Gas convectors heating - alternative heating

In our mighty power, home heating has always been an urgent problem, because in some areas the heating season can last almost 9 months. Gas heating convectors are one solution to this problem. In fact, installing such units in each room, you can forget about the need to install a boiler with complex piping.

But do not flatter yourself, there is a mass of all kinds of pros and cons, which we now talk.

How the system works

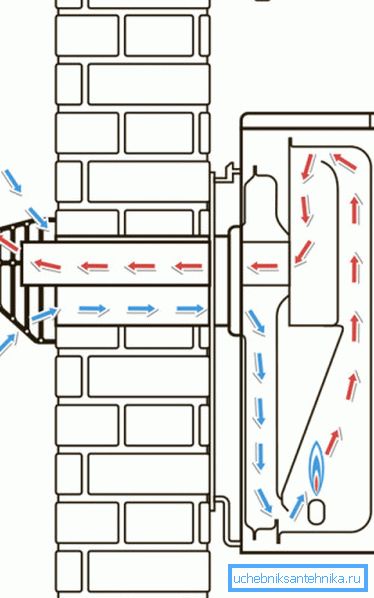

Heating gas convectors are quite simple. If to outline in general, then the usual gas torch is installed in the closed metal casing.

The air necessary for burning the fuel is also supplied there and at the same time combustion products are removed, that is, the chimney is settled. The metal case heats up and transfers heat to the room.

A big plus of modern units is that air from outside is used to maintain work. As a result, the oxygen in the room does not fade, but you will not be able to install such equipment on the inner wall. Because the intake of air and the output of gases is carried out by one combined coaxial pipe.

In the past, such devices were produced with an open gas burner. They had significantly less power and differed little from the usual gas horn of the early 20th century.

Combustion was carried out by oxygen in the room, plus a more complicated chimney construction was required. In fact, it was the same stove, only she worked on gas.

Important: now it is still possible to occasionally meet appliances with an open burner, but they consume more fuel and their operation is unsafe.

Operation and installation

Heating with a gas convector settles quickly enough, but not everywhere it can be installed, plus not every room is advantageously heated in this way.

Advantages and disadvantages

The advantages of such equipment is much greater than the disadvantages. But they all flow from the most important thing, it is economical.

Here, the main role is played not so much by the tricks of the design as by the high energy intensity of the fuel itself.

- This is evident from the elementary calculations, the price of 1 kW of electricity is slightly less than the cost of 1m? natural gas. But the energy intensity of the gas is almost 10 times higher. It is believed that on average to warm 10m? rooms with a ceiling height of 3m, you need to spend 1 kW of electricity. But for heating the same quadrature is enough 0.1m? gas per hour.

Important: these calculations are correct for one unit, which can warm up 1 room. If there are several of them, then the benefits are few and the “scales” are inclined towards the installation of a centralized system with a gas boiler and liquid radiators.

- Undoubtedly, a significant advantage is the universality of the system. Gas heating converters, can be powered by both the gas line and the fuel in cylinders. It is only necessary to change the adapters and can be used. This feature allows operation in country houses or in the countryside.

- Lack of the liquid heat carrier eliminates the problem of water freezing in the system. The convector heats the air, so it can be quickly started and quickly turned off without fear of breakage.

- It was already mentioned above that these units use the air from the street for work, the combustion products are also removed from the room.. Therefore, for the atmosphere of the room they are completely environmentally friendly.

- Technical progress has also touched this equipment.. Thanks to a complex of thermal sensors, power regulators and other automations, gas heating convectors are now conveniently programmable equipment that can safely operate in autonomous mode.

Heating with a gas convector, along with significant advantages, has its drawbacks.

- Any gas equipment requires the execution of relevant documents.

- Compared with the boiler, the size of these units is much smaller, but they exceed the dimensions of most liquid radiators and electric convectors.

- The price of this equipment is almost 2 times higher than that of electrical counterparts, but gas heating convectors pay for themselves in a relatively short time.

Subtleties of choice

Currently, there are both domestic and imported units on the market. Although they have approximately the same structure and principle of operation, there are still differences.

The first thing you should pay attention to is the material of the heat exchanger. The combustion chamber is most often made of cast iron or heat-resistant steel. Cast iron holds warm longer and is considered the most durable, opponents point to its weight, but you don’t have to wear a converter.

Steel heats up faster, but it is less durable. There are also cases of aluminum and copper, but their price is much higher, while the efficiency is not much more.

Units equipped with forced ventilation are much more profitable than devices with natural air flow. Along with the intensive supply of oxygen to the combustion chamber and the rapid removal of gases, the fan increases the circulation of air around the chamber, which increases efficiency.

Having a controlled thermostat in conjunction with automatic ignition can save considerable resources. The temperature sensor can be installed both inside the device and mounted outside. Experts recommend remote controls with a graduation in? C, they are more accurate and reliable.

The complete set of expensive models provided the presence of a remote control. The distance itself does not play a big role, but such units, as a rule, have the function of lengthy programming. This is convenient in summer houses visited on weekends. You can set a gentle mode for the whole week and upon your arrival, program a good warm-up at home.

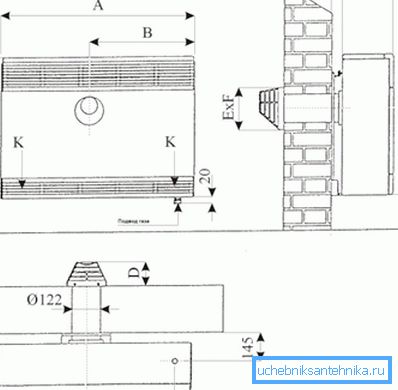

There are 3 types of units, wall, floor and ceiling. Ceiling mounted in the sales rooms and production shops. Wall and floor are used for residential premises, there is not much difference between them, but agree that the device mounted on the wall takes up much less space, plus cleaning the room will be much more convenient.

A few words about the installation

To mount such a device with your own hands is not difficult, the instruction is available to any good owner.

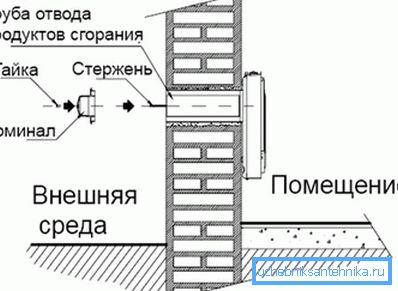

- Choosing a place for installation, it is usually under the window, you should mark the output of the coaxial pipe. Most of these pipes are telescopic and easy to install. The hole is cut by a perforator with a special round crown, while it is necessary to ensure a slight bias towards the street so that there are no problems during rain.

- The dimensions of the pipe outflow on both sides of the wall are made depending on the characteristics of the specific model, the instruction to the collector should contain this data.

- The unit itself is mounted on the wall with four dowels or studs, depending on its weight.

- The gap between the wall and the pipe is filled with mounting foam. The coaxial pipe is a two-circuit design, a chimney passes inside, an air intake is located around it, so the heated parts do not come into contact with the wall.

- Gas supply is performed both by a rigid pipeline and a flexible gas hose. After connection, the tightness is checked with soapy water. The power grid, which provides the fan and automation, is supplied individually.

Tip: you should not connect to the gas pipeline yourself, even if you know how to do it. These works have the right to perform only the relevant organizations with a license, any initiative is threatened with a serious fine.

We also present a video where you can find additional information on this topic.

Conclusion

Summing up, I would like to note that it is advantageous to install gas heating convectors in small premises of a dacha, a garage or as a supplement in a city apartment. For heating of private houses with a large square, a gas boiler and liquid radiators are more suitable.