Heating and cooking stoves of long burning: design features

With the onset of winter, each owner of a small country house, which is located at a certain distance from the lines of communication, thinks about how to heat the room. At the same time, it is possible to combine the device for heating the air with the hob, in order to significantly expand its functions and reduce costs. It was for these purposes that a long-burning cooking stove was created.

Design and principle of operation

First we need to say that it will be about special designs that are specifically designed to burn out fuel for a very long time. At the same time it is possible to exercise independent control over this process. The fact is that this is a very important point if it is planned to prepare food on the product.

Design features

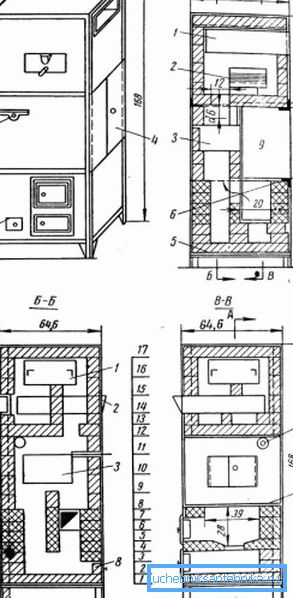

- First of all, it is worth mentioning that the furnace in such systems is divided into two or more sections that are significantly larger than conventional furnaces.. That is why their price is sometimes much higher, especially when you consider that usually these parts of the device are made of steel with a thickness of 3 to 5 mm.

- It is also necessary to note the fact that such a furnace has a lot of additional dampers. The fact is that due to them the access of air to the flame is limited and the burning process is significantly slowed down. Simply put, the fuel begins to smolder, which means that even the most common firewood will be able to feed the structure in about 12 hours.

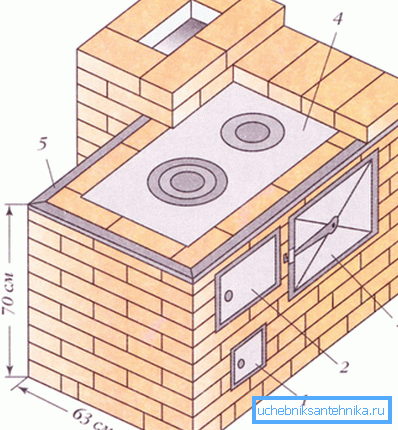

- If the heating furnace of long burning is equipped with a hob, then this part is usually mounted on the upper part of the firebox, which is freed from the protective coating. The design of this element is significantly different from that used in conventional furnaces, since it involves a closed combustion system, where heat is transferred through a special exchange.

Tip! The type of construction and its dimensions need to be selected based on the type of room and its volume. However, it must be immediately said that such products are not designed for large buildings or rooms.

Features of work

Usually, the instruction manual for such devices is written individually, for each model separately. This is due to the design features and other characteristics of the furnace. Therefore, we can describe only the general principle of operation.

First of all, it should be understood that the entire process, which is controlled in the first stages of combustion, requires the participation of the user. First you need to open all the dampers and ensure the flow of air. So the fire will very quickly begin to absorb fuel, which, with maximum acceleration, will raise the temperature in the room and create coals that will support the rest of the smoldering process.

In normal mode, all dampers must be closed. So the process of heat will take the maximum possible time.

If you need to start cooking, in some models for this you need to open the corresponding cap, which will begin to transfer the heat to the hob. Other structures do not need such actions, since the area for cooking is actually the upper wall of the firebox itself.

Tip! When purchasing such a furnace, be sure to read the instructions that come with it. Do not rely on your personal knowledge, even if the design seems familiar.

Recommendations of the masters

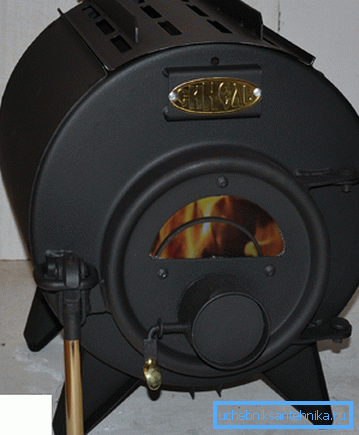

- If the furnace is made by hand, then it is worth using metal furnaces of factory production, which will later be sewn up with bricks. This will save a lot of money and effort.

- Even this design should not be left for a long time without supervision. Careless treatment of such systems very often becomes the cause of fires.

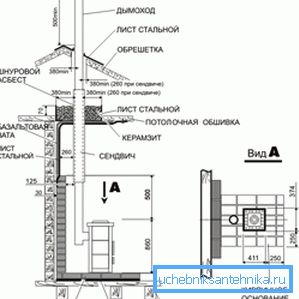

- Usually these furnaces are located in the middle of the house, so that its parts are in different rooms and warmed up the walls.

Conclusion

Having studied in detail the video given in this article, one can come to the conclusion that these types of furnaces are very economical and allow not to supply fuel for a long time. Considering these features, it is these structures that have become the most popular lately, and the principle of their work is actively used for many modern products of similar purpose (see also the article Igor Kuznetsov's Heating and Cooking Stove: main characteristics and recommendations for self-laying).