Furnace with a boiler of water heating - features of the

To date, there are many options for heating country houses, in particular, the use of a stove with a boiler is a popular option. This device combines the advantages of the boiler and stove heating. Below we look at the device of the furnace with the boiler, as well as analyze the simple schemes of such heating, which can be implemented independently.

Why use a stove with a boiler

Stove heating is quite economical and very popular in settlements where there is no gas.

However, it has one serious drawback - rooms are heated unevenly, resulting in the following problems:

- Remote rooms may remain cold if they are not additionally heated by electric heaters, which requires additional financial costs..

- Since there is no thermal curtain, which is created by radiators, the windows constantly fog up and even become covered with frost..

To solve this problem, it is not necessary to purchase a heating boiler. You can simply equip the existing furnace with a heat exchanger, from which to carry out the layout to the rooms. All this can be done even with your own hands, without the help of specialists.

Heating system installation

Heat exchanger installation

It is possible to install a heat exchanger in absolutely any oven, for example, it can be a heating - cooking design, just heating or even a fireplace. The main thing is to make a heat exchanger of a suitable size so that it fits in the furnace or is located behind the furnace, which is more preferable.

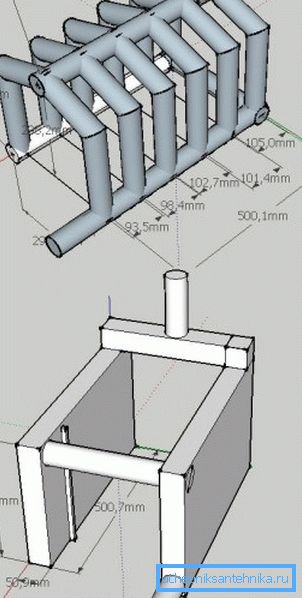

In addition, the heat exchanger must meet the following requirements:

- Between the input and output should be the maximum level difference.

- The surface area of the coil should be as large as possible.

- The design should not interfere with the loading of fuel or impede combustion.

To make the coil better of heat-resistant stainless steel. In this case, the service life of the product will be much higher. The best material for these purposes is thick-walled seamless pipe.

Tip! As a heat exchanger, you can use a conventional cast iron battery. The only thing you need to pre-rinse and clean it.

The heat exchanger can be made independently, if you have experience with the welding machine, or order it from the welder. The main thing is to make the design drawing correctly, indicating all sizes in millimeters.

It should be borne in mind that the boiler power will depend on the size of the coil. In addition, it is necessary to provide a distance of at least 5-6 mm between the walls of the furnace and the coil, designed for thermal expansion of the device.

Tip! If a brick furnace is built from scratch, then it is desirable to give it such a design that the combustion products fall into the chimney with the lowest possible temperature. After all, the more they give the heat inside the furnace, the greater its efficiency. Drafting a project is best left to professionals with experience.

When installing the coil in the finished oven, it will have to be partially disassembled. This should be done carefully, so that later there are no problems during assembly.

Layout

After the solid-fuel stove is equipped with a serpentine, it will become an ordinary boiler. Therefore, all further actions on the arrangement of heating do not have any features. This includes the most common pipe routing, which, depending on the characteristics of the room, can be of two types:

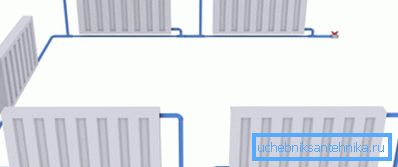

| Single pipe | Heating radiators are connected in series, while one pipe is used for the inflow and outflow of the coolant. The advantage of this scheme is efficiency, however, it is not suitable for homes with a large area, as the last radiators in the chain heat up less than the first. |

| Twin tube | The inflow and outflow of the coolant in such a scheme is carried out through different pipes. Accordingly, all batteries are heated evenly. This layout is the only option in large homes. |

The one-pipe scheme of the heating system is as follows:

- The circuit connected to the stove with a hot-water boiler rises vertically upwards. At the same time, an expansion tank is installed at its upper point. In this way, the upper collector is formed. In the case of forced circulation of the coolant, the upper collector is not installed.

- From the expansion tank circuit goes down and around the perimeter around the room. At the same time to it heating radiators are consistently connected. Moreover, each radiator must have a bypass, which will allow to regulate the heating of the batteries.

Note! To ensure the natural movement of water, it is necessary to provide a constant bias in the system.

Twin tube layouts are a bit more complicated.

As a rule, the scheme is as follows:

- A circulation pump is connected to the boiler.

- Next, the tee is connected to the pump, with which the wiring to the expansion tank and the rest of the system is carried out.

- The supply pipe goes around the whole house and ends at the last radiator. In this case, it connects only the inlets of all radiators.

- A diverting pipe originates from the first in the radiator circuit to which the outlet connections of all batteries are connected.

- The end point of the discharge pipe is the coil inlet.

In such a scheme, a collector may be involved, which will allow to perform several parallel wiring, which may be required in a large house. It should be borne in mind that the price of such a scheme is the highest, so it does not make sense to mount it for small rooms.

Here, in fact, the entire installation instructions for water heating in the presence of a conventional solid-fuel furnace in the house.

Conclusion

A stove with a water boiler can significantly save and simplify the arrangement of hot water heating in the home. The most important thing is to make and install a coil in the furnace. The rest of the work, as already mentioned above, differs little from installing a heating system with a conventional boiler.

From the video in this article, you can get more information on this topic.