Heat carrier for heating systems: purpose, properties,

The heat carrier for the heating system is a means of energy transfer from the place of its generation to the heater. We are talking about water heating systems, so we will consider only liquids. In the article you will read about the features of the use of different types of coolants for heating.

Heat carrier in heating systems of buildings

Purpose

Coolant for heating is an essential element, without which the operation of the system is impossible in principle.

Previously, a person used a direct method of heating due to an open flame: in the dwelling there was a hearth in which firewood was burned. Over time, civilization abolished such a method as dangerous and uncomfortable, and the hearth moved to the boiler furnace, and the boiler itself was located in a separate room at home or outside.

However, such a redeployment required the invention of a method of heat transfer over a distance, and here we see the emergence of such a thing as a coolant: a substance capable of storing thermal energy for transportation from the boiler house to the end user. The first coolant used by man was air.

Over time, the space heating systems were improved, and eventually the water contours of heat transfer appeared. Since then, water is the main type of agent for transporting thermal energy for heating residential and public facilities.

Today, the range of agents used has expanded, but for household systems, the most common water remains. In local and autonomous networks often use mixtures consisting of water, antifreeze, and a complex of additives that reduce the corrosivity of the medium.

Note! The heat carrier is the most important element of heating, on the properties of which depends many of the determining parameters. Therefore, the choice of heat carrier should be taken seriously and as responsibly as possible.

Basic parameters and requirements

In order to better understand the requirements that a heat carrier must meet, consider its full working cycle:

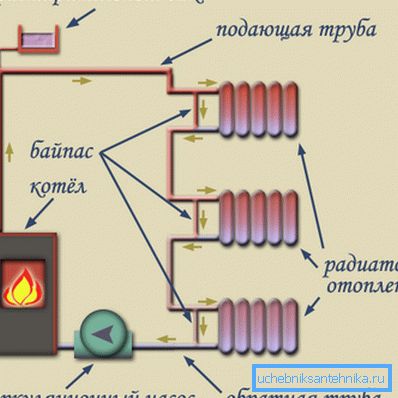

- Heat carrier for heating is poured into the system, consisting of a heat exchanger of the boiler, feed pipe, radiators, expansion tank and return pipe;

- Burning fuel or heating element heats the water in the heat exchanger, and it starts a natural or forced circulation around the contour;

- Since the system is closed, a new portion of the substance immediately enters the place of the liquid that has left the heat exchanger., which also heats up and enters the pipeline;

- Water piped into radiators, where the heat agent gives its energy to the environment due to heat transfer, radiation and convection;

- Through the return line, the cooled liquid returns to the heat exchanger and the process repeats.;

- To compensate for thermal expansions, an expansion tank is used for heating systems. open or closed type.

Obviously, to characterize the energy transporter, such an indicator as the ability to accumulate heat is important. If we draw an analogy with the motor transport, it will be the carrying capacity of the machine, and in our case this parameter is called the heat capacity.

We will not go into the analysis of various liquids, but note that water is distinguished by the highest heat capacity of all liquids (not counting melts).

However, the parameters of the heat carrier of the heating system are not limited by the heat capacity, although this is a very important indicator. Such characteristics as the temperature of phase transitions from one aggregative state to another, that is, the boiling point and freezing point, also have a strong effect on heating.

Note! Water is practically ideal for heating residential and public buildings, provided there is constant heating during the cold season. However, for autonomous systems operating in a short-periodic mode, freezing of water is fraught with rupture of pipes and system failure.

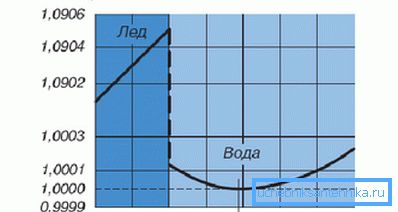

In addition, it should be remembered that liquids exhibit this behavior under conditions of temperature drop:

- with increasing temperature, they expand;

- and when they fall, they narrow;

- but when falling below the transition point to the crystalline phase, the volume begins to grow again, and the water here shows an abnormally high expansion - up to 9%.

This makes it impossible and dangerous for pipes to use water in conditions of possible freezing, the only salvation is to drain the coolant, which is fraught with increased corrosion of the walls.

The maximum temperature is limited by the norms of fire and traumatic safety, so it makes no sense to heat the coolant above 95 - 110 degrees. In this regard, water suits us, but in order to avoid boiling up, this indicator is sometimes increased by adding various impurities.

Another important parameter is the viscosity and surface tension of the fluid. Since our system is a closed loop with interconnected pressure vessels, we must take into account hydraulic laws and processes. To ensure the normal circulation of the agent at a given speed, it is necessary to overcome the hydraulic resistance of the pipeline, which is directly proportional to the viscosity.

Note! The lower the viscosity, the easier it is for the pump to move the coolant around the contour. This directly affects the efficiency of the system and the energy costs of the pump.

As a rule, viscosity is limited by such a parameter as the velocity of the coolant in the heating system. It should not be lower than 0.2 - 0.3 m / s.

The overwhelming majority of pipes are made of rolled steel, therefore it is important to take into account such a liquid indicator as corrosivity and rigidity.

Water itself is not a hazardous medium, however, in the presence of oxygen and various impurities, it can cause appreciable damage to the material of the vessel walls. This problem is solved by a set of measures, which is called water treatment.

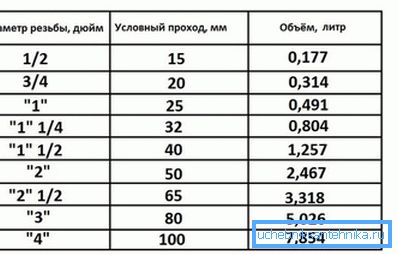

The amount of coolant in the heating system is determined by calculations. A simplified calculation of the coolant in the heating system looks like this: the volume of the boiler + the volume of heating devices + the volume of water in the pipes + the amount of liquid in the expansion tank.

The first two parameters are determined by the passport of products, the amount of substance in the tank does not depend on us, and the volume of the pipeline is calculated by the formula:

V =? * R? * L * 1000, where:

- ? = 3.14;

- R is the radius of the pipe in meters;

- L is the length of the pipeline.

Finally, we can not ignore the fact that the heating system is laid in residential and public buildings, where people are constantly. This means that the heat carrier must be acceptable from the point of view of fire, toxicological and chemical safety.

So, to summarize all that has been said.

The coolant must meet the following requirements:

- Have a high heat capacity and thermal conductivity;

- Have an acceptable temperature range of the liquid phase;

- Have a low viscosity with sufficient surface tension;

- Possess low corrosivity and chemical inertness;

- The liquid should be as safe for humans as non-flammable and non-toxic.

Note! Strict requirements for the composition and properties of the coolant limit the list of substances used quite strongly: as a rule, this is either distilled / tap water or water with the addition of antifreeze and additives.

Species

Water

Water is one of the most commonly used types of heat transfer fluids for heating systems. This is due to its extremely widespread, affordable and cheap.

But these are not all the advantages:

- Water has the highest heat capacity and a sufficiently high thermal conductivity;

- The fluidity of water can be attributed to substances with low viscosity;

- The substance is absolutely safe for humans and the environment;

- The liquid phase is in an acceptable temperature range;

- Corrosion activity of purified water is quite low;

- Does not burn, does not explode, does not enter into dangerous reactions.

Note! Distilled and demineralized water could be called an ideal coolant, but there are a number of drawbacks that force us to look for ways to optimize the properties of this substance.

The main lack of water is its ability to freeze at negative temperatures with a sharp expansion, as a result of which the system's vessels rupture. This means that heating should work smoothly in winter, which is not always acceptable.

Another property of water is the ability to dissolve most chemical compounds, especially salts and minerals. As a result, when the temperature changes, these compounds precipitate and are deposited in the form of plaque on the pipe walls, narrowing their clearance and reducing the thermal conductivity of the walls by several times.

Note! To combat the drawbacks, water is mixed with various substances - antifreeze, additives, additives. You can do it yourself, or you can purchase a finished product.

Antifreeze

Antifreeze is antifreeze coolant with a package of anti-corrosion and emollient additives. The most common and available complex based on ethylene glycol.

The addition of glycols significantly lowers the crystallization temperature of the mixture, and the range of the liquid phase expands to values from - 30 to + 130 degrees. At the same time, even when freezing, an increase in volume does not exceed 1.5%, which is safe for structural materials.

The use of antifreeze reduces the corrosion rate of metals by two orders of magnitude or more, but there is some toxicity of ethylene glycol. More modern and less toxic is propylene glycol, the physical properties of which are similar to ethylene glycol, but the price of this substance is twice as high.

Another safe component of antifreeze is glycerin. The use of food glycerin is absolutely safe for both humans and materials of the heating system.

The disadvantages of antifreeze include their higher viscosity and lower surface tension. This imposes special requirements for circulating pumps, valves, gaskets and other elements of the system.

The most high-quality products are produced by such companies as Clariant, Arteco, BASF, DOW Chemical.

Note! To understand how to choose a coolant, it is necessary to determine the mode of operation of heating in winter time: water is suitable for permanent work, and for rooms with occasional use (cottages, cottages, guest houses, etc.) antifreeze is better suited.

Conclusion

Many parameters of the heating system depend on the choice of the heat carrier; therefore, it should be chosen at the design stage. The most commonly used tap or distilled water, as well as antifreeze with an additive package. The video will help you not to make a mistake in choosing a coolant.