Heating boiler piping scheme: mandatory and additional

What are the required elements should include boiler heating strapping? What ensures the safety of system operation? How to organize low-temperature heating? In our material we will try to answer these questions.

Required items

The list of equipment is determined by the type of heating system.

Circulation type

Forced circulation implies the presence of a circulation pump for the heating system at home.

It is completed:

- Gryazevikom, installed in front of the pump current coolant;

- A pair of shut-off valves, allowing to clean the sump or dismantle the pump with minimal loss of coolant.

If the system operates alternately with forced and natural circulation, there should be a bypass with inserts between the tapping inserts with a cross-section equal to the filling cross-section. It is equipped with a ball check valve or valve that prevents the reverse flow of water through the bypass during pump operation.

Open and closed systems

An open heating system communicates with the atmosphere through an open heating expansion tank.

It combines several functions:

- Compensates an increase in the volume of coolant when heated.

- Serves for removal of the air forced out in it.

- Allows to add water instead of the system which has evaporated or boiled away in the course of work.

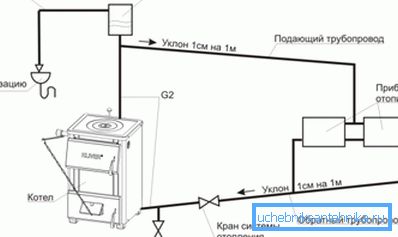

Note: an open tank is always mounted at the top of the contour. Pouring should have a constant slope from the tank, which will provide the natural current of the cooling coolant and allow air to be forced upwards.

In addition, the scheme of binding solid fuel boilers in systems with natural circulation includes an accelerating collector - a vertical bottling section connecting the boiler with an expansion tank.

In a closed system, the functions performed by the open expansion tank are assigned to several devices.

| Device | Functions |

| Diaphragm Expansion Tank | Compensation for increasing the volume of coolant during heating |

| Safety valve | Bleeding of excess pressure in the case when the expansion tank does not contain excess volume of coolant |

| Manometer | Monitoring system pressure |

| Automatic air vent | Removing air from the circuit |

When installing the system with your own hands it is useful to know a few subtleties.

- The expansion tank can be mounted at any point in the circuit; however, it is better to choose a place where the coolant flow contains a minimum of turbulences. For example, in front of the pump, about 10 diameters of filling from it.

- It is advisable to install the tank nozzle up. What is the reason for the instruction? Since in this case there is guaranteed no air in the tank on the other side of the membrane where the coolant should be.

- The volume of the tank is taken approximately equal to 10% of the total volume of the coolant in the system. The simplest way to estimate its quantity is to fill the circuit with water and drain it into any measuring dish.

- If there are several membrane tanks in the system, their volume is summed up.

- Continuous operation of the safety valve during operation indicates that the expansion tank is too small.

- Regardless of the presence of the air vent, the upper points of the heating system (upper radiator plugs, jumpers between them, etc.) are completed with air vent. In their role may act as Mayevsky's taps, as well as ordinary valves or water faucets.

Outside and inside the boiler

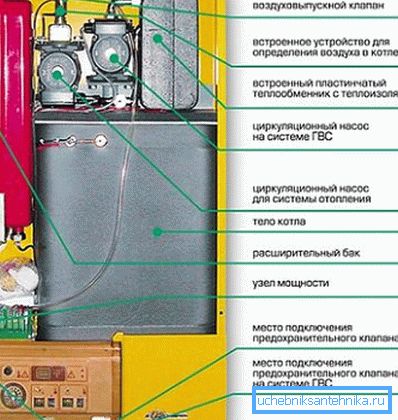

Often, the heating piping schemes may differ significantly from those described above. The fact is that many heating devices are equipped with their own circulation pumps, a security group, and often an expansion tank.

With this configuration, the scheme of the wall heating boiler piping includes, in essence, only a couple of valves that cut it off, discharge into the sewer system and a jumper with the cold-water system for filling the circuit.

Additional elements

What else can be included in the boiler strapping?

Collector

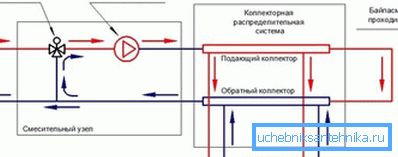

A manifold, or comb, is an uncomplicated device for parallel connection of several heating devices or independent circuits. Collectors are mounted on supply and return pipelines. Each pair of taps is provided with a shut-off valve and a throttle for adjustment.

Hydro Arrow

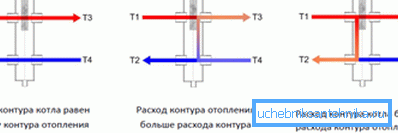

It is a type of reservoir and is fundamentally different from it only in significant internal volume. The hydraulic needle is connected to both the feed and return lines.

Separation of flows in the total volume allows redistributing the coolant between the flow and return flow; moreover: through additional branches it is possible to select water with temperatures intermediate between both threads.

Three way valve

This is a tee with a controlled valve, which works on the principle of either or: it allows you to open the coolant flow from the direct pipeline, reducing the flow of water from the return, and vice versa. What is it used for? First of all - for the organization of low-temperature contours.

The fact is that for a solid fuel boiler the temperature of the return pipe below 50 ° C is extremely undesirable: the price of excessive cooling of the heat exchanger is the formation of condensate on it, dramatically reducing its service life. When operating in normal mode, with supply and return temperatures of 75/55 C, a circuit with a separate circulating pump is created to power the heated floor.

Some of the return water from this circuit is recycled; at the same time, the three-way valve doses more hot water from the boiler depending on the temperature of the heat carrier. As a rule, such a scheme for tying a solid fuel heating boiler includes a thermostatic head, which is responsible for temperature control.

Heat accumulator

Under this name hides a thermally insulated water tank of considerable volume. It allows you to store a large amount of thermal energy and gradually give it to heating appliances.

Heat accumulator is useful for stabilizing the temperature of radiators when using solid fuel boilers; it often also includes the piping of an electric heating boiler, which operates exclusively at night, when a cheaper electricity tariff is in effect.

Conclusion

We hope that the information offered to the reader will help him in the design and construction of his own heating system. As always, the attached video contains additional thematic materials. Successes!