;

- during operation, the diesel boiler makes a lot of noise.

Conclusion

Fuel oil boilers have many disadvantages:

- they make a lot of noise;

- require a large amount of fuel;

- have not the highest efficiency and so on.

However, if you need to organize a completely non-volatile heating system, then the best equipment cannot be found, because the other methods are either difficult or expensive. For more details on this, see the video posted in this material.