Gas heating in a wooden house: installation and operation

In this article, we will look at the requirements for gas heating in a wooden house and how it is used. The topic of the article is becoming more and more popular every year, as country houses are built from lumber for all-season living. Buildings in which all-season accommodation is planned need an efficient heating system.

To date, there is a lot of equipment, using which you can heat these or other rooms. But, if the country house is connected to the gas distribution highway, the use of gas heating is the most reasonable and expedient.

However, there is one important point that must be taken into account when designing and constructing such systems: wood is a fire-hazardous material. Therefore, when designing heating in a wooden cottage, you need to take care of fire safety.

Variants of the heating system

Gas heating of a wooden house with your own hands can be performed in accordance with two schemes:

- First option - the use of traditional two-or single-circuit boilers. The advantage of using such units is the autonomy of their operation. For example, many models of foreign production are used according to the “set and forget” principle.

Such a device, being equipped with a thermostat, independently maintains the specified temperature parameters. In addition, if you are away for a long time, the boiler will automatically run water through the system once a day so that it does not stagnate.

A significant advantage of Western European boilers is their efficiency. The fact is that this equipment was originally designed for countries where the cost of natural gas is high. Therefore, such installations are much more economical and more powerful than domestic developments.

The boilers are ergonomic, no matter what you purchased - floor or wall model. Finally, such installations are fire safe.

Among the shortcomings should be noted the need to draw up and coordinate the project of the heating system. In addition, the price of truly high-quality imported equipment is high.

- Second option - the use of gas convectors. Such a solution is the best option if there is no prospect of connecting to the main line, and gas is sold only in cylinders.

The disadvantage of convectors is the possibility of heating a limited space. Therefore, if the building object is multi-room, you will have to invest money in the purchase of several devices, respectively, the price of the heating system will be high.

Another disadvantage of converters is their limited functionality. For example, if the boiler heats the room and heats water for consumer needs, then the convector only heats.

Chimney device in a wooden structure

The exhaust gas discharge instruction is largely determined by the type of heating equipment:

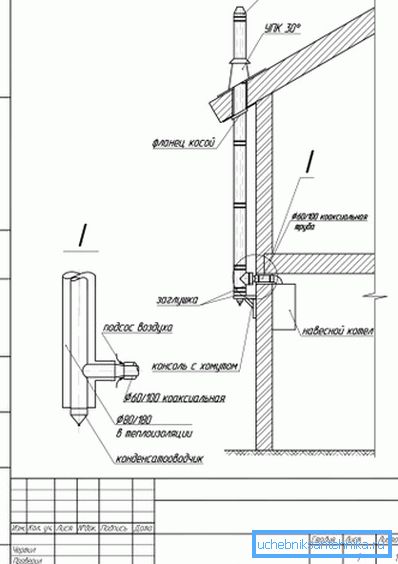

- By purchasing a modern gas boiler with a closed-type combustion chamber, you can count on the installation to be equipped with a forced draft. This hood is a neat compact pipe no more than 100 mm in diameter.

An axial fan is built into the nozzle, consuming no more than 100 watts. Installing the exhaust pipe in the hole made in the wall, the gap at the edges of the chimney is filled with foam.

- Installation instructions for open-type combustion chambers are different. In this case, it is necessary to build a full-fledged chimney, which will pass through the roof.

The main requirements for such chimneys, is the lack of direct contact with wooden structures. In addition, the exhaust device should not have more than three bends.

Of course, during the construction of the chimney and its connection to the heating equipment, it is necessary to ensure absolute tightness in order to eliminate the possibility of penetration of carbon monoxide into the room.

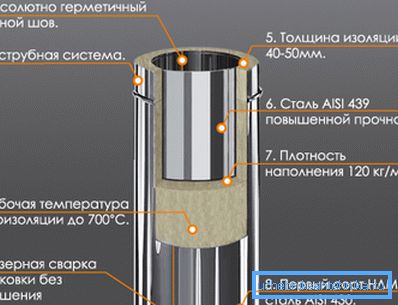

Important: In order to comply with the fire safety regulations, it is advisable to purchase a ready-made insulated chimney.

Systems made according to the “sandwich” scheme have a thermal insulation layer located between two metal shells. Therefore, during installation, such structures can be leaned directly against the elements of the truss system or to other wooden structures.

Location of heating equipment

The instruction of the location of heating equipment is largely determined by its design and operational features.

Consider where and how to fix heating units operating on gas:

- Convectors in terms of air exchange efficiency, it is desirable to place directly under the window opening. The front edge of the device should protrude slightly beyond the sill line.

Of course, for safety reasons, it is not recommended to use fabric curtains on the window opening. You can limit the installation of plastic or metal blinds directly in the window opening.

- Heating boilers mounted type with a closed combustion chamber and forced exhaust can be installed almost anywhere where it is convenient to bring all the necessary communications. For installation of floor-standing boilers it is advisable to allocate a special room.

Important: Both types of heating equipment are installed and operated in accordance with a specially designed and approved project.

- Heating boilers with an open combustion chamber are mounted exclusively in specially designated rooms with a specially equipped exhaust gas exhaust system and with ventilation arranged in accordance with the project documentation. As well as the previous categories of heating equipment, boilers with an open combustion chamber require a specially developed and approved project.

Conclusion

Now that we have considered the main types of heating equipment operating on natural or liquefied gas, you can choose the device that will fit the characteristics of your country house.

Do you have questions that require comprehensive answers? More useful information can be found in the video attached to this article.