Heating and cooking stoves for summer cottage: a universal

Ovens with a cooking hob for cooking are becoming more and more popular among summer house owners. They combine two devices in themselves and thanks to this, they save space in small country houses.

Heating cooking stoves for giving can be made independently (as a rule, from a brick) or you can buy a ready-made metal device.

Homemade brick device

The unit must be small in size, because it will heat a small building with an area of up to 50 m2.

Principle of operation and design

- The outer walls of the furnace can be laid out in half-brick.

- In the design of the unit should include an oven and water heater.

- As a hob, you can use a plate of cast iron, at least with two burners.

- The furnace must be covered with a sheet of iron to improve heat transfer. Above, above it should be placed camera for cooking.

- The oven can be equipped both on the right and on the left of the furnace, based on the conditions of the room.

- For a small cottage will be enough stove, consisting of 14 brick rows.

- Heating must be done lower. It is hygienic and efficient.

The principle of operation of this unit below.

- In the summer, the hot gas from the firebox passes under the cooking stove, heating it and the oven. Then it is released into the atmosphere through the chimney.

- In winter, the work of the stove is almost the same. But the gas, after heating the hob, goes through the heating pipes into the upper closed box and heats it. Only then the coolant goes into the chimney.

Materials

Before you start working with your own hands, purchase the following.

- 230/250 pieces of kiln (refractory) brick.

- 200/210 kg of chamotte clay for solution.

- 200/210 kg of pure quartz sand of fine fraction.

- Metal corner, size 45? 45? 3 mm.

- Steel strip 40? 3 mm.

- Fireplace door. In our example, its dimensions are 270? 300 mm.

- The door for the blower, the dimensions of 150? 270 mm.

- Cooking surface of cast iron with hotplates.

- The slide valve.

- A box for heating water, sizes 500? 350?

- Drying analogue, ranging from dimensions 350? 350?

Note! If you do not have experience with masonry, please note that it is necessary to comply with its order. For this we need her drawings. Either order them from specialists or look on the Internet, including on our website.

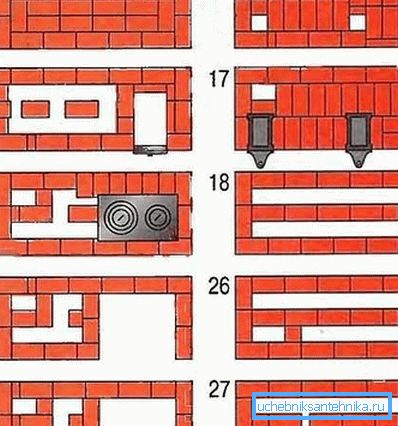

Masonry furnace

First, it will be necessary to equip the foundation of the unit. It is poured standard.

Next is the brickwork.

- Begin the initial and subsequent series completely. At the ends of the first row, place only whole bricks. In the center you can put and fight.

- The second layer is mounted only in whole blocks.

- 3/5 rows are the basis for the ash pan. At this level, its door is mounted, and on the 5th row (above) the overlap is arranged. A place for a drying chamber is immediately formed. Its size should correspond to the existing box for drying.

- Further from the sixth level, the basis for the grate begins to build up.

- On the seventh row of bricks she sets herself, and then the door of the fuel chamber.

- Level 8, 9 and 10 of the row - this is the place under the furnace. Immediately laid out the area for the drying box.

- On the 11th row (on top of the dryer) steel strips are laid. They are filled with sandy-clay solution. It is also necessary to choose a place for the arrangement of the chimney.

- At the 12/13 level, bricks are placed on the laid mortar, and a nest is prepared for mounting the hob.

- Next, the stove itself and the tank for heating the water (it will partially block the chimney).

- At the level of the last 14 rows, a pipe is installed for removal of combustion products.

Industrial units of metal

The most effective of industrial heating-cooking devices are cast-iron analogs of long burning. They are spared from the main drawback of solid fuel structures - the frequent laying of fuel. The instruction states that such units are able to work half a day on one portion of the fuel.

Choosing a cast iron stove

Selecting the unit, consider such moments.

- Furnace capacity. Cast iron aggregates of long burning can create a comfortable temperature regime in rooms with an area of 80/150 m ?. The declared capacity (maximum) of some of the models is enough to heat up and 250 m ?.

- The type of fuel used is also an important factor. The best option is to choose a universal stove that can be heated with all types of solid fuels: coal, wood, wood and peat briquettes, pellets. Its price is not much different from ordinary analogues.

- Optional features of the unit are important for the reliability and ease of use of the device. For example, you can load the fuel manually or automated. It is also possible to regulate the heat transfer of the furnace using the built-in thermostat.

- Stoves with a hob do not have a water circuit, so they are not tied to a specific area of the building.

- Modern designs to remove smoke make it possible to install a stove anywhere in the selected room.

Note! The cast-iron heating stove with a built-in hob does not need to be connected to the heating system of the house. It heats the rooms with air convection. This method is good because it achieves high performance and efficiency of the stove.

Conclusion

By purchasing a stove that has a cooking surface, you solve two problems at once - you can warm your dacha and get rid of the problem of cooking. The video in our article carries a lot of interesting information.