Heating boilers for liquid fuel: the device and features

Heating boilers for liquid fuel in our time occupy a decent niche in the market of equipment for heating systems. This is due to the fact that they are a good alternative to gas boilers in areas where there is no gasification, moreover, if necessary, they can be converted to work on gas. In this article we will get acquainted with the device of these boilers and their main features.

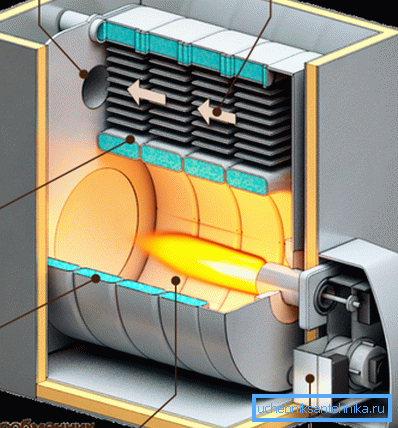

Boiler arrangement

Basic elements and principle of operation

Oil-fired boilers work on the same principle as gas equipment, the only difference is in the burner, which is also called the nozzle.

As a result, they consist of the following structural elements:

- Combustion chambers;

- Burners (universal or diesel);

- Heat exchanger;

- Fuel filter;

- Enclosures;

- Chimney;

- Electronics, which is responsible for the operation of the apparatus.

The process of the device is as follows:

- The burner enters the fuel through a pump and mixes it with air;

- The mixture then enters the combustion chamber, where it ignites;

- The torch heats the walls of the combustion chamber, which are the heat exchanger;

- The heated heat exchanger in turn heats the coolant.

To improve the efficiency and performance of the device, inside there are a lot of chimney tubes and heat transfer plates. Therefore, oil-fired boilers have a sufficiently high efficiency.

In addition, it should be noted that diesel fuel in the combustion process generates more heat than, for example, gas or solid fuel. Therefore, this equipment can work in heating systems installed not only in residential buildings, but also in production facilities.

Moreover, modern boilers allow heating with minimal human participation, since all processes are automated. In particular, the device itself sucks diesel fuel from the tank in the required quantity.

Note! According to existing regulations, the volume of capacity for fuel should not exceed 50 liters. If the tank is larger, it should be located in a separate room.

As a rule, in addition to diesel fuel, such a flammable liquid can be used as an energy carrier for heating boilers as:

- Waste oil;

- Biofuels;

- Fuel oil;

- Kerosene.

Due to this, the owner of the equipment has the opportunity to use the most affordable liquid fuel.

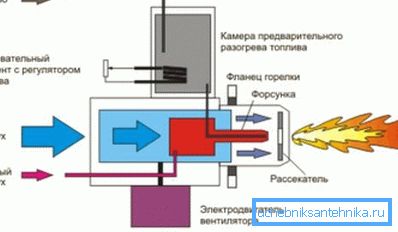

Nozzle device

The most important element of this equipment is a liquid fuel burner. Its task is to mix air with a combustible liquid in the required proportions, as well as to feed the combustible mixture into the combustion chamber.

Note! Many models of oil-fired boilers are universal and are able to work not only with fuel oil, but also with gas, even without replacing the nozzle. This is especially convenient for people who are planning to conduct gas in the foreseeable future.

W / t nozzles by mode of operation are classified into the following types:

| Single stage | They work with a constant power, which can be changed only after the interruption of the apparatus operation. |

| Two-stage | They have two modes that can be changed while the boiler is running. |

| Modulated | Able to reach full operating power gradually. |

The main structural elements of the injectors are:

- Fan, which provides forced air.

- Fuel heating system. In some cases it is an extremely important detail, since the liquid for heating the boilers may thicken as the temperature decreases.

- Fuel pump for supplying fluid from the tank to the fuel line under a certain pressure.

- Servos, which allow you to adjust the fuel supply and the position of the air damper.

- Adjusting thermostat - ensures the start-up of the burner, as well as the temperature parameters of combustion.

- Nozzle - sprays fuel, and also provides the necessary conditions for the ignition of the mixture.

- Microswitch float - determines the level of fuel in the tank and, if necessary, turns off the device.

- Secondary air regulator, supporting the formed torch of burning.

- Burner control box - allows you to adjust the parameters of the device in the process.

It should be noted that in addition to the listed elements, the design of liquid-fuel nozzles always provides for the presence of flexible hoses through which fuel is supplied. In addition, there is a set of various sensors that monitor the main parameters of the device, such as fuel pressure, the presence of a torch, etc.

Note! Before testing the boiler after installation, it is necessary to pour fluid into the heating system, ensuring the necessary pressure.

Features of liquid fuel boilers

Merits

Heating fuel oil, like any other, has certain advantages and disadvantages.

Among the positive points are the following:

- To use the device do not need permission, as this equipment refers to household appliances.

- The possibility of installing their own hands, as there is no need to conduct a gas pipeline

- The equipment has a high efficiency, which reaches 95 percent.

- Minor level of air pollution - all combustible products meet environmental standards.

- Simple instruction manual, as almost all modern devices are equipped with automation. For the same reason, boilers can work for a long time without human intervention.

- As mentioned above, the possibility of conversion to work on gas.

As we can see, the equipment has many advantages and is quite versatile.

disadvantages

Among the disadvantages of the considered boilers are the following points:

- Great fuel consumption. Therefore, this type of heating is quite expensive.

- The boiler, together with a tank for fuel, takes up quite a lot of space.

- The need to monitor the operation of the system and from time to time to add fuel to the tank.

- The room must be equipped with an exhaust hood for removal of combustion products.

- During operation, the equipment produces a rather strong noise.

- The equipment requires power, as the device is controlled by electronics. Therefore, to work offline, you must use an independent power supply.

- For fuel it is necessary to use a special container, otherwise the unpleasant smell of fuel will spread inside the room.

Note! Oil-fired boilers, unlike other analogues, require proper maintenance. In particular, it is impossible to prevent the accumulation of soot on the walls of the apparatus, since this will complicate the working process of the device.

As a result of these shortcomings, you should estimate the pros and cons, as well as get acquainted with the features of electric and solid fuel boilers. For example, if you need an apparatus for the dacha, where there is a forest nearby, it is more expedient to purchase a solid fuel boiler. In this case, heating may be generally free.

Selection features

When choosing a heating boiler on liquid fuel, in addition to the general parameters of the device, such as power, functionality, etc., attention should be paid to the characteristics of the burner.

In particular, attention should be paid to the following points:

- A variety of choices of fuel, which can operate the device.

- The level of emission of toxic substances into the atmosphere.

- The level of noise and vibration during operation.

- Efficiency indicator (ideally should be 90-95 degrees).

- The stability of the combustion process due to the effective adjustment of the air supply.

Tip!

For private houses it is better to choose double-circuit boilers that heat the water not only for heating, but also hot water.

Of course, you should pay attention to the manufacturer of the device. It is advisable to opt for well-known brands, despite the fact that the price of their products is slightly higher than the devices from lesser-known manufacturers.

The most popular boilers of the following companies:

- ACV (Belgium);

- Lotos (Russia);

- Protherm (Slovakia);

- De Dietrich (France);

- Buderus (Germany);

- Kiturami STSO (South Korea).

It should be noted that the boiler and the burner to it can be purchased separately. This allows you to assemble the heating boiler on liquid fuel in accordance with individual requirements. True, the cost of heating equipment in this case will increase slightly.

Note! If a universal burner is installed in the boiler, the change of fuel is a responsible procedure. Before you do it, you need to clean the device from soot and combustion products.

Here, perhaps, all the main features of these heating devices that must be considered when choosing equipment.

Conclusion

Despite a number of advantages that boilers for liquid fuel possess, they are used less often than other analogues, which is associated with the high cost of their operation. Therefore, it makes sense to apply them in the case when it is not possible to use gas, coal or firewood as fuel.

From the video in this article, you can pick up some additional information on this topic.