Heating a private house with wood - returning to the basics

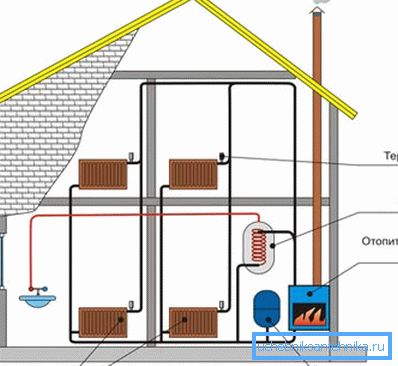

Far from civilization, stove heating is the only way to heat a house, because it does not depend on the proximity of gas mains and the whims of the electrical network. The ingenious connection of the furnace and the boiler turned the heating of a private house with wood into a fundamentally new process.

In this case, in addition to high heat transfer, the heating device also has a good appearance.

Wood stove evolution

The principle of operation of a wood-burning stove is simple - a portion of firewood is laid in the firebox, where it burns, spreading heat through the rooms. Firewood is an environmentally friendly fuel, much cheaper than gas. The advantage of such a stove is the ability to melt it at any time, not depending on the schedule of heating seasons utilities.

The inconvenience can be caused by constant monitoring of the process, when it is necessary to toss fuel and regulate traction.

More serious disadvantages include:

- uneven distribution of heat;

- large dimensions of the furnace;

- floating fuel price;

- danger of carbon monoxide poisoning.

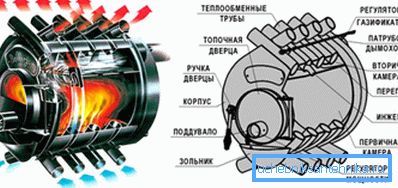

Air heater gas-generating furnaces Buleryan are largely devoid of these problems. They heat up the room in less than half an hour. Combustion gases rise from the lower chamber to the upper injector, where they are completely neutralized. Due to this, the efficiency of the unit is up to 85%.

The beautiful design of the fireplace stoves (fireplaces) allows you to naturally fit them into the interior of any room, and the flames behind the transparent door create a special comfort. Caminophenes combine the convection principle of the fireplace and retain heat like a conventional stove, the efficiency is up to 79%.

What you need to know about boilers

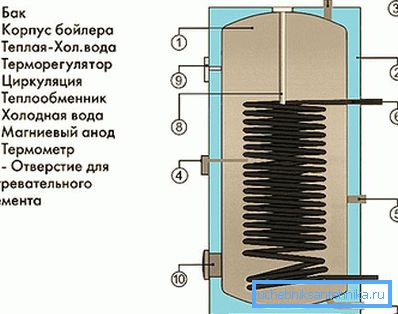

Most of the flaws in the stoves can be eliminated by using an improved heating device - a boiler for heating a private house with wood. Leaving the same raw material as fuel, the principle of space heating is fundamentally changing. Heat carrier is steam and water, which can be used for household needs.

Note! Choosing the power of the boiler, note that on average every 10m2 an apartment area with a ceiling height of up to 3 m will require about 1.2 kW for heating.

By type of fuel and the principle of combustion, boilers can be divided into types:

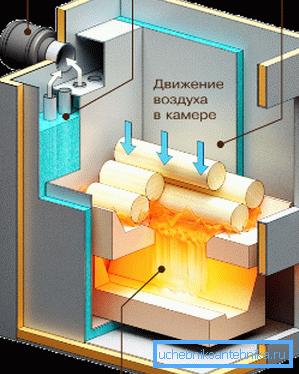

- Classic wood-fired boilers are inexpensive and wood waste as well as coal may be added to wood.. Burning time on one load takes about 4 hours.

- Pyrolysis units need only wood. The principle of operation is burning wood in conditions of low oxygen content. Firewood is burned in one chamber, in the second - pyrolysis gas emitted by them. The combustion of each tab is about 10–12 hours, and the efficiency is 90%.

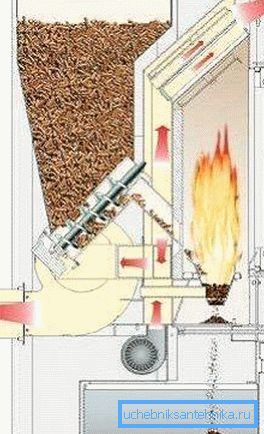

- Pellet-type boilers are remarkable for the complete automation of work from laying fuel to maintaining the combustion process. Depending on the volume of the bunker, the burning time lasts. Instructions for working with the boiler involves the use of only one type of fuel - pellets, which are quite expensive.

The material of which the heat exchanger is made is important. Usually for this I use steel or cast iron. Steel boilers are more efficient than cast-iron ones, they are lighter and smaller, moreover, their cost decreases slightly. Constructions made of cast iron, on the contrary, having lower efficiency, are more durable and more reliable than steel.

Paying much more expensive, you can afford a model of solid fuel made of heat-resistant steel grades. In addition to high temperatures, they are not subject to aggressive environmental influences.

Water and fire in one harness

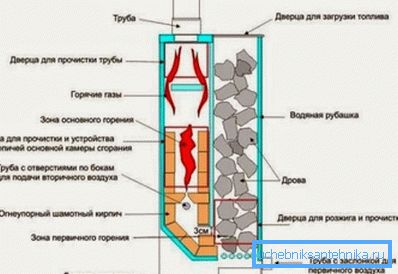

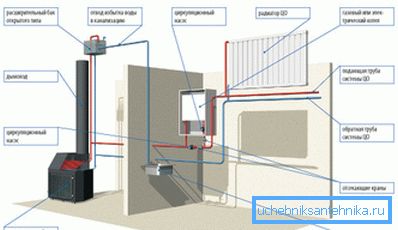

One boiler for heating a private house on the wood, being included in the water / steam system, can heat the whole house. The firebox is under the heat exchanger and its heating is intense only in the lower part. Therefore, the flow of coolant into the pipeline begins with a delay, reducing the efficiency of heating.

As an option, you can consider this version of the heating system:

- The walls of the boiler are double at a distance of 3-5 cm from each other and between them coolant circulates.

- Rapid heating and constant circulation of water prevents it from stagnating, increasing heat transfer by a quarter compared to the above structure.

The water contour of steel pipes passing through the coil along the upper and lateral parts of the chamber is no less effective. The undeniable advantage of such a circuit is its convenient repair. One leaky pipe is not difficult to replace, and from a financial point of view it will not be too costly.

Control of boiler operation

Adjusting the water temperature of the water circuit is carried out using a thermostat connected to a lever. The second end of the chain goes to the flap valve. When the desired temperature is reached, the thermostat turns the lever that opens the valve.

More advanced systems regulate the forced injection of air into the firebox with the help of a fan built into the duct. Air increases smoldering fuel that burns without residue. Monitoring the forced circulation of water will keep it warm even after burning.

The disadvantages of wood-burning units include:

- in some cases, difficulties with the replacement of components and maintenance;

- the complexity of ignition with incomplete heating;

- some models are demanding on the moisture content of the fuel;

- require more space for installation compared to conventional wood boilers.

Wood heating a private house with their own hands - the task is doable even without the help of specialists.

This will require a simple set of tools and materials:

- steel 5 mm sheet and corner;

- pig-iron grate;

- water conduits made of steel of different diameter;

- doors for firebox and ashpit;

- furnace dampers;

- stainless steel sheet for heat accumulator;

- sand.

- welding machine;

- Bulgarian;

- pliers and forceps;

- electric drill;

- level, roulette, squares.

Note! Using ordinary steel, it is better to make double walls of the firebox, so as not to burn out. And it is better to cook stainless steel water tanks at the factory.

The installation of the heating device should be performed in this order:

- The dimensions of the parts from the drawing should be transferred to the metal and the grinder cut the walls of the firebox and the holes for the doors.

- The stiffening ribs will be made of the profile pipe, and reinforcements of the joints of the furnace parts from the corner.

- Water pipes for the heat exchanger will have to be welded, and so that the surface of the circuit is maximum.

- Then lay the foundation of the refractory brick and the bottom of the ash pan on it.

- Boil the inner walls of the boiler along the perimeter.

- Put the grate bars on the welded guides inside the body.

- Mount heat exchangers.

- Stiffeners (rectangular profile) weld the outside to the bunker vertically.

- Install the outer walls and fill the gap between them and the inner.

- Install the top plate, place stainless steel containers on it and connect to the contours.

- Install the doors.

Summarizing

Depending on the type of heating device - stove or boiler, the efficiency of these objects will vary. Making solid fuel "heart" of the water system, you can get an autonomous heating station. The use of firewood gives independence from energy and gas supply.

The video shows an example of a powerful pyrolysis heating boiler.