Gas boilers heating navien: structure and technical

Leaders in the manufacture of boiler equipment is considered to be Europeans. But, unfortunately, recently, acquiring such a miracle of technology, one has to pay more for a popular brand than for the desired quality. Korean-made Navien gas-fired boilers are an excellent and less expensive alternative to offers from Europe.

About them and will be discussed in this article.

Description

When choosing a boiler for your home, first of all you should pay attention to the following points:

- Functionality and performance. That is, the technical capabilities of the device, including its power and additional devices.

- Durability and availability of warranty service. If you invest money in equipment, you want to have guarantees that it will serve you for a long time.

- Appearance and dimensions. The device must fit into the overall interior of the room and have a comfortable size.

Based on this, let's look at the advantages that Navien gas mounted boilers provide to their owners.

The main advantages

- Affordable price. Above, we have already casually noted this feature, but it is worthy to mention it once again: Navien products, not inferior in quality to their Western counterparts, have a much lower cost.

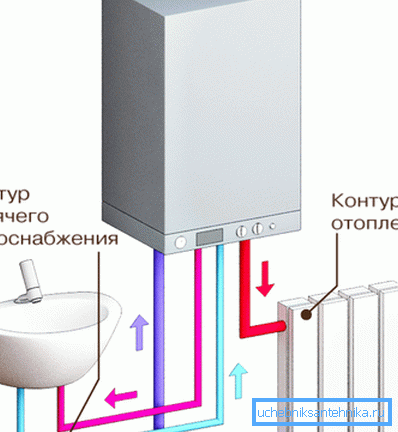

- Two contours. This means that it is possible to simultaneously heat the room and heat water for household needs.

- Stainless steel heat exchanger. Usually, copper is used in such equipment due to its higher thermal conductivity, but this significantly increases the total cost of the entire boiler. Losses in power when using stainless steel are compensated by the turbocharger gas burner.

- Reliable frost protection. In that case, if the temperature of the liquid drops to +10 degrees Celsius, the circulation pump is turned on. With its continued decrease after reaching the mark of +6 degrees, the gas burner starts working, which heats the water to +21 degrees.

- High efficiency. Achieved by the synchronous operation of the turbocharging system and air pressure sensor, which allows you to control the speed of the fan located above the burner. Thanks to this device, gas and air are mixed in the most optimal ratio, which guarantees its complete oxidation. Thus, energy consumption is much more economical.

- Silent work. The walls of the boiler have a high level of sound insulation, which is especially appreciated at night.

- Adaptation to the harsh working conditions inherent in our regions. The described unit is able to withstand voltage fluctuations by 30% of the norm and a drop in water pressure in the system to 0.1 bar, without shutting down. A reduction in on and off cycles leads to an increase in the operational life.

- Ease of operation with their own hands. The boiler is fully automated and equipped with a control panel, simplifying the use of the device.

- Availability of warranty and service. The instruction contains the exact period of time in which your purchased equipment will not be left unattended by specialists.

Tip: It is recommended to make a purchase only in the official representative offices in order to avoid the acquisition of a fake and to have confidence in the legitimacy of the warranty provided.

- Components from one manufacturer. The only part that is ordered from Japan is Time's gas valve. This approach significantly increases the reliability of the assembly, in contrast to those boilers whose components are manufactured in different parts of the world.

Design

Gas heating boilers Navien have the following structure:

| Designation in the figure | Item Name |

| one | Temperature sensor |

| 2 | Coolant flow sensor |

| 3 | Tank for coolant |

| four | Gas-burner |

| five | Additional heat exchanger |

| 6 | Pressure gauge. |

| 7 | Automated air vent |

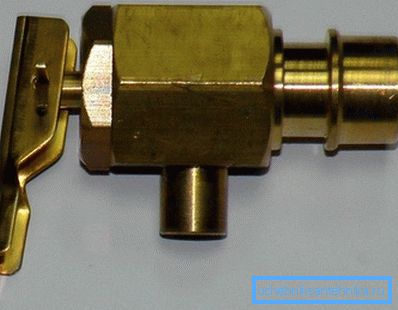

| eight | Three way crane |

| 9 | Circulation pump |

| ten | Supply of heated coolant |

| eleven | Fluid filter |

| 12 | Coolant return flow |

| 13 | Protection valve |

| 14 | Combustion Products Collector |

| 15 | Central heat exchanger |

| sixteen | Electrodes for ignition and ionization |

| 17 | Ignition transformer |

| 18 | Fan |

| nineteen | Control board |

| 20 | Gas valve |

| 21 | Hot water flow sensor |

| 22 | Differential relay |

| 23 | Gas connection point |

| 24 | Cold water supply |

| 25 | Hot water outlet |

Additionally, for the sake of a better understanding of the operation of the device, it is worthwhile to make out the purpose of several of its components:

- Manometer. Designed to measure the fluid pressure inside the boiler. When it falls to 0.5 bar, it is necessary to open the make-up tap and bring it to the normal value of 1.2-2 bar. Then the tap closes.

- Safety valve. It works if the heating water reaches a pressure of 3 bar, opening and dropping excess water.

- Heating water filter. Collects and accumulates various pollutants that are formed in the liquid during operation of the device.

Tip: you must periodically remove the filter and clean it. Otherwise, the equipment becomes overheated as a result of clogging.

You may find abbreviations and special characters on the boiler itself or in its instructions:

- OV - heating water.

- HWS - hot water.

- Cold water - cold water.

- The triangle with an exclamation point inside warns of a danger to life in the event of non-compliance with safety rules.

- A crossed circle indicates a prohibition of action.

- An exclamation point in a circle indicates the mandatory implementation of these actions.

Also in the configuration has a remote control with the following structure:

| Designation in the figure | Item Name |

| one | Screen |

| 2 | Alarm indicator lights up red in the event of a fault |

| 3 | The choice of temperature mode of heating |

| four | Turning on and off of the “Out of home” mode, during the operation of which only the circuit that heats water for household needs works |

| five | The indicator of burning of a gas torch, which lights up green when it is turned on |

| 6 | Temperature and timer control |

| 7 | Setting the desired water temperature |

| eight | On and off |

Features of operation

Warranty service is certainly good, but it ends sometime. In addition, there may be breakdowns that will require long-term repair, during which you will be left without a boiler. Therefore, it is better to follow certain operating rules that will allow your gas device to work for a long time and properly.

Precautions against freezing of the coolant in the system in winter

- Heat insulation pipes. All pipes that are not intended to distribute heat should be enclosed in a warming material, including a water supply pipeline.

- Drain fluid from the heating circuits in case of a long interruption in use. In the opposite case, the remaining moisture can crystallize during the winter period.

- Warming up If the pipes still freeze, heat the accessible parts with a hair dryer. In many cases, such measures can be quite effective.

Case cleaning

The boiler should look aesthetically pleasing, for this it is necessary to monitor its appearance and periodically perform cleaning work:

- Disconnect the device from the power supply.

- Shut off the gas supply.

- An hour later, we clean the surface with a soft, dry cloth.

Filling with water before use

If the contents of the apparatus are not filled with liquid or at least half full, an emergency light will glow red and the boiler will not start working.

Therefore, after its installation, we do this:

- Disconnect the plug from the power outlet and turn off the gas tap.

- Open all shut-off and distribution valves of the heating system.

- Turn to the left make-up valve located at the bottom of the boiler.

- We follow the gauge screen, and when the arrow shows 1.2-2 bar, we close the make-up tap.

After this procedure, you can start the machine. If the emergency light comes on again after the air has been removed by the automatic air vent, and the display shows the error code “02”, then the procedure described should be repeated again.

Drain the boiler

In this case, it is also better to follow a certain sequence:

- Turning off the power and turn off the gas.

- Shut off all hot water shut-off valves and cold water shut-off valve.

- Open the hot water tap at the water intake point, which allows you to drain the liquid from the hot water pipes.

- Open the drain plug, which is located at the bottom of the unit, which allows you to drain the coolant from the heating system.

Cleaning the heating water filter

- Drain the water as described above.

- We are waiting for the boiler to cool, then remove the locking clip and remove the filter itself.

- We wash the filter mesh with water pressure, thereby removing the accumulated dirt.

- We return the item in place, fix the clip.

Conclusion

Gas boiler heating Navien is an excellent alternative to more expensive European counterparts, not inferior to them in quality and durability. Above, we have reviewed the main advantages of this equipment and the features of operation.

On the provided video you can get acquainted with additional information. Navien products will allow you to significantly save the family budget.