Heating and cooking brick ovens - universal devices for a

Construction stores are ready to offer customers modern metal ovens for every taste, but despite this, many still prefer brick. This is due to their advantages, which attract consumers, one of which is the high heat capacity of the heater. After complete combustion of fuel, a brick furnace is capable of giving heat to the atmosphere of a room for quite a long time.

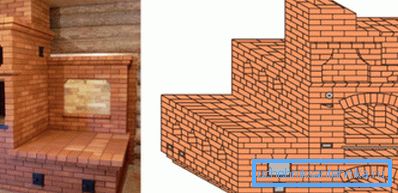

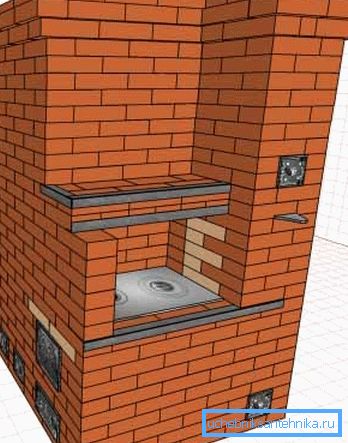

Today we will consider a hybrid option - heating and cooking.

This design provides a place for cooking. It is this option, so even with the bench, can often be found in fairy tales and stories of past years. The brick surface is not heated to such an extent as the metal, so the heat from it emanates softer.

It helps to cope with various diseases of the joints, if periodically heated them on the bed. Another fact is that beautiful and reliable brick heating stoves in the house are its decoration.

Device

Before proceeding further, it is necessary to find out what elements the heating and cooking device consists of:

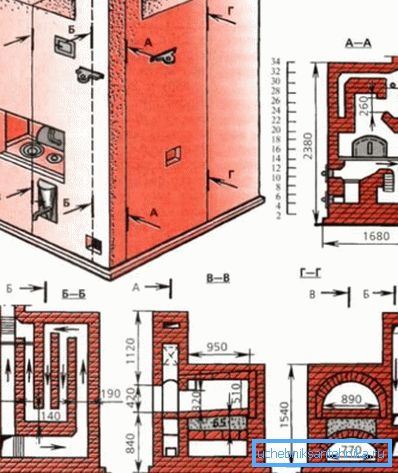

| Firebox | The main part of any furnace. Its dimensions depend on the basic design, so they do not have certain sizes. For example, if brick heating boilers are compact, the furnace should be made small. Above it, in our construction a slab is placed - from the floor about 900 mm so that it can be conveniently used. Therefore, it should be located below normal. |

| Blew |

|

| Cooktop |

|

| Oven | In classic furnaces, the element is combined with a firebox. If this option is chosen, then the distant part of the firebox, which often has a second door for its maintenance, is loaded with firewood, and cooking is carried out closer to the mouth. But, most often it is arranged separately from it in a masonry niche or in the form of a closed metal box, located next to the firebox. Now the oven is often completely isolated from the furnace space, so that smoke does not penetrate into it. The decision will not allow "to torment" dishes in pots, as it happens in classical models. But heating brick cooking stoves become compact, and it is now easier to maintain the oven, which is separate from the firebox. |

Tip: removable circles on the hob must be well adjusted to each other and the base so that the smoke through the cracks do not penetrate the room.

We increase work efficiency

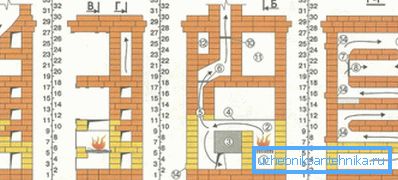

If you make the chimney straight, the products of combustion in this case directly from the combustion space will escape into the atmosphere. The efficiency of such a furnace will be at 50%. To increase the efficiency of the device, it is necessary to take maximum advantage of the thermal energy of hot gases.

Therefore, for this you need:

- Pre-pass them through the channel system. The latter are usually vertical, although there are horizontal ones, and the gases first move along them, and then get into the straight section of the chimney, which leads to the roof. During their outward movement, they release into the atmosphere of the room most of their thermal energy through the heating of the brickwork. Due to the additional heat in the channels, the efficiency of the device can reach almost 80%.

Advice: consider, the longer the smoke circulation will be, the better the thrust on the roof should be.

From the length of the channels depends on the efficiency of heat recovery from fuel combustion. Taking into account the fall of the chimney with the complication of the chimney, we do not recommend doing more than 2 vertical revolutions in one-story houses.

- To adjust the thrust valve or gate, which is located on the vertical section of the chimney for the channels.

Tip: The operating manual recommends that if the furnace is not heated during the cold period, the valve should be completely inserted into the pipe, otherwise an additional draft will be created.

After calculating the optimal ratio of the dimensions and proportions of the fuel chamber, the configuration of the smoke channels and the cross-section of the chimney, you will receive a heating and cooking stove that can support burning for a long time. The efficiency of combustion of solid fuel will be maximum, the air supply by the blower and the thrust level of the valve can be adjusted so that one bookmark of firewood with moderate intensity of combustion will last for several hours.

Kinds

Brewhouse heating stoves made of bricks come in various forms.

Let's stop on often used:

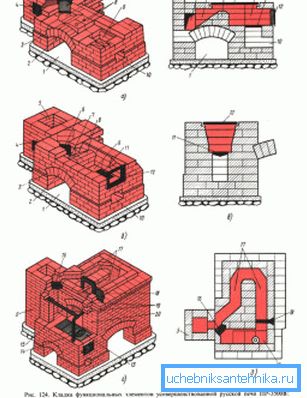

- The Russian advanced model absorbed a whole array of developments based on the traditional design.. Heat allows you to keep a massive masonry for a long time, distributing it evenly throughout the room. Such a large stove is heated infrequently, and the food from the oven has an incredible taste.

A popular solution is the extension of an additional firebox with a steel plate on the side of the fuel chamber fuel chamber. The second chimney usually goes into the main chimney separately. In this case, additional horizontal channels or convective bends are made in brick.

You can use the model in 2 modes:

- in the cold use the main combustion chamber;

- in the off-season for heating is quite less.

The improved Russian stove absorbed all the advantages of the classic model, while expanding the functions of cooking.

Disadvantages:

- large dimensions of the structure;

- high price of the device.

- Heating and cooking model with a water circuit that can be built in place of the oven or directly into the fuel chamber, keeping all the elements. With it, you can create an additional heating system with radiators that are installed in places where the heat from the furnace does not reach.

It is also used to heat water. In this case, the heat exchanger is made of steel in the form of a register, you can also use a hot water tank. One of the easiest options is to use an old cast iron radiator.

- Swede - demanded heating and cooking model of the furnace. It happens that they are called "Dutch", but this is wrong. Those are not used for cooking, and are intended only for heating. Often they were used as additional heating devices for Russian stoves, for more intensive heating of the premises.

If you decide to build a "swedish" with your own hands, we recommend immediately designing it with an oven. This option will appeal to those who love to cook casseroles and pies.

Universal solution

The devices considered today can be used not only in cold time, but also in summer. To do this, they have a special valve that allows you to use one combustion chamber for different purposes.

For the manufacture of the furnace, in addition to drawing and ordering, it is necessary to prepare tools and materials:

- red brick (the amount depends on the volume of the furnace);

- doors - furnace, clean, blower;

- cast iron stove with a burner;

- oven;

- grate;

- gate valve;

- steel strip;

- prefire sheet.

Select the size and number of devices in accordance with the dimensions and design features of the device. Tools - the usual set of brickwork.

Tip: when building a furnace, it is imperative to make a foundation and waterproof it.

Conclusion

At the cottage or in a private house brick oven with the function of cooking will be a real one-stop solution. You can make it yourself or invite a stove-maker. In any case, you will receive a unique device that can be used at any time of the year.

The video in the article will help you find additional information on this topic.