Gas boiler for heating and hot water: assistance in the

What are gas boilers that can provide a house or apartment with heating and hot water? By what signs are they classified? How is the heating from the gas boiler? Finally, which manufacturers should pay attention when choosing equipment? Let's search for answers.

Classification

It is possible on several grounds.

Accommodation

Floor boilers are installed, as the name implies, on the floor or on a special platform. As a rule, in the outdoor version, devices of considerable power are produced (from 50 kW to several megawatts).

Their distinctive feature is the absence of strapping elements in the boiler body. The safety unit, pump and expansion tank are purchased and installed separately.

Floor boilers can, in turn, differ in several additional parameters.

- The burner can be tubular (supplying gas to the air through a perforated tube) or blowing (mixing gas and air in optimal proportion).

- Heat exchanger made of cast iron or steel. The heat exchanger of the steel fire-tube boiler is a water jacket around the flame of the burner and provides maximum power, sometimes in megawatts.

Cast iron heat exchanger is more durable, but due to the physical properties of cast iron has limitations on the maximum heating temperature, which limits the power value of a few hundred kilowatts.

In addition: due to the brittleness of the iron, the heat exchangers have to be made extremely massive. Significant weight sometimes causes manufacturers to supply them in separate sections with installation in the boiler during its installation.

Wall-mounted boilers usually have a capacity of up to 100 kilowatts and are equipped with the main elements of the strapping (safety group, pump, and sometimes the expansion tank). In fact, we are dealing with a mini-boiler room.

Wall mounting implies certain limitations on the mass of the product, which determines its design features:

- In wall boilers only tubular burners are used.

- The heat exchanger is made of steel or copper. The second option provides greater compactness, but again limits the maximum temperature of the flame.

Functionality

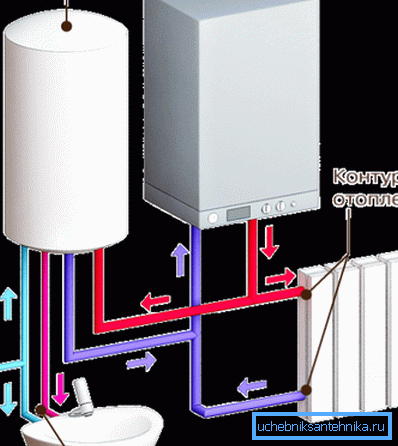

On this basis, boilers are divided into single-circuit and double-circuit. A single-circuit boiler, by definition, is intended only for work on heating and, it would seem, does not meet our requirements: it does not provide for heating the water for hozúr. However, completing the product with an indirect heating boiler, in which the coolant gives off part of the thermal energy, solves this problem completely.

Note! The natural question is, can this structure provide the house with hot water in the summer? Of course. It is enough during installation to provide a separate mini-circuit through which the coolant will circulate between the boiler and the boiler with heating devices cut off by the valves.

The double-circuit boiler has two separate heat exchangers for heating and hot water or, alternatively, a coaxial heat exchanger combined, in which the running water again exchanges heat with the coolant. In addition, there are designs with built-in cumulative heater indirect heating.

Which option to choose a potential buyer?

We strongly recommend to pay attention to designs with storage water heaters. The instruction is related to the more stable hot water outlet temperature they provide: a flow-through heater with automatic power regulation makes an attempt to shower into a continuous struggle with a mixer.

The choice of a product with a separate or built-in boiler is determined solely by the size and configuration of the room allocated for heating equipment.

Traction

It can be natural and forced. Natural draft, characteristic of products with an open (atmospheric) burner, involves the selection of air to maintain combustion directly from the room in which the heating equipment is installed. Combustion products are discharged into the chimney or ventilation duct.

The only plus of the design is complete energy independence.

Several disadvantages:

- The need for a chimney or ventkanal significant diameter (especially when placing multiple boilers on the same riser).

- Heating the channel passing through the room, which obviously will not please the owner in the summer.

- Strict requirements for the room (as a rule - the kitchen), which houses the boiler. In particular, when the boiler power is up to 60 KW, it should have a volume of at least 15 m3 + 0.2 m3 per kilowatt, be equipped with a ventilation window and a supply gap under the door with a cross section of at least 0.025 m2.

In the case of forced traction (the so-called closed, supercharged or turbocharged burner) all the air exchange takes place between the boiler and the street, without the mediation of the room.

Air is drawn by the intake fan through the external channel of the coaxial pipe, drawn through any external wall; combustion products are discharged through the core of the same pipe. The pipe brought out through the wall is equipped with a special grille - a terminator preventing mixing of combustion products and supply air.

Such a scheme, in particular, is used in modern homes with autonomous apartment heating. The only restriction associated with it (except, of course, volatility) is the need to place the boiler on the outer wall of the house.

Ignition

It can be manual (piezoelectric) or electronic. In the first case, a piezoelectric element is used for ignition, the spark from which ignites the pilot burner flame. The main burner ignites from it; The temperature of the heat carrier is controlled by a mechanical thermostat, which stops the flow of gas to the main burner when the desired temperature is reached.

In addition: all piezo-fired boilers are equipped with an additional thermostatic mechanism to shut off the gas supply when the pilot flame is off.

Piezo firing is convenient where there are frequent problems with electricity. The disadvantages can be recorded in the impossibility of remote control of the boiler using remote controls, thermostats and GSM-modules, as well as lower efficiency: the standby burner consumes about 20% of the total gas.

Electronic ignition, in contrast, makes the device volatile; on the other hand, the owner gets the possibility of much more flexible control of the equipment, binding the internal temperature in the house to the weather conditions, drawing up the daily and weekly schedule of temperatures, etc. Volatility is partly compensated by connecting the boiler through the UPS, which can support its operation for several hours.

Heat of combustion

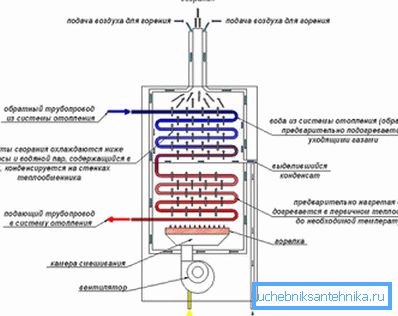

The scheme of operation of a classical (convection) gas boiler using the so-called lower heat value of heat implies a rather high temperature of the heat transfer medium in the return pipe. Its fall below 50 - 55С will cause condensate to fall on the heat exchanger, including not only water, but also quite aggressive acid-containing impurities.

However, if you use an additional corrosion-resistant heat exchanger (economizer) and organize the removal of condensate, you can get two extremely nice bonus.

- The return temperature can be lowered to 30-40 degrees, which will allow to power the low-temperature heating system without too much difficulty.

- The efficiency of the boiler will increase by 9-11%. Condensation of combustion products will give the economizer additional heat.

The sum received on both heat exchangers is called the highest calorific value. It exceeds the amount of energy that even theoretically can be extracted from the process of oxidation of volatile hydrocarbons, which allows manufacturers to say for condensing boilers an incredible efficiency of 105 - 109%.

Installation

How are mounted gas boilers for heating and hot water?

The answer depends primarily on the type of boiler.

- Floor-mounted devices of considerable mass (from 500 kg) require installation on a separate foundation.

- Boilers with an open burner, as already mentioned, require the supply of a sufficient amount of air to the room where they are installed. Do not forget about the restrictions on the minimum volume of the room.

- The coaxial air duct must be removed not less than two meters from the ground and not closer than half a meter from the nearest window or ventilation outlet. The horizontal section of the duct should not be longer than a meter.

Useful: it is better to install the air duct with a slight bias towards the boiler and complete it with a condensate collector. With a bias in the opposite direction in severe frosts, condensate will freeze in the pipe. This does not apply, of course, to regions with mild winters.

- Devices that do not have a pump, the safety group (valve, pressure gauge, air vent) and the expansion tank are equipped with them.

- The pump is usually placed on the return pipe in front of the boiler in order to minimize its heating.

- The surge tank and the safety group, as a rule, are mounted at a distance of 10 diameters of the filling in front of the pump, in an area with minimal turbulence.

- The volume of the expansion tank for the heating system is taken in 10% of the total volume of coolant in the circuit. The amount of coolant in a balanced system is usually calculated at the rate of 13 liters per kilowatt of boiler power.

- The pump capacity is selected in such a way that the entire volume of coolant turns around three times per hour.

- The optimal connection scheme for long sectional radiators is from the bottom to the bottom or diagonal. In both cases, each heating device is equipped with an air vent — a Mayevsky crane, a valve or a water coupling valve.

Important: the connection to the gas pipeline can not be done by hand. This work is done solely and exclusively by a representative of the local gas organization or a licensed service representative of the store that sold you the boiler.

Manufacturers and models

Which manufacturers of gas heating boilers deserve special attention? We will get acquainted with the unspoken brand rating and study a few samples.

Rating

- The highest ranked German manufacturers are Vaillant, Wolf and Buderus. Sometimes Swedish ITSs enter the same category. They are characterized by the highest reliability, the rapid emergence of technological innovations and a developed network of service centers, guaranteeing trouble-free warranty and post-warranty service.

- The second echelon - Italian Ferrol, Ariston and Beretta, Viardus and Dakon come from the Czech Republic, South Korean boilers Kiturami and products of some other European manufacturers. Technologically, they breathe in the back of the head to the Germans and the Swedes.

- Finally, the choice of the most economical buyer - domestic products and gas heating boilers of Ukrainian origin. With rare exceptions, these are non-volatile devices equipped with piezo-ignition. They are fairly reliable, although they do not offer the owner the degree of automation that is characteristic of Western products.

Tip: before making a choice in favor of a manufacturer, read the map of the location of authorized services. It is better to choose a product that, in the event of a malfunction, will be quickly repaired on-site.

Samples

Let's explore some specific models from different manufacturers.

Atem Zhytomyr 3 KS-G-007 SN

| Parameter | Value |

| Type of | Single-circuit convection, with the ability to connect an indirect heating boiler |

| Installation | Floor |

| Burner | Open |

| Heat exchanger material | Steel |

| Power | 7 kW |

| Ignition | Piezoelectric |

| Weight | 37 kg |

| Efficiency | 92% |

| Price | 11070 r. |

Beretta CIAO 24 CSI

| Parameter | Value |

| Type of | Double convection |

| Installation | Wall |

| Burner | Closed with forced ignition and electronic ignition |

| Power | 25.8 kW |

| Efficiency | 84.5-92.8% |

| Electricity consumption | 115 W |

| Coolant temperature | 40 - 80С |

| Maximum consumption of hot water at a water temperature of + 35C | 9.8 l / min |

| Expansion tank | 8 l |

| Circulation pump | 3-speed Grundfos |

| The ability to use the remote control | there is |

| Price | 23650 r. |

Vaillant ecoTEC pro VUW INT 236

| Parameter | Value |

| Type of | Dual circuit condensation |

| Installation | Wall mounted |

| Power | 19.7 kW |

| Burner | Closed with forced ignition and electronic ignition |

| Heat exchanger material | Stainless steel |

| Electricity consumption | 70 W |

| Efficiency | 107% (relative to theoretical maximum calorific value of gas) |

| Heat exchanger for hot water supply | Separate plate |

| Security group | Built |

| Pump | Built-in two-stage |

| Expansion tank | 8 l |

| Weight | 33.4 kg |

| Price | 75330 r. |

Conclusion

We hope that our brief review will help the reader in choosing the heating equipment. The attached video will traditionally offer its attention additional thematic information. Successes!