Heating boilers for mining: exploring the prospects

Against the background of constantly increasing energy, people reluctantly begin to think about switching to more acceptable types of fuel. And here perhaps the most affordable option is heating oil waste. This choice is not accidental, economical Europe has long been heated in this way.

In fact, if you think about it, in this case there are much more advantages than disadvantages.

What is the secret of popularity

Naturally, the first thing that interests almost all consumers is the price of fuel or how much such heating will cost. From this point of view, the used oil is almost a gratuitous option.

Just think how many cars, trains, tractors drive around, ships, ships and other various vehicles. And they all need periodic oil changes.

It is no secret that the disposal of this product is a constant headache for many enterprises, because this procedure is not cheap, and if you pour it on the ground you will receive a serious penalty for pollution of Mother Nature. From here we draw a conclusion, if you have to pay for such happiness, then it is a mere penny, and with a reasonable approach, you can also take money for such recycling.

Important: statisticians say that at the moment in our great power with its volumes, only 15% of this valuable product goes for heating, another 15% is recycled. All other 70% simply pour out on the earth. It is not difficult to calculate the potential of this direction.

The main advantages of such heating

- Heating boiler to work almost omnivorous. The unit works equally well not only on the engine version of the fuel, but also on vegetable, as well as on all types of electrical oils.

- From the point of view of waste disposal, these units are not much inferior to boilers operating on liquid fuel or gas appliances.. The fact is that the heating boilers do not burn the crude oil itself, but its heated vapors, as a result, the product burns out almost completely.

- This product has a tremendous energy intensity and, when burned, emits a huge amount of heat.. The efficiency of these units is comparable only with electrical installations, it reaches 95%.

- The cost of purchasing equipment pays off in a maximum of 2 years and this is on condition that the best factory models with built-in automation will be purchased.. If you are satisfied with a simple boiler from a handicraft workshop, then it will pay off in a few months.

- The heating boiler for working off is a fairly simple design, if desired, it can be assembled in the home workshop with your own hands.. And almost all the nodes of this unit are made from improvised, accessible materials. These can be old pipes, gas cylinders and sheet steel. The assembly instructions are quite accessible to a person with a secondary education.

What are the disadvantages of such equipment?

- Heater for testing is not advisable to place in a residential area. First, open burners require a large flow of air and naturally oxygen is strongly burned out. But even if the burner is closed and the air is forced from the outside, the smell of oil in the dwelling will not please many people, so you will need to make a separate boiler room.

- Although oil, you can use whatever you like, but in any case it will need to be filtered. From here come the additional cost of filters.

- This type of fuel belongs to flammable compositions, so the boiler, storage and all that is connected with it, you will need to seriously equip all fire safety standards.

- And one of the most unpleasant moments is the need to clean the chimney from soot 1 - 2 times a month.

How do such units work?

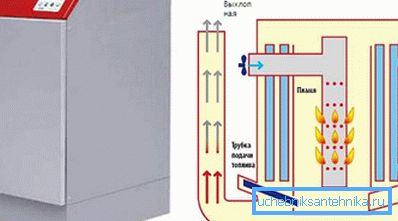

As mentioned above, the device of such devices is not overly complex. If to describe in general terms, the principle of operation of the boiler is somewhat similar to the principle of operation of an internal combustion engine.

Initially, the raw fuel enters the so-called evaporator. This is an artificially heated cylinder in which the fuel is heated to a temperature of intense evaporation.

The heated fuel vapors are mixed with air and forcibly, under pressure, are fed into the second chamber, where the actual oil burns out, giving the maximum temperature.

Subtleties of operation

The system of using the heat obtained can be varied. In the simplest version, something similar to a stove is mounted, the unit also heats up. It is possible to cook something on it or it is just heated nearby.

A positive point here is the relatively small size. Such a design can easily fit in the trunk of the car and take, for example, to the cottage.

More advanced owners build in the walls of the combustion chamber of the heater a heat exchanger through which water constantly circulates. All this miracle of technology is connected to a standard heating system with forced or natural circulation operating on a heat-transfer fluid.

Heating to work out can be organized more reasonably, ensuring a minimum amount of heat loss. But for this you have to buy a professionally made factory boiler. Now many are trying to establish the production of such equipment, but in the aggregate of all the characteristics, domestic producers and Finns are leading in the world market.

Tip: our equipment is considered more reliable and unpretentious in operation. Finland has focused on increased efficiency and a higher degree of purification of the exhaust. Given the price of fuel and sometimes harsh operating conditions, it is better to support the domestic manufacturer.

Heating boilers for testing, like most of these units, are available in two versions. Devices with one circuit are more aimed at heating, although if the system is equipped with a passive heating boiler, it can provide a small house and a family of 2 to 3 people with warm water. Double-circuit heating boilers can easily heat and give hot water to large cottages.

In the video you can find a lot of interesting material on the topic.

Conclusion

We talked about the use of this equipment for heating private housing. But return heating does not end there. The heating boiler on the return pipe can be installed, for example, in the service station and get completely free heat.

Enterprises can solve the problem of recycling mining, organizing greenhouses. Simply put, there is no limit to perfection.